Duplex Stainless Steel

Duplex Stainless Steel Related Searches

Super Duplex Stainless Steel Duplex Stainless Steel 2205 2205 Duplex Stainless Steel Stainless Steel Dumbbells Stainless Steel Vitamix Vitamix Stainless Steel Stainless Steel Stainless Stainless Steel Double Boiler Dark Stainless Steel Density Stainless Steel Colored Stainless Steel Inox Stainless Steel Cast Stainless Steel Discolored Stainless Steel Liquid Stainless Steel Metal Stainless Steel Stainless Steel Triply Stainless Steel Hardware Annealed Stainless Steel Stainless Steel Dildo Monochromatic Stainless Steel Fingerprintless Stainless Steel Drill Stainless Steel Stainless Steel Wall Stainless Steel Tupperware Stainless Steel Post Stainless Steel Coupling Stainless Steel Divided Plate Faux Stainless Steel Backsplash Stainless SteelDuplex Stainless Steel Supplier & Manufacturer from China

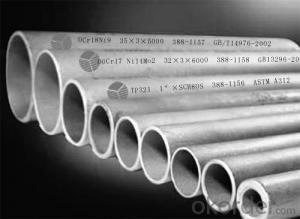

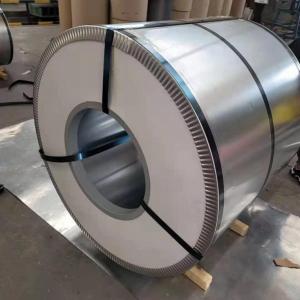

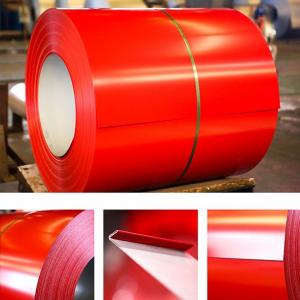

Duplex Stainless Steel is a unique class of stainless steel that combines the properties of both austenitic and ferritic stainless steels. This alloy exhibits excellent strength, corrosion resistance, and toughness, making it suitable for a wide range of applications. The combination of these properties allows Duplex Stainless Steel to perform well in environments where traditional stainless steels may not be sufficient.Duplex Stainless Steel is widely used in various industries, including chemical processing, marine, oil and gas, and paper production. Its high resistance to stress corrosion cracking, pitting, and crevice corrosion makes it an ideal choice for applications involving aggressive environments. Additionally, its high strength-to-weight ratio and excellent formability make it suitable for a variety of construction and engineering projects.

Okorder.com is a leading wholesale supplier of Duplex Stainless Steel, offering a vast inventory of this high-performance material. With a commitment to quality and customer satisfaction, Okorder.com ensures that customers receive the best possible products at competitive prices. Whether you need Duplex Stainless Steel for industrial applications, construction projects, or any other demanding environment, Okorder.com is your reliable source for this versatile and durable material.

Hot Products