BMT Z35 Rolled Prepainted Steel Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

BMT Prepainted Rolled Steel Coil is a kind of coated steel coil/sheet.

With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Zn coating on both faces by hot dip process.

Its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Specifications of BMT Z35 Rolled Prepainted Steel Coil for Construction

Product | BMT Prepainted Rolled Steel Coil for Construction |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.3-3.5mm |

Width | 600-1250mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z35-150g/m2 |

Technique | Raw material: Hot rolled steel coil > Cold rolled>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM |

Coil weight | 25MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

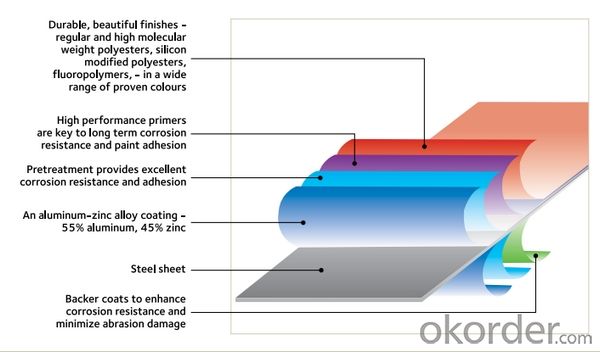

Structure of BMT Z35 Rolled Prepainted Steel Coil for Construction

Main Feature of BMT Z35 Rolled Prepainted Steel Coil for Construction

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

3. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of BMT Z35 Rolled Prepainted Steel Coil for Construction

1. Construction and building: roofing; ventilating duct; handrail; partition panel

2. Electric appliance: refrigerator; washing machine; refrigerator..

3. Transportation: oil tank; gas tank; road sign; etc.

4. Agriculture:barn; etc.

5. Others: vending machine; game machine; etc.

- Q:What are chemical properties of high speed steel? Physical properties?What is high speed steel used for? One interesting fact about high speed steel?

- wikipedia: High speed steel (often abbreviated HSS, sometimes HS) is a material usually used in the manufacture of machine tool bits and other cutters. It is often used in power saw blades and drill bits. It is superior to the older high carbon steel tools used extensively through the 1940s in that it can withstand higher temperatures without losing its temper (hardness). This property allows HSS to cut faster than high carbon steel, hence the name high speed steel. At room temperature, in their generally recommended heat treatment, HSS grades generally display high hardness (above HRC60) and a high abrasion resistance (generally linked to tungsten content often used in HSS) compared to common carbon and tool steels. see reference for more info .

- Q:Are steel coils resistant to rust and corrosion?

- Yes, steel coils are typically resistant to rust and corrosion due to their protective coating or treatment that prevents the steel from coming into direct contact with moisture or oxygen.

- Q:I have a steel plate 3' long x 2 wide x 3/16 thick. I have a 1/2 diameter hole with the center 3/4 from the end. Tensile strength is 38,000psi. A chain goes through the hole and is connected to a load. how does one determine how much tension the chain can have before it rips through the hole?

- Assuming that the chain can take the breaking load of the plate, the plate will fail at the area between the hole and the end, in double shear. The shear strength of the material should therefore be known for us to be able to calculate the breaking force. Approximately, the shear strength of steel is about 60% of the tensile strength. For ordinary mild steel the tensile strength is about 60,000 psi, not 38,000 psi. 38,000 psi is just about the yield point of mild steel. Using 60,000 psi tensile strength, the approximate shear strength of steel therefore is 36.000 psi. The net area between the hole and the end of the plate is: A = 3/16(3/4 - 1/4) = 0.09375 in^2 The force necessary to rip through the area which is also the tension on the chain is: T = 2 x 0.09375 x 36,000 = 6750 lbs

- Q:How are steel coils inspected for yield strength using tensile testing?

- Tensile testing is the method used to inspect the yield strength of steel coils. This involves subjecting a sample of the coil to controlled tension until it reaches its breaking point. Through this test, various mechanical properties of the steel, including yield strength, can be determined. To conduct the tensile testing for yield strength inspection, a small strip of the coil is cut and prepared. The strip is then placed in a machine specifically designed for tensile testing. This machine consists of two grips that securely hold the strip at opposite ends. Subsequently, the machine applies a steadily increasing force to the strip, causing it to elongate until it eventually breaks. Throughout the test, the machine measures the force applied and the elongation of the strip. The yield strength is determined by identifying the point on the stress-strain curve where the material begins to undergo plastic deformation, meaning it exhibits permanent deformation without any increase in load. Typically, the yield strength is reported as the stress required to cause a specific amount of plastic deformation, such as 0.2% or 0.5%. This value represents the maximum stress that the steel can endure without experiencing permanent deformation. By performing tensile testing on a sample of the steel coil, it becomes possible to ascertain its yield strength. This information is vital in ensuring the quality and dependability of the steel coil, as it indicates the maximum stress it can tolerate before permanent deformation occurs. Furthermore, this testing method allows for the comprehensive evaluation of other mechanical properties, including ultimate tensile strength, elongation, and modulus of elasticity, thus providing a thorough understanding of the steel's performance characteristics.

- Q:Iron too heavy for Ulysses but if there was any iron used id imagine it was steel. Can steel go deeper into sun than iron? Compare two bolts.. 1steel 1iron..is there a difference to what the steel can do?

- Dont understand are you going to put them in sun ? Sun made from gas wich is on fire. Its impossible to get to the sun and not to get burn. Steel is really more solid and strong than iron so its more hard to break it or to bend. But in camparing of fusion temperature - iron is a bit more better, though it would not make a big difference .From metals - tungsten has the highest fusion temperature - near to 3400 C . Iron is near to 1530 C, steel is near to 1300 -1500 C. So according to this tungsten can go most close to sun. Right near the sun temperature is millions of degrees so anything will fuse and burn there.

- Q:In what ways can steel fail in use of buildings ad what can be done to prevent it?

- we fireproof steel in buildings now if thats what your talking about

- Q:What are the best types of steel for swords

- The okorder /

- Q:What are the common defects in steel coil surface finishes?

- Common defects in steel coil surface finishes include scratches, pits, roll marks, stains, and unevenness. These defects can be caused by various factors such as improper handling, processing issues, or equipment malfunction. These surface defects affect the aesthetics and quality of the steel coil, making it unsuitable for certain applications or requiring additional processing to rectify the defects.

- Q:How are steel coils used in the production of rail tracks?

- Steel coils are used in the production of rail tracks as they are a primary raw material for manufacturing the rails. These coils are first processed to form the desired shape and dimensions of the rail tracks, which are then cut, welded, and shaped to create the individual rail sections. The steel coils provide the strength, durability, and flexibility necessary for the tracks to withstand heavy loads, extreme weather conditions, and constant use.

- Q:What are the advantages of using pre-painted steel coils?

- There are several advantages of using pre-painted steel coils. Firstly, they offer a wide range of color options, allowing for greater design flexibility and customization. Secondly, pre-painted steel coils have a protective coating that enhances their durability and resistance to corrosion, extending their lifespan. Additionally, pre-painted steel coils are available in various finishes, such as matte, glossy, or textured, providing aesthetic appeal. Furthermore, these coils are ready for immediate use, saving time and labor costs associated with painting on-site. Overall, pre-painted steel coils offer convenience, durability, versatility, and enhanced aesthetics, making them a preferred choice in various industries.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

BMT Z35 Rolled Prepainted Steel Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

Offcanvas right

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords