Water Well Drill Pipe with API Spec 5DP Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Water Well Drill Pipe Description

We can supply all kinds of drill pipes that are consistent with API SPEC 5DP. Advanced drill pipe production lines can transfer the welding parameters to the best position to ensure the quality of welding zone; the heat treatment process with the feature of internal and external cooling at the same time can make a more reliable and stable mechanical character. Application of automatic weight, length measurement and automatic spray records can ensure products' traceability. Application of thickening and heating lines and 1250 tons of upsetting machine can ensure the thickening size meet the standard of API SPEC 5DR Using of CN furnace for whole pipe body heating and quenching, tempering machine's advanced heat treatment process can ensure the pipe's mechanical character. Tube hydraulic straightening machine ensures the straightness and coaxiality of pipe body.

SPEC: Φ73x9x(9.5/6.1)m Pipe body material: DZ40、DZ50、R780、G105

SPEC: Φ89x10x(9.5/6.1)m Tool joint material: 40Cr、45Mn2、35Crmo、4137H

2. Main Features of Water Well Drill Pipe

1) Advanced test for quality

2) MTC provided

3) API Standard

3. Water Well Drill Pipe Images

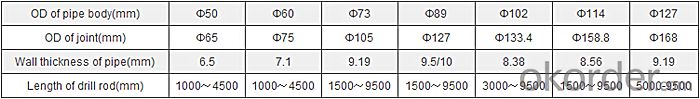

4. Water Well Drill Pipe Specification

5. FAQ of Water Well Drill Pipe

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

One of the leading manufacturers and suppliers specializing in drill pipe products in China, mainly offering drill pipes including oil drill pipe, water well drill pipe, flat drill pipe, geological drill pipe and non-dig drill pipe.

Other than drill pipes we are also capable of supplying a wide variety of pipeline accessories, drill joints, steel pipe fittings, valves etc. consists of our one-stop sales. The integrated sales & service ensures customers with various demands an easier access for purchasing management.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: Can steel pipes be used in plumbing systems?

- Yes, steel pipes can be used in plumbing systems. Steel pipes are commonly used for plumbing due to their durability, strength, and resistance to corrosion. They are suitable for both residential and commercial plumbing applications and can effectively transport water, gas, and other fluids.

- Q: Are steel pipes resistant to corrosion?

- Yes, steel pipes are generally resistant to corrosion due to their composition, which includes a protective layer of zinc or other anti-corrosion coatings. However, factors such as exposure to harsh environments or chemicals can affect the level of corrosion resistance.

- Q: How are steel pipes tested for quality control?

- Steel pipes are tested for quality control through various methods such as visual inspection, dimensional checks, non-destructive testing, and mechanical testing. These tests ensure that the pipes meet the required standards and specifications, ensuring their structural integrity and performance.

- Q: What is the maximum allowable stress for steel pipes?

- The maximum allowable stress for steel pipes depends on various factors such as the grade of steel, diameter, wall thickness, and the intended application. It is typically determined by industry standards and codes, such as the American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code. Therefore, there is no one-size-fits-all answer to this question.

- Q: How are steel pipes tested for leaks?

- Steel pipes can be tested for leaks using various methods, including hydrostatic testing, pneumatic testing, and using leak detection equipment such as ultrasonic testing or helium testing.

- Q: What are the different types of connections used with steel pipes?

- There are several types of connections commonly used with steel pipes, including threaded connections, welded connections, flanged connections, and grooved connections.

- Q: What are the common standards for manufacturing steel pipes?

- The common standards for manufacturing steel pipes include specifications such as ASTM A53, ASTM A106, API 5L, and DIN 1629/2448. These standards outline the requirements for the chemical composition, mechanical properties, dimensions, and testing of steel pipes used in various industries.

- Q: How are steel pipes used in seaport infrastructure?

- Steel pipes are commonly used in seaport infrastructure for various purposes such as constructing piers, wharfs, and docks. They are used for the foundation of these structures, providing stability and strength. Steel pipes are also used in the construction of underwater pipelines for transporting oil, gas, and other fluids. Additionally, they are utilized in the fabrication of fences, barriers, and railings to ensure safety and security within the seaport area.

- Q: What is a steel pipe?

- A steel pipe is a cylindrical hollow tube made from steel material, commonly used in various industries for transporting fluids, gases, or solids, as well as for structural applications.

- Q: What are the different methods of pipe joining using steel pipes?

- Some of the different methods of pipe joining using steel pipes include butt welding, socket welding, threaded connections, and flange connections.

Send your message to us

Water Well Drill Pipe with API Spec 5DP Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords