Self priming 6 inch diesel water pump with trailer

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 4 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Introduction

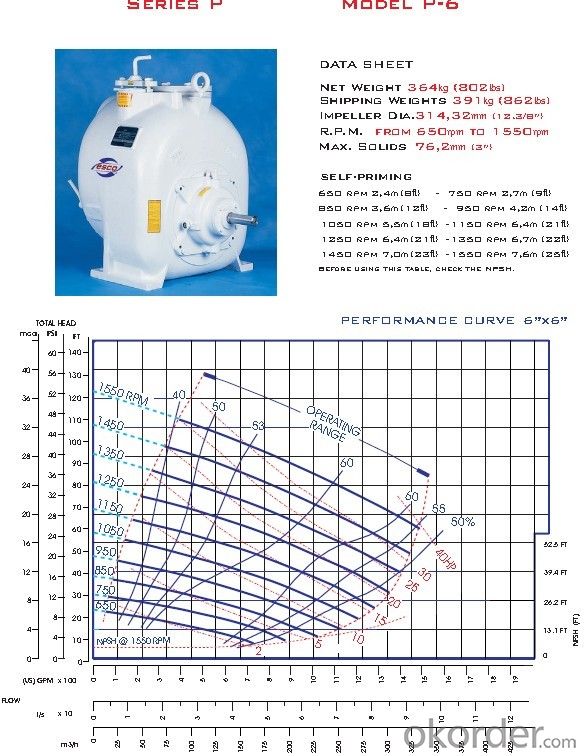

Main datas:

Capacity( flow rate) :35 ~ 310m3/h

Head :5~58 m

Speed:850 ~ 1950rpm

Impeller diameter:317.5mm

Pump weight:413kg /437kg

Power:5 ~ 75 hp

Advantage :

Big pump body pass 31.75mm solid ,high suction head 7.6 m

Convenient repair and clean (a person ten minutes)

Removable cover plate ,replaceable wear plate

OEM ,L/C ,TT ,O/A ,D/P,D/A and so on

CE ,TUV .ISO

NAME: 6 inch diesel water pump

Standard Self-Priming pump units are available for Solids Handling or Clear Liquid service. Typical mounting configurations are Engine Driven for Skid or Trailer Mounted packages and Frame Mounted Electric Driven. Pumps also are available in a variety of different metallurgies.

1) Main Character

1.Beautiful shape and fine structure,reliable performance.

2.With strong capacity of delf priming, no need to equip with flap valve.

3.Non-clog, and with powerful capacity of passing big solid..

4.The hole can make sure that stronger sewage can be cleaned quickly when pump is jammed.

5.The unique lubrication oil mechanical seal cavity makes the performance more reliable.

6.Special check valve structure can make the pump working quickly.

7. When working, the gas and liquid works together .

8. Low rotary speed,reliable operation,long time usage, easy to maintenance.

9.Advanced pressure protector make pump the pump work safe.

2) Application Area

1. Municipal project, sewage project, instruction project.

2.Uptown,hospital, hotel sewage transportation.

3.Classification of municipal sewage factory treatment and concentrate system engineering.

4. Factory and contaminated water delivery.

3) Industries Served

♦ Construction | ♦ Industrial | ♦ Municipal |

♦ Agricultural | ♦ Mining | ♦ Dewatering |

♦ Industrial Waste | ♦ Sewage | ♦ Oil Field |

♦ Petrochemical | ♦ Paper Mills | ♦ Processing |

4)Parameter

| 1.Inlet/Outlet | 2''(50mm), 3''(75mm), 4''(100mm), 6''(150mm), 8''(200mm), 10''(250mm), 12''(300mm) | |

| 2.Impeller Diameter | 158.74mm-457.2mm | |

| 3.Rotary Speed | 550RPM-2150 RPM | |

| 4.Flow Rates | 8m3/h-1275m3/h | 20GPM-5500GPM |

| 5.Head | 6m-63m | |

| 6.Horsepower | 1HP-125HP | |

| 7.N.W | 92KG-998KG | |

| 8.G.W | 114KG-1066KG | |

| 9.Solid Passing | 20.63mm-76.2mm | |

| 10.Material | Cast Iron, ADI, CD4MCU, 316 SS, Alloy 20, C276. | |

| 11.Diesel Driving | Water cooled or air cooled | |

| 12.Method of Connection | Self-priming pumps are available as basic units or may be flex-coupled, V-belt driven or engine mounted. | |

| 13.Drive Variation | Cummins, Deutz, Ricardo, Perkins or Chinese Diesel, Electric Motor | |

| 14.Skid Mounted on Trailer | 2 or 4 wheels Trailer/Trailor,Cart | |

| 15.Package | Exporting plywood case | |

| 16.Certification | CE , ISO9001:2008 ,TUV | |

5) Mounting Configuration

♦ Frame Mounted

♦ Base Mounted Electric Driven

♦ Engine Driven SAE Mounted

♦ Engine Driven Skid or Trailer Packages

♦ Horizontal or Vertical V-Belt Driven

Prameter

5) Mounting Configuration

♦ Frame Mounted

♦ Base Mounted Electric Driven

♦ Engine Driven SAE Mounted

♦ Engine Driven Skid or Trailer Packages

♦ Horizontal or Vertical V-Belt Driven

Samply available: 7~10days.

Qty: 1pc, only pump head is provided.

Price: US$100~200

OEM is welcome

OEM expierence: more than 10 years.

Countries: Germany, U.S.A, Spain, Italy, United Kingdom etc

Warranty: the whole pump is guaranteed within 1 year, the pump's spare parts are guranteed for 3 months from the date of delivery.

For more information, please do not hesitate to contact me.

The information should be including inquiry as following:

1.Pump's flow rate

2.Pump's Head (Pressure)

3.Driven Mode: By electric motor or diesel engine or bare shaft etc

4.Power and rotary speed

5.Suction lift for self priming pump

6.Temperature of liquid if you can provide

Upon the receipt of the pump's parameter, we can send our quotation to you within 24 hours.

Or the condition of pump station would be provided.

♦FAQ:

1. Q: Can I know more about your products?

A: Pls view our website: www.lanco.cc.

2. Q: What’s your MAQ of this item?

A: 1~2PCS

3. Q: What is the lead time?

A: 10~30 days after receiving your payment,depends on pumps.

4. Q: where is your loading port?

A: Ningbo, China port

5. Q: Are you a manufacturer or trading company

A: We are a manufacturer specialize in water pump and other pumps more than 20 years.

For more information, please contact me.

- Q: A residential building with a floor height of 11 stories and a roof height of 33 meters. The height of the water tank is 37.7 meters. The basement is -3.3 meters, only set fire hydrant, fire pump only consider the indoor fire water, fire flow should be 10l/s. Now select a fire pump, concrete should be much traffic, big head, flow determine how? How to determine the head, I hope to say some more detailed, thank you, and there is to explain this question, why is the fire pump lift 120?. Thank you

- According to the water quantity form fire flow water supply system fire safety in high-rise building fire hydrant pump lift is 10L/s, accurate algorithm is to say after a simple calculation with each indoor hydrant flow is two 5L/s bolt so to get the most unfavorable point for the calculation unit to calculate the minimum requirements, with the most unfavorable point suppository pressure specifications 0.07MPa, partial loss of the most unfavorable line and the line (according to the equivalent length) and loss (according to the material resistance coefficient), and finally the pump head loss of gravity difference. But we just calculate the construction elevation difference multiplied by 110% to 120% to determine the head {there is a need to know is: conversion head (m), (kg) and MPa kg 1MPa=10 kg = 100m is the vertical water column on unit area pressure conversion

- Q: Is the vacuum pump air compressor?

- A vacuum pump is a device or device that uses a mechanical, physical, chemical, or physical chemical method to pump a vacuum from a container to be evacuated. Generally speaking, a vacuum pump is a device that uses various methods to improve, produce, and maintain a vacuum in a confined space.

- Q: What are the basic technical parameters of the pump?

- Two, pump head H head is the unit weight of the liquid pump pumping from the inlet of the pump (pump inlet flange) to the outlet of the pump (pump outlet flange) energy value. Effective energy is a Newtonian liquid through the pump unit is obtained. The N m/N=m, the height of liquid column pumping liquid. Habits referred to as meters. Three, the pump speed is n RPM pump unit time revolutions, represented by the symbol n, the unit is r/min. four, the pump NPSH NPSH NPSH is also called net positive suction head, said main parameters of cavitation performance. Cavitation has been used a h power of five, the power of the pump. And the efficiency of the pump is usually refers to the input power, which is the prime mover on the pump shaft power, it is also known as the shaft power, denoted by P;

- Q: The main factors affecting the performance of centrifugal pumps

- Revolutions required to have. It has the following meanings: 1, similar to the geometry of centrifugal pump, everywhere efficiency at the top of the similar condition; centrifugal pump 2, than the number of different, its geometry must be different than the number; the same pump, its shape is similar, but does not rule out the shape similar situation. The following factors are related to specific speed. The specific speed of centrifugal pump has nothing to do with the nature of the conveying fluid, but has a close relationship with the shape of the impeller and the performance curve of the pump. The pump with high specific speed corresponds to the highest efficiency when the flow rate is large and the head is small

- Q: Is the sewage pump the same as the mud pump?

- Sewage pump is mainly used for industrial wastewater treatment, sewage treatment, environmental protection has played a big role. Among them, the sewage pump is also a sewage pump with cutting wheel, such sewage pump can be chopped dirt, and then extract the sewage clean.

- Q: How many pumps does the 80cm tank use?

- Mainly look at the flow of the pump, all pumps have flow signs, such as 15L/HThe above is I at random, meaning that 15 litres per hour. You should calculate the volume of your cylinder, that is, the length of the tank, the width and the height of the water surface, the unit is cm. The result is 1000, which is the volume of your fish tank

- Q: Is vane pump good or gear pump good?

- The main working parts of vane pump is provided with a plurality of sliding vane rotor, when the rotor rotates, the eccentric configuration of stator cavity contour or rotor, blade sliding slot in leaves due to volume changes, resulting in the suction effect. The similarities are: 1, rotary type positive displacement pump has self-priming ability, but are not allowed to do; 2, with continuous flow pulsation, but also have flow and pressure; 3, the theory of flow is determined by the working parts of the size and speed, has nothing to do with discharge pressure; 4, rated discharge size, pressure and working parts mainly depends on the pump speed is independent of the sealing parts and bearing capacity; differences: 1) gear pump structure is more simple, reliable, low price; vane pump has complicated structure and high manufacturing precision parts, the blade is easy to get stuck, more sensitive to the oil clean degree and viscosity.

- Q: Does the control cabinet of the fire control pump need to be related to the fire control room?

- Automatic sprinkler, which is mostly used in this device or high water tank, the whole set of equipment must meet the most unfavorable point (the farthest the highest point of water) water pressure of the faucet.

- Q: Metering pumps related matters

- Rotate to stroke length 100% position. This allows the kit to rotate to the back of the drain hole and align the bottom of the pump. Adjust the hydraulic end and diaphragm to the proper position during the pump operation.The duration of the pulse may not be long enough for the reaction time. With respect to the standard pulse width 80msec, the flow monitor pulse width expansion can be activated, increasing the pulse width to 300msec. Activate the smart switch, remove the cover fixed circuit board, remove the jumper X-1. This activates the extended function and allows more time before the failure instructions.Metering pump installed from the exhaust pump head, the use of self suction liquid imbibition. Keep the suction line as short as possible.

- Q: What is the distance between the pump and the wall?

- Mainly depends on the maintenance, installation is convenient, but there is no other requirements.

Send your message to us

Self priming 6 inch diesel water pump with trailer

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 4 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords