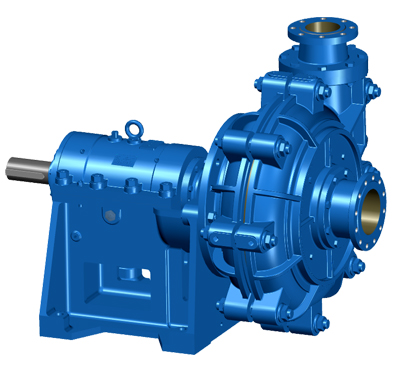

Slurry Pump for Mining Indurstry

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

ZS series slurry pump is developed to be of the advanced world level based on 40 years of pump manufacturing and abundant trash pump technology,fully analyzing its different field operation requirements for different industrial applications,introducing the most advanced design theory and collecting the trade talents at home and abroad.

The slurry pump is characterized by its high efficiency,rational structure,high reliability,easy maintenance and low operation cost.It is widely applied to transport slurry containing solid particles in coal,electric power,metallurgy,chemical industry,etc.The maximum volume density for the solid mixed liquids:Cv≤30%,and its weight density is Cw≤60%.The flow passage is wide,and its flow capacity is great.

Application Area

Mines:For the feeding of ferrous and non-ferrous ore pulp and transportation of various concentrate pulp and reject pulp etc.

Metallurgy:For the transportation of various slime in aluminum plant(containing high-temperature slime,≤106℃),and the transportation of various slurry in steel plant.

Coals:For coal exploitation and transportation of various coarse、fine coal slurry(middlings and cleaned coals,etc) for washing.

Electricity:For electrical plant removing ash or ash- flushing,and the transportation of various ashes、mortars,etc.

Construction materials:For the transportation of various sand slurry(For instance,cement mill slime),etc.

Chemical industry:For the transportation of various chemical abrasive and corrosive slime(For example:phosphate fertilizer,potash fertilizer and so on.)

Environmental protection:For stack gas desulfurization and transportation of varous abrasive and corrosive slime.

Hydraulic engineering:For the dredging of pools and waterway,and pumping of sand,grit and clays,etc.

Performance Range

Outlet diameter: DN=25~300mm

Capacity: Q=44~2200m3/h

Head: H=16~116m

Speed: n=490、590、740、980、1480r/min

Permissible series connection working pressure: 2MPa

Matched power:P=5.5-800kW

- Q: What is the name of the day pump and ground pump? Specific introduction

- People often say "day pump" actually refers to the boom pump, it also has many other name, such as pump, boom pump, concrete pump, concrete pump truck, these words are "day pump".Ground pump, in fact, refers to the pump drag pump. Therefore, to understand the difference between day pump and ground pump is to understand the difference between the boom pump and the tow pump

- Q: What is the dry running protector of screw pump? What's the principle and function? Thank you

- When the temperature reaches a certain value, the signal is transmitted to the electric control box through a dry running protector, and the electric control box is used to stop the screw pump so as to protect the screw pump.

- Q: What is cavitation, centrifugal pump cavitation phenomenon how to solve?

- The pump is in operation, if the over-current part of the local area (usually the impeller blade inlet somewhere later) for some reason, the absolute pressure of pumping the liquid was reduced to liquid vapor pressure temperature, liquid vaporization began in the area, produce a lot of steam, forming bubbles, when the liquid contains a lot of bubbles forward by high pressure impeller zone, high pressure liquid around the bubbles in the bubble decreases drastically and rupture. Condensation in the bubble burst at the same time, the liquid particle filled hole at a high speed, this moment has a very strong effect of water hammer, and with a high impact frequency against the metal surface, the impact stress of hundreds to thousands of atmospheric pressure, impact frequency can be up to tens of thousands of times per second, serious breakdown when the wall thickness will be.The process of cavitation in a pump is caused by the bursting of bubbles and bubbles in the water pump and the destruction of the over-current components. Water pump cavitation, in addition to the over-current components will have a destructive effect, but also noise and vibration, and lead to the performance of the pump down, seriously when the pump will be interrupted liquid, can not work properly.

- Q: Does vacuum pump oil belong to dangerous goods?

- Of flammable substances, but not included in dangerous goods!Does not belong to dangerous goods,

- Q: Why can't the inlet of centrifugal pump be negative pressure?

- Can be negative pressure ah, the negative pressure here refers to the pressure is less than the atmospheric pressure, but the pressure can not be too low, to prevent water vapor below the saturated vapor pressure, so that water vaporization, cavitation phenomenon, the centrifugal pump will be considered.

- Q: What's the difference between non negative pressure and variable frequency water pump?

- No negative pressure is superposed pressure intelligent frequency conversion equipment, pump frequency operation is no negative pressure difference, and the variable frequency pump, variable frequency pump is advanced municipal tap water tank or pool, pump from the tank or pond water pressure to set pressure to the pressure water supply, and no negative pressure directly from water the municipal pipeline, using the original municipal 2~3 kilograms of pressure

- Q: What are the characteristics of a vertical multistage centrifugal pump?

- A liquid that is primarily diluted, clean, non corrosive, explosive, or similar to water but contains no solid particles or fibers. Because of its high flow and large lift, it is widely used in fire fighting, water supply and air conditioning unit cooling water transportation in high-rise buildings.

- Q: What should be used to pay attention to the use of mechanical pumps?

- There are many kinds of pumps, such as centrifugal pumps, piston pumps, diaphragm pumps, vane pumps, gear pumps, etc.

- Q: What's the difference between a concrete pump and a concrete pump truck?

- Concrete pump is a pumping machine used in the field, while the concrete pump truck is a truck mounted pump.

- Q: What is the cause of the damage of pump bearings?

- Is the water pump motor overheating or damaged leaves overheating, resulting in overheating bearings, lubricating oil dry, excessive wear and tear guide system damage

Send your message to us

Slurry Pump for Mining Indurstry

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches