PLC Control Non-negative Pressure Water Supply Equipment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PLC Control Non-negative Pressure Water Supply Equipment

1.Structure of PLC Control Non-negative Pressure Water Supply Equipment Description

PLC Control Non-negative Pressure Water Supply Equipment is a high efficient water facility has characters of easy installation,saving space, water pool is not required.The pump energy efficient, using I mm converter speed control valve control over a large number of energy saving, the elimination of the high level of secondary pollution of water tanks,water tank eliminates the need to wash the cost and trouble,Water Pump achieve soft-start, start on the grid to reduce the impact of pumps to extend life.

2.Main Features of the PLC Control Non-negative Pressure Water Supply Equipment

Water Supply: Urban water supply, boiler or condensate system, water filtering and distribution, water to water district, in charge of pressurized, high-rise building pressurization.

Industrial boosting: process water system, cleaning system, high pressure washing system, fire system.

Industrial liquid conveying: cooling and air conditioning systems, boiler feed and condensate systems, machine matching, acid and alkali.

Water Treatment: Industrial circulating system and processing system, environmental protection water treatment and infiltration analysis system, Ultrafiltration systems, reverse osmosis systems, distillation systems, separators, swimming pool

Irrigation: Agriculture irrigation and dewatering, sprinkler irrigation, drip irrigation.

3.PLC Control Non-negative Pressure Water Supply Equipment images

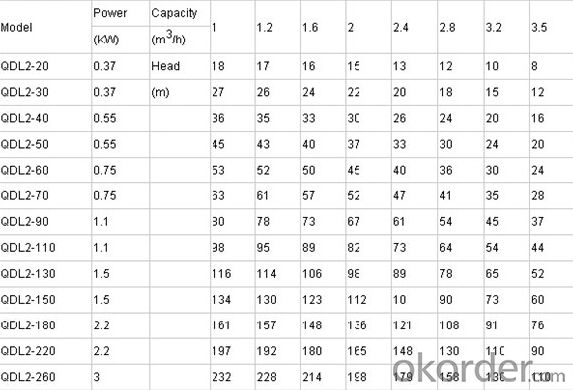

4.PLC Control Non-negative Pressure Water Supply Equipment Specification

5.FAQ

① What is your product range?

Centrifugal pump, slurry pump, gravel pump, clean water pump, sewage pump, chemical pump, single stage

pump, double suction pump, industry pump, oil pump, paper pulp pump, mud pump, self-priming pump, pipe

water pump, boiler water pump, etc.

② Are you a manufacturer?

Yes, we have been in manufacturing and marketing industry centrifugal pump over 20 years.

③ What information should I let you know if I want to get a quotation?

Pump capacity, pump head, medium, medium temperature, pump material, quantity, if possible, please also

provide the pump model you are using now, price will be calculated as per the pump model, if not, we willrecommend relevant product for reference.

- Q:What are the characteristics of the piston pump?

- Piston pump is an important device of hydraulic system. It depends on the plunger in the cylinder in reciprocating movement, so that the volume of the sealing chamber volume changes to achieve oil absorption and oil pressure. Plunger pump with a rated pressure, compact structure, high efficiency and flow and easy adjustment, is widely used in high pressure and large flow and flow needs to adjust the occasion, such as hydraulic machine, engineering machinery and ships.

- Q:If the calculation of the required pump flow is 45, lift 110, and the actual pump flow 100, head 125, what will happen in operation? Can I use it properly?

- The air pump.The pump itself is mechanical failure.The pump outlet valve core off.Low voltage power.

- Q:There are second cutting, third cutting, why three times?

- So some pumps are written in the back of XXXX-125A or B, that is, the impeller nominal diameter is 125, A is through a cut, B is the 2 cutting. To reach the applicable conditions, only the calculation is not enough, but also after cutting to test to determine.

- Q:What is the series of pumps? What is the difference between a unipolar and a multilevel? What is the meaning of each "first class"?

- A single-stage pump is a pump with only one impeller. 2, a multistage pump is a pump with two or more impellers. The multistage pump can increase the pressure and lift the head higher. Level 1 means a booster impeller.

- Q:Operating procedures for measuring pumps

- start-up1. Adjust the stroke indication to zero by adjusting the nut or handle with the rotary stroke.2 open the outlet valve.3. Open the inlet valve, pump, exhaust from the high point, exhaust from the relief valve, the breather valve.4, point motor, check the operation of the pump.5. Start the motor.6, without pressure on the premise, every 15 minutes to improve the stroke 20%, if there is no pressure, do not substantially improve the stroke.Note: (1) whether the sound or vibration of the pump is abnormal (2), whether the stroke adjustment is automatic or not

- Q:Roots pump and dry pumpRecently involved in the work of the vacuum pump, don't understand this, is a ads602 vacuum pump, composed of roots pump and dry pump, is pre pumped to the 500mtorr equipment, the main pumping vacuum continues to 10mtorr, where the roots pump and dry pumps must be used? What role they play respectively. The so-called dry pump? Is refers to one kind of the pump, the pump is many dry pump? Also do not understand how the work of automatic switching system for pre pumping, the main pump, pump work alone did not connect system ah (of course there are even a butterfly) teach?

- Here the roots pump and dry pump must be used, because the roots pump is not used alone, and must be a stage vacuum pump (pre vacuum pump can be dry pump, water ring vacuum pump and rotary vane vacuum pump can be, you here with dry pump series)

- Q:Water pump does not produce water, what are the reasons?

- 4. as a water inlet valve, check whether it is normal, whether the silted up.5. the installation height of water pump exceeds the allowable suction height of pump, or the suction pipe is too long.

- Q:What are the problems that should be paid attention to when using vacuum pumps?

- (8) in the process of running the pump, the bearing temperature shall not exceed the ambient temperature 35C, and the maximum temperature shall not exceed 80C.(9) if the abnormal sound of the vacuum pump is found, the reason should be stopped immediately.(10) vacuum pump to stop using, first shut down valve, pressure gauge, and then stop the motor. (11) vacuum pump in the first month of work, 100 hours after the replacement of lubricating oil, oil every 500 hours after the change.(12) adjust packing gland regularly to ensure the normal condition of drip in packing room. (13) regular inspection of shaft sleeve wear, larger wear should be replaced in good time.

- Q:What does "dual purpose" of water pump mean? Please expert advice

- In order to ensure safe and continuous operation, three pumps usually need two units and run one standby.Precautions for using pumps1, if there is any small water pump failure, remember not to work. If the pump shaft packing end wear should be added in time, if you continue to use the water pump will leak. The direct effect of this is the increased energy consumption of the motor, which will damage the impeller.

- Q:What is the difference between centrifugal pump and positive displacement pump?

- The centrifugal pump is to rely on high-speed rotation of the impeller to do work on the fluid. These two types of pumps are also the most widely used.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PLC Control Non-negative Pressure Water Supply Equipment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords