Colored borosilicate glass tube for Mouth blowing glasswares

- Loading Port:

- XINGANG

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 20000000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Description:

Using the latest technology, our coloured borosilicate glass tubing3.3 correspond to the internationally acknowledged borosilicate glass type 3.3(DIN ISO 3585).

All stages of production are strictly controlled and backed up by a complete quality control system according to ISO9002.

Till now we can supply eleven kind of colors: transparent black borosil glass tubing, teal borosilicate glass tubing, dark blue borosilicate glass tubing, dark amber borosilicate glass tubing, pink borosilicate glass tubing, opaque black borosilicate glass tubing, yellow borosilicate glass tubing, red borosilicate glass tubing, green borosilicate glass tubing etc

2. Technical Description

Regular Specification: 25*4mm, 32*3.2mm, 32*4mm, 38*3.2mm, 38*4.0mm, 44*4.0mm, 51*4.0mm, 51*4.8mm etc.

Color high borosilicate glass is a kind of hard glass, Coefficient of thermal expansion is 3.30.1*10-6/K.

It is a kind of special glass material which is low inflation, high temperature resistant, high strength, high hardness, high light transmittance and high chemical stability. Because of its molecular structure is more closely, so even very thin is still strong and durable, The glass is colored at temperatures above 1600 degrees, so color is bright such as crystal clear, the color is never changed. In the production process, the technician keeps spinning the embryo and pulling it into a grain written. So observed in the sun, there are some textures, this is the normal glass process phenomenon.

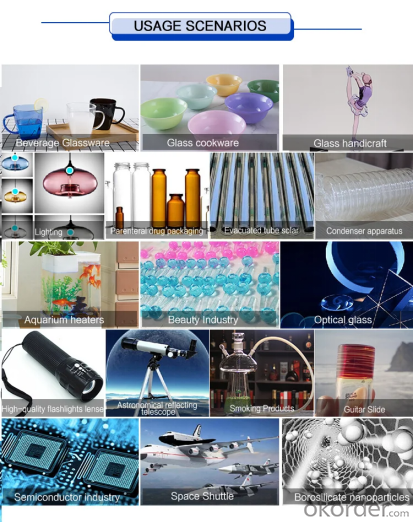

3. Widely usages of borosilicate glass tube

1. Kitchenware

2. Lighting Decorations

3. Chemical equipment

4. Solar Vaccum Tubes

5. Glass Arts & Crafts

6. Glass Smoking Pipes

7. Medical Pacakaging

8. Laboratory Instruments

4. Advantages

1. High quality,competitive price and elegant appearance

2. Accurate dimension according to customs' request

3. Long time to use

Customize specifications according to your demands:

O. D from 4mm~315mm,

W.T from 0.8mm~9mm,

5. Business Terms

Delivery time: Within 20days after received the advance payment.

Payment: 30%-50% TT in advance and balance against copy of BL.

Transport: By ship or express

Colors available: opaque black, opaque white, pink,purple, green,yellow, amber,dark blue, light blue, transparent blac

Usage:

6.

Process:

7. Packing and Shipping:

All the glass will pack in cartons, and load in container strong firmly, to make sure safety delivery.

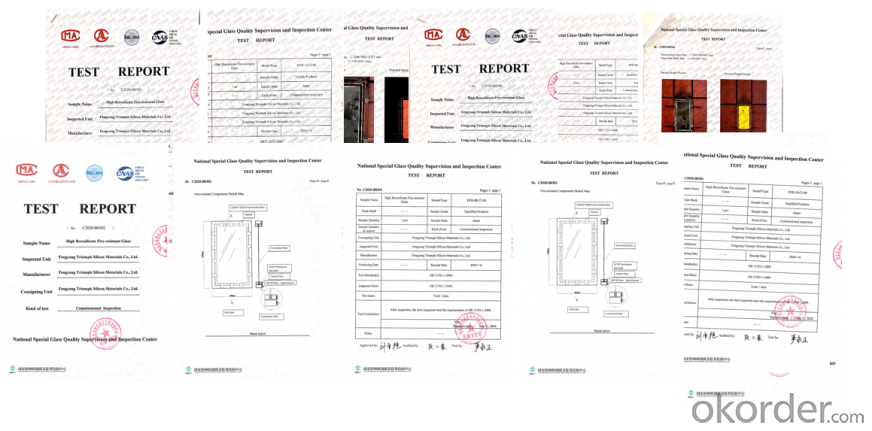

8. Test Report

9. Company Brief:

10. FAQ:

Q1: Are you factory or trading company?

A: We are manufacturer in Hebei Province near Beijing,and we also have trading office in Beijing.

Q2: Can support OEM&ODM order?

A: Yes,we have rich experience in OEM&ODM production, can meet your personalized needs.

Q4: Can you do the designs for us?

A: Yes.We have a professional team having much experience in designing and manufacturing.Just let us know your ideas,we will draw the finished files for your confirmation.

Q5: What format of the file do you need if I want my own design?

A: You can provide JPG,Al,or PDF etc,Our professional designer will draw art work for mould or printing screen for you.

Q6: How can I get some samples?

A: Sure,we usually provide existing samples for free.But a little sample charge for custom designs,Sample charge is refundable when order is up to certain quantity.

- Q: Renovation of the house to buy bricks when how to see the quality of good or bad? What kind of good?

- Glazed tile of this tile is made of tile bottom and surface of a layer of glazed, that is, in the ceramic embryo on the glaze, after high temperature and high pressure firing, ceramic tile glaze is mainly to increase the beauty of the role of ceramic. Glazed tiles are divided into floor tiles and wall tiles according to the place of use.

- Q: Is the balance pad the raw material in the motor?

- Its main function is the use of mechanical energy into electrical energy, the most common is the use of thermal energy, water power, and so on to promote the generator rotor to generate electricity.

- Q: Comparison of plexiglass steel bridge and inorganic glass steel bridge

- Organic glass fiber reinforced plastics and inorganic glass fiber reinforced plastic properties of one, plexiglass resin (referred to as resin) advantages: 1, good toughness; 2, high strength; 3, waterproof performance is good; 4, light weight. (the weight of inorganic glass of the same size is about 1.2 times of that of plexiglass) and the disadvantages of organic glass fiber reinforced plastics: 1. Not high temperature resistant. (in general, the temperature is 70 degrees Celsius, it has begun to deform) 2, no aging resistance. (affected by ultraviolet light, easy to deformation, fade) 3, easy to burn.

- Q: What material does PCB have?

- The surface of the substrate is covered with a layer of high conductivity, good welding of pure copper foil, commonly used thickness of 35 ~ 50 / Ma; copper foil covered in copper clad laminate substrate side called single copper, copper clad laminate substrate on both sides covered with copper foil called double-sided copper clad laminate; copper foil can securely covered on the substrate. The adhesive to complete. Commonly used CCL thickness of 1.0mm, 1.5mm and 2.0mm three.

- Q: Medium temperature glass flake clay products

- Glass scales prevent the erosion of base material by water vapor and chemical solvents. The degree of chemical resistance of the substrate or coating varies with the chosen glass material, and the glass scale, which is made of c- glass, has excellent chemical durability.

- Q: Which brand of thermos cup is safe, double glass is not really glass, there is no other add, affect health?

- Stainless steel material specifications, which 18/8 said that the stainless steel material composition containing 18% chromium, containing 8% nickel, reached the standard materials, in line with the national food standards is the green environmental protection product, rust and corrosion products. Ordinary stainless steel cup body color is pale and dark, if the brine into the concentration of 1% will produce rust after 24 hours, which contains some elements exceed the standard, the direct harm to human health.

- Q: What are the materials for car windshields? Is there anything different than ordinary glass?

- Prospects: glass technology has now completely penetrated the automotive industry, becoming an indispensable part of the automotive technology field. Although China is still the automotive industry such as glass and glass industry (BSG) belong to two different areas of the industry, the former belongs to the machinery manufacturing industry, which belongs to the light industry, but from the development of the car, the relationship between the two is more and more close. Nowadays, people always study and develop automotive glass from the perspective of automobile safety and appearance, and introduce new varieties.

- Q: What are the raw materials for producing edible glass bottles (such as pickles bottles, fermented beancurd bottles, etc.), and glass is the kind of glass material?

- To the Chinese packaging bottle net glass bottle information, take a look at it, are glass bottle production technology and so on related articles, the only domestic bottle site.

- Q: How is glass made, raw material proportioning?

- The manufacturing technology of the use of glass a thousand li a day, increasing by the clock, glass, doors and windows, lamps, such as high-tech electronic components and space technology, are indispensable glass. Our daily contact with most of the "flat glass is" thick to thin for doors and windows, clocks and the use of medical tests, the manufacturing method is that the furnace in the glass slurry level or traction method (also called float) and vertical traction method. After the dissolution of soluble traction after furnace also has the cooling system, cooling after the completion into a "flat glass, flat glass thickness mainly depends on the speed of traction, traction faster, can be manufactured and thinner. Although the ordinary flat glass from the front appears bright transparent, but from the side near the edge is slightly blue, because the amount of glass color depends on the main raw material in the manufacture of glass - quartz sand and iron content of purity. Generally, the thin glass used in the watch industry is superior in quality but expensive in value, mainly because the material used in quartz sand is superior and the iron content is very low (usually under 3/10000)

- Q: What raw material is the front bumper of the car made of?

- Tempered glass (Tempered, glass/Reinforced, glass) belongs to safety glass.

Send your message to us

Colored borosilicate glass tube for Mouth blowing glasswares

- Loading Port:

- XINGANG

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 20000000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches