Tinplate and Raw Metals for Tin Plate Scrap South Africa with Competitve Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Tinplate and Raw Metals for Tin Plate Scrap South Africa with Competitve Price Description

| Steel Type | MR | ||

| Temper(BA&CA) | T1~T5, DR8, DR9 | ||

| Coating | 1.1~11.2g/m2 (Both Equal and Differential) | ||

| Thickness and tolerance | 0.15~0.50mm(Tolerance: _+0.01 mm) | ||

| Width & tolerance | 300~1000mm (Tolerance: 0~3mm) | ||

| Cut length & tolerance | 450~``50mm (Tolerance: 0~3mm ) | ||

| Coil inside diameter | 420/508mm | ||

| Coil Weight | 3~10 MT | ||

| Passivation | 311 | ||

| Oiling | DOS | ||

| Surface Finish | Bright, Stone, Silver, Matte | ||

| Packaging | Seaworthy Standard with wooden pallet | ||

| Standards Available | GB/T2520, JIS G3303, ASTM A623M & EN10202 | ||

| Special specitications are available on request. | |||

Tinplate and Raw Metals for Tin Plate Scrap South Africa with Competitve Price China

Tinplate can ensure food hygiene and minimize the possibility of corruption, effectively

prevent the danger to health, but also in line with modern convenience in tinplate packaging

of canned food diet, rapid demand, tea packaging, coffee packaging, health careproduct

packaging, candy wrappers, cigarette packaging, gift packaging, food packaging containers

are preferred.As well as other miscellaneous cans of the oils and fats cans, chemicals

cans, beverage cans, spray cans, and and so on on.

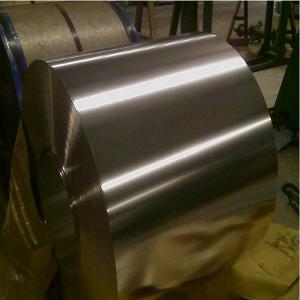

Tinplate and Raw Metals for Tin Plate Scrap South Africa with Competitve Price Images

Tinplate and Raw Metals for Tin Plate Scrap South Africa with Competitve Price Specification

FAQ of Tinplate and Raw Metals for Tin Plate Scrap South Africa with Competitve Price

How long does it take to get the product if i place an order?

With the process of your requirements,we will pack and deliver in 3-7 days.If it is by sea shipment,it will take 15-45 days depending on different locations.

- Q: What are the challenges in manufacturing tinplate?

- One of the main challenges in manufacturing tinplate is the complexity of the production process. It involves several steps such as shaping, coating, and annealing, which require precise control and coordination. Additionally, maintaining the quality of the tin coating can be challenging as it needs to adhere uniformly to the steel substrate without any defects. Furthermore, ensuring the tinplate's durability and resistance to corrosion is crucial, requiring continuous monitoring and testing. Overall, managing the intricate manufacturing process, achieving consistent quality, and meeting customer demands pose significant challenges in tinplate production.

- Q: What are the typical dimensions of tinplate sheets?

- The typical dimensions of tinplate sheets can vary, but they are commonly available in sizes ranging from 0.15mm to 0.35mm in thickness, with widths of 600mm to 1200mm, and lengths ranging from 800mm to 2400mm.

- Q: What are the main regulations governing tinplate production?

- The main regulations governing tinplate production vary by country and region. However, some key regulations typically include guidelines on the use of materials, such as the type and thickness of tin coatings, as well as regulations on production processes to ensure safety and quality standards are met. These regulations may also cover areas such as labeling, packaging, and transportation requirements to ensure proper handling and traceability of tinplate products.

- Q: Can tinplate be used for construction materials?

- Yes, tinplate can be used for construction materials. Tinplate is a type of steel coated with a layer of tin, which provides it with corrosion resistance and durability. It is commonly used for manufacturing various construction components, such as roofing materials, wall claddings, and structural elements. Its strength, versatility, and aesthetic appeal make it a suitable choice for construction applications.

- Q: Can tinplate packaging be used for clothing accessories?

- Yes, tinplate packaging can be used for clothing accessories. It is a durable and versatile material that can be shaped into various forms, making it suitable for packaging small items like jewelry, belts, or hair accessories. Additionally, tinplate packaging offers a unique and visually appealing option for displaying and protecting clothing accessories.

- Q: How does tinplate contribute to the preservation of paint products?

- Tinplate contributes to the preservation of paint products by providing a durable and protective packaging solution. It is a corrosion-resistant material that prevents the paint from coming into contact with oxygen, moisture, and other external factors that can lead to degradation or spoilage. Additionally, tinplate cans are known for their tight seals, preventing any leakage or contamination that could compromise the quality and longevity of the paint inside.

- Q: What are the main factors affecting tinplate coil loading and unloading?

- The main factors affecting tinplate coil loading and unloading include the size and weight of the coils, the type and condition of the loading and unloading equipment, the skill and experience of the operators, and the safety precautions in place. Additionally, factors such as the layout of the loading and unloading area, weather conditions, and any specific requirements or regulations for handling tinplate coils may also impact the process.

- Q: How does tinplate handle extreme weather conditions?

- Tinplate is known for its excellent resistance to extreme weather conditions. It is highly durable and can withstand harsh temperatures, humidity, and exposure to sunlight without significant degradation. Its protective coating prevents rusting and corrosion, making it a reliable choice for outdoor applications.

- Q: How does tinplate packaging contribute to product aesthetics?

- Tinplate packaging contributes to product aesthetics by offering a visually appealing and versatile option for packaging. Its shiny and reflective surface adds a premium and luxurious look to products, enhancing their overall aesthetic appeal. Additionally, tinplate packaging can be easily customized through various printing techniques, enabling brands to create eye-catching designs, logos, and graphics that attract consumers' attention on store shelves. Its durability and ability to maintain color and shape also ensure that the product's aesthetic appeal remains intact throughout its lifespan.

- Q: How can the section of the tinplate be maintained without rust?

- Unless there is a way to seal it, keep it out of contact with the air, and prevent oxidation, there is no other way.

Send your message to us

Tinplate and Raw Metals for Tin Plate Scrap South Africa with Competitve Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords