Tinplate for Chemical Packaging with Competive Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

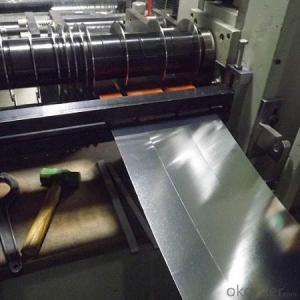

Tinplate for Food Pakcaging and Chemical Packaging

Specifications

Prime electrical tinplate:

Thickness: 0.15 to 0.50mm

Width: 600 to 1010mm

Temper grade: BA and CA

For metal packaging usage

The Tinplate specification as following:

1, Reference standard: GB2520-88, JIS G3303-1997 and DIN EN10203-91

2, Material: MR, SPCC

3, Thickness available: 0.15mm to 0.50mm

4, Width available: 600mm to 1010 mm

5, Temper grade: T1 - T5 BA and CA both.

6, Tin coating: ordinary 2.8g/2.8g, 5.6g/5.6g, We also can produce according to customers' requests

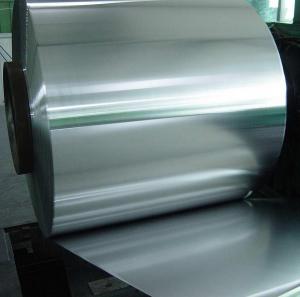

7,Coil diameter: ID 420/ 508mm, OD from 1,000 to 1,250mm

8,Package: Anti-rust paper,corner protected. by sheet or coils according customer's require.

9, Applications: metal package usage like paint, chemical can,aerosol can and different food can production,

Also battery,electric cable and other industries

| Tinplate specifications | |||

| Steel Type | SPCC, MR | ||

| Temper(BA&CA) | T1~T5 | ||

| Coating | 1.1~11.2g/m2 | ||

| Thickness and tolerance | 0.15~0.50mm(Tolerance: _+0.01 mm) | ||

| Width & tolerance | 300~1000mm (Tolerance: 0~3mm) | ||

| Cut length & tolerance | 450~``50mm (Tolerance: 0~3mm ) | ||

| Coil inside diameter | 420/508mm | ||

| Coil Weight | 3~10 MT | ||

| Passivation | 311 | ||

| Oiling | DOS | ||

| Surface Finish | Bright, Stone, Silver, Matte | ||

| Packaging | Seaworthy Standard with wooden pallet | ||

| Standards Available | GB/T2520, JIS G3303, ASTM A623M & EN10202 | ||

| Special specitications are available on request. | |||

| Tin coating weight | |||

| Type | Designation of tin coating weight | Min.average tin coating weight(g/m2) | Former Coating Designation |

| Equal tin coating | 1.4/1.4 | 1.2/1.2 | #15 |

| 2.2/2.2 | 2.0/2.0 | #20 | |

| 2.8/2.8 | 2.45/2.45 | #25 | |

| 5.6/5.6 | 5.05/5.05 | #50 | |

| 8.4/8.4 | 7.55/7.55 | #75 | |

| 11.2/11.2 | 10.1/10.1 | #100 | |

| Differentially Coating | 1.4/2.8 | 1.2/2.45 | #15/25 |

| 2.2/2.8 | 2.2/2.45 | #20/25 | |

| 2.8/5.6 | 2.45/5.05 | #25/50 | |

| 2.8/8.4 | 2.45/7.55 | #25/75 | |

| 2.8/11.2 | 2.45/10.1 | #25/100 | |

| 5.6/8.4 | 5.05/7.55 | #50/75 | |

| 5.6/11.2 | 5.05/10.1 | #50/100 | |

| 8.4/11.2 | 7.55/10.1 | #75/100 | |

| Surface finish | |||

| Surface finish | Nominal surface roughness (um Ra) | Characteristic | |

| Bright finish | ≤Q0.35 | Glazed surface obtained after melting treatment of electrotinned smooth raw materail strip with extremely fine rubstone fingure by processing. | |

| Stone finish | 0.25~0.60 | Glazed surface obtained after melting treatment of electrotinned smooth raw materail stripfeaturing certain rubstone figures. | |

| Silver finish | 0.50~1.00 | Glazed surface obtained after melting treatment of electrotinned smooth raw material strip with rough matt furface. | |

| Matte finish | 0.80~2.50 | Matt surface of general matt raw material strip without melting treatment. | |

- Q: What are the different methods of joining tinplate components together?

- There are several methods of joining tinplate components together, including soldering, spot welding, adhesive bonding, and mechanical fastening. Each method has its own advantages and suitability depending on the specific application and desired outcome.

- Q: How does tinplate contribute to the overall portability of packaging?

- Tinplate contributes to the overall portability of packaging due to its lightweight yet durable nature, making it easy to transport and handle. Additionally, its excellent resistance to corrosion and ability to preserve the quality of the packaged product ensures that packaging remains intact during transportation, further enhancing its portability.

- Q: How does tinplate handle exposure to pressure and impact?

- Tinplate is known for its excellent handling of pressure and impact. Its sturdy and durable nature allows it to withstand high levels of pressure without deforming or breaking easily. Similarly, it demonstrates remarkable resistance to impact, making it suitable for various applications that involve handling, shipping, or storage of goods.

- Q: Can tinplate be used for storage containers?

- Yes, tinplate can be used for storage containers. It is a common material choice due to its durability, corrosion resistance, and ability to keep food and other items protected. Tinplate containers are commonly used for packaging and storing various products, including food, beverages, chemicals, and more.

- Q: What are the weight advantages of using tinplate?

- Tinplate offers several weight advantages compared to other packaging materials. Firstly, it is significantly lighter than materials like glass or aluminum, making it easier to handle and transport. This lightweight nature also contributes to lower shipping costs. Additionally, tinplate's lightness allows for more product to be packaged in a smaller space, maximizing efficiency and reducing storage requirements. Overall, the weight advantages of tinplate make it a preferred choice for many industries seeking cost-effective and efficient packaging solutions.

- Q: Are there any specific regulations for tinplate in different countries?

- Yes, there are specific regulations for tinplate in different countries. These regulations vary from country to country and may include standards for the composition, quality, labeling, and safety of tinplate products. These regulations are in place to ensure consumer protection and product quality control.

- Q: How does tinplate perform in terms of insulation properties?

- Tinplate is not known for its insulation properties as it is a highly conductive material.

- Q: Is tinplate affected by moisture or humidity?

- Yes, tinplate is affected by moisture or humidity. Tinplate is a thin sheet of steel coated with a layer of tin, which provides corrosion resistance. However, prolonged exposure to moisture or high humidity can cause the tin layer to react with the steel, leading to corrosion and degradation of the tinplate's properties. It is important to store and handle tinplate in conditions that minimize exposure to moisture and humidity to maintain its integrity.

- Q: How does tinplate impact the ease of opening and closing packaging?

- Tinplate has a positive impact on the ease of opening and closing packaging. Due to its durability and strength, tinplate provides a sturdy and reliable structure for packaging materials. This makes it easier to open and close packaging without the risk of tearing or damaging the container. Additionally, tinplate often includes features such as easy-to-use lids or pull tabs, further enhancing the convenience of accessing the contents.

- Q: How is tinplate affected by extreme temperatures?

- Tinplate is generally resistant to extreme temperatures and can withstand both high and low temperatures without significant changes in its properties.

Send your message to us

Tinplate for Chemical Packaging with Competive Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords