Tinplate for making cans with competitive price

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

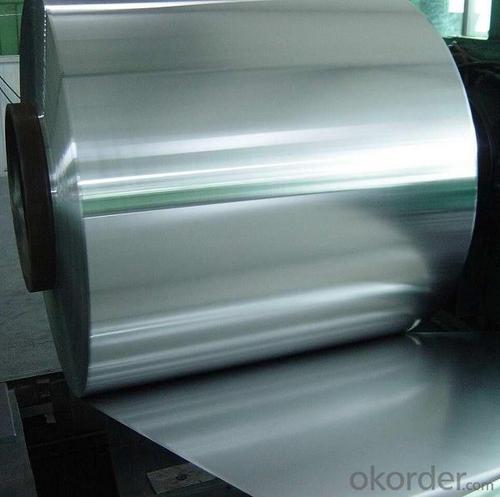

Tinplate for making cans with competitive price

1.Structure of Description

Electrolytic Tinplate Sheets is one of the metal packing materials, which is widely used for making painting cans ,chemical package cans , electrical cable ,battery and metal printing etc. For caps, there are some customers also need TFS, if you have some demand for TFS,also can contact with us.

2. Main Features

Steady and high quality

Fast shipment

Good experience for export work

For the surface, Plate uniform in thickness,uniform and smooth tin coating, without flaws,rusts,scratch,wave,nick of tin coating etc.

Specifications

| Type | MR, SPCC |

| Temper(BA&CA) | T1-T5, DR8-DR10 |

| Coating | 1.1-8.4g/m^2 |

| Thickness& Tolerance | 0.15-0.5mm(tolerance +/-0.01mm) |

| Width& Tolerance | 600-1010mm(tolerance +2/-0mm) |

| I.D | 508mm |

| Coil weight | 3-10MT |

| Passivation | 311 |

| Oiling | DOS |

| Surface finish | Bright, stone |

| Package | Seaworthy Export Standard Wooden Pallet |

| Standard | ISO 11949 -1995, JIS G3303,ASTM A623, BS EN 10202 |

| Special specifications are available on customers' requirements | |

FAQ

1. What is your tinplate used for?

Tinplate is widely used for making all types of containers, electrical machinery parts and many other products.

- Chemicals and painting cans

- Dry food cans, such as fancy cans, biscuit cans, milk powder cans, tea cans,

- Sea food cans

- Crown corks, easy open ends

- Electrical machinery parts

- Bakeware and household kitchen parts

2. What is your annual capacity?

Our annual capacity is 400,000MT

3. How many companies and factories in your group?

There are over 300 subordinate companies and factories in our group.

- Q: What are the regulations regarding tinplate packaging?

- Tinplate packaging is subject to various regulations, depending on the country and specific product being packaged. These regulations typically cover aspects such as food safety, labeling requirements, and environmental considerations. For example, in the United States, the Food and Drug Administration (FDA) regulates tinplate packaging for food products, ensuring they meet safety standards and are properly labeled. Additionally, there may be specific regulations related to recycling or disposal of tinplate packaging to minimize its impact on the environment. It is essential for businesses to research and comply with the relevant regulations to ensure their tinplate packaging meets all necessary requirements.

- Q: How does tinplate contribute to the safety and integrity of packaged products?

- Tinplate contributes to the safety and integrity of packaged products by providing a protective barrier against external factors such as moisture, light, and oxygen. This helps to prevent the deterioration and contamination of the packaged goods, ensuring their quality and extending their shelf life. Additionally, tinplate is a durable and sturdy material that offers excellent resistance to impact and mechanical damage, safeguarding the contents during transportation and handling.

- Q: How does tinplate contribute to the reduction of food waste?

- Tinplate contributes to the reduction of food waste by providing a protective and durable packaging solution for various food products. Its corrosion-resistant properties ensure the longevity of the packaging, preventing spoilage and contamination. Additionally, tinplate's ability to maintain the freshness and quality of food for an extended period helps reduce waste caused by premature expiration.

- Q: How does tinplate packaging contribute to product protection against contamination?

- Tinplate packaging contributes to product protection against contamination by providing a durable and secure barrier between the product and external elements. The tin coating on the steel substrate prevents corrosion and rusting, ensuring the integrity of the packaging. This protects the product from moisture, oxygen, and other contaminants that could compromise its quality or safety. Additionally, tinplate packaging is airtight, preventing the entry of bacteria or microorganisms, further enhancing product protection against contamination.

- Q: What are the advantages of using tinplate for electrical enclosures?

- There are several advantages of using tinplate for electrical enclosures. Firstly, tinplate is highly resistant to corrosion, making it ideal for protecting electrical components from moisture and other environmental factors. Additionally, tinplate is a strong and durable material, providing excellent protection against physical damage and impacts. Furthermore, tinplate is easily formable and can be shaped into various enclosure designs, allowing for flexibility in design and customization. Lastly, tinplate is a cost-effective option compared to other materials, making it a practical choice for electrical enclosures.

- Q: How is tinplate recycled?

- Tinplate is recycled through a process called steel recycling. The tin coating on the tinplate is first removed, usually through an acid bath. Then, the steel base is separated from the tin coating. The steel is melted down and used to make new steel products, while the tin coating can be reused for various applications, such as producing new tinplate or other tin-based products.

- Q: Can tinplate be used for packaging of perishable goods?

- No, tinplate is not suitable for packaging perishable goods as it is not airtight and does not provide sufficient barrier properties to prevent spoilage or contamination.

- Q: Tin can weldingHow can the side of the column of the pop top be welded or pressed?,

- The iron material thickness uniformity in the welding process, welding voltage and high requirement of control, the slightest mistake will cause breakdown or welding point is easy to fall off. As for the production of specific steps, personal suggestions to the scene you see, because the whole process is relatively simple, and when it comes to the production process and principle very boring, tedious. So, if you just want a rough understanding, there is no need for this.

- Q: What are the safety considerations when handling tinplate?

- When handling tinplate, it is important to consider several safety precautions. Firstly, tinplate can have sharp edges, so it is essential to wear protective gloves to prevent cuts or injuries. Additionally, tinplate may contain sharp metal burrs that can cause cuts or punctures. Therefore, it is advisable to handle the material carefully and avoid dragging or sliding it across surfaces. Furthermore, tinplate is susceptible to rusting, so it should be stored in a dry environment to prevent corrosion. Lastly, tinplate can be heavy, so proper lifting techniques should be employed to avoid strains or back injuries.

- Q: How does tinplate handle extreme weather conditions?

- Tinplate is highly resistant to extreme weather conditions due to its durable and corrosion-resistant nature. It can withstand high temperatures, heavy rain, snow, and intense sunlight without warping or deteriorating. Hence, it is an excellent choice for various outdoor applications, including roofing, construction, and packaging, providing long-lasting protection even in harsh weather conditions.

Send your message to us

Tinplate for making cans with competitive price

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords