Tinplate Packaging Market

Tinplate Packaging Market Related Searches

Tinplate Market Tinplate Packaging Tinplate Food Packaging Tinplate Stock Price Tinplate Share Price Tinplate Price Tinplate Production Tinplate Share Price Today Tinplate Price Per Ton Tinplate Share Price Nse Tinplate Price Trend Tinplate Share Price Bse Price Of Tinplate Tinplate Manufacturers Tinplate Material Define Tinplate Tinplate Shortage Tinplate China Tinplate Products Tinplate Company Tinplate Printing Tinplate Recycling Tinplate Suppliers Tinplate Coating Buy Tinplate Tinplate Products Ltd Tinplate Uk Tinplate Future Tinplate Factory Tinplate BoxTinplate Packaging Market Supplier & Manufacturer from China

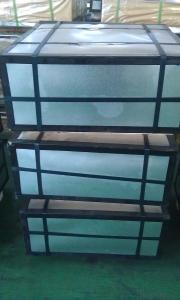

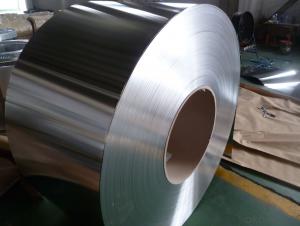

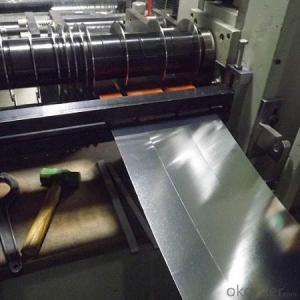

Tinplate packaging market encompasses a variety of products, including food cans, beverage cans, aerosol cans, and other metal containers. These products are widely used in the packaging industry due to their durability, recyclability, and barrier properties, which help preserve the freshness and quality of the contents. They are particularly popular in the food and beverage sectors, where maintaining the integrity of the product is crucial.Tinplate packaging is utilized in numerous applications and usage scenarios, such as preserving perishable goods, extending shelf life, and ensuring safe transportation of products. It is also favored for its ability to maintain the taste and aroma of the packaged items, making it an ideal choice for a wide range of consumer products. The versatility of tinplate packaging makes it a popular choice for various industries, from cosmetics to pharmaceuticals.

Okorder.com is a prominent wholesale supplier of tinplate packaging products, boasting a large inventory to cater to the diverse needs of its customers. The company is committed to providing high-quality tinplate packaging solutions at competitive prices, ensuring that businesses can access the materials they need to package their products effectively and efficiently. Tinplate Packaging Market is thus well-served by Okorder.com, which offers a comprehensive range of options to meet the specific requirements of different industries.

Hot Products