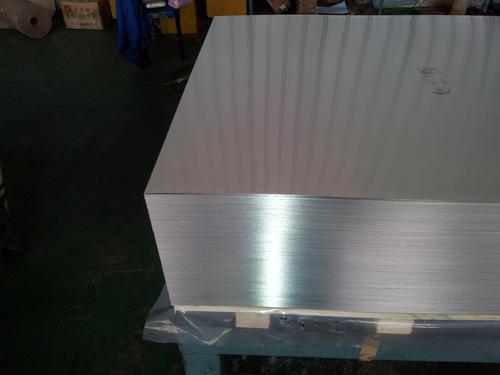

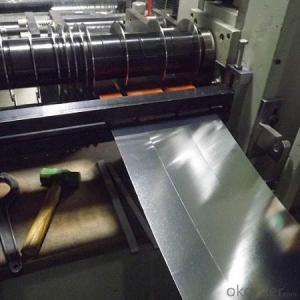

Prime Quality Tinplate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Our Tinplates Specification is as below:

Standard: ISO 11949 -1995, JIS G3303,ASTM A623, BS EN 10202

Material: MR,SPCC

Thickness:0.15mm - 0.50mm

Width and Length: 600mm -1150mm

Temper: T1-T5

Annealing: BA & CA

Tincoating:customized

- Q: How does tinplate affect the recyclability of mixed-material packaging?

- Tinplate plays a significant role in enhancing the recyclability of mixed-material packaging. It is highly recyclable and has a well-established recycling infrastructure worldwide. By incorporating tinplate into mixed-material packaging, it enables easier separation of different materials during the recycling process. Tinplate's recyclability helps reduce waste and conserve resources by enabling the recovery and reuse of valuable materials, ultimately promoting a more sustainable packaging system.

- Q: What are the different types of tinplate edge finishes?

- There are three main types of tinplate edge finishes: single edge, double edge, and scroll edge.

- Q: Can tinplate packaging be used for electronic products?

- Yes, tinplate packaging can be used for electronic products. Tinplate is a durable and corrosion-resistant material that provides effective protection for electronic devices. It can be customized to fit various shapes and sizes, ensuring a secure and reliable packaging solution for electronic products. Additionally, tinplate packaging can also enhance the aesthetic appeal of electronic products, making them more visually appealing to consumers.

- Q: Can tinplate be used for packaging heavy products?

- Yes, tinplate can be used for packaging heavy products. Tinplate is a strong and durable material that can withstand the weight of heavy items, making it suitable for packaging purposes. Its resistance to corrosion and ability to protect the contents from external factors further enhance its usefulness for packaging heavy products.

- Q: Both tinplate and stainless steel have corrosion protection

- Tinplate is common steel tin plating, tin coating is broken, later, because the tin is more corrosion resistant than iron, so iron will sooner corrosion. Mainly used for tins.

- Q: What are the different testing methods for tinplate packaging?

- Some of the different testing methods for tinplate packaging include visual inspection for defects or damage, measuring the thickness of the tinplate using a micrometer, performing drop tests to assess the durability and impact resistance of the packaging, conducting leakage tests to ensure the integrity of the seals, conducting corrosion resistance tests to evaluate the tinplate's resistance to rust or corrosion, and conducting performance tests to assess the packaging's ability to withstand various environmental conditions and mechanical stresses.

- Q: What are the main challenges in the disposal of tinplate products?

- The main challenges in the disposal of tinplate products include recycling limitations, contamination risks, and the need for proper waste management infrastructure. Tinplate products are often coated with other materials, such as plastic or paint, which makes recycling more difficult. Additionally, if tinplate products are not properly separated from other waste streams, they can contaminate recycling processes. Lastly, the efficient disposal of tinplate products requires adequate waste management infrastructure to handle the volume and ensure proper treatment and disposal methods are implemented.

- Q: How does tinplate contribute to the shelf life of beverages?

- Tinplate contributes to the shelf life of beverages by providing a protective barrier against light, oxygen, and moisture, which helps to prevent oxidation and spoilage. This ensures that the beverage retains its quality, taste, and freshness for a longer period of time. Additionally, tinplate cans also have excellent sealing properties, further reducing the risk of contamination and extending the shelf life of beverages.

- Q: What are the benefits of using tinplate for roofing?

- One of the main benefits of using tinplate for roofing is its durability and longevity. Tinplate is highly resistant to corrosion and can withstand harsh weather conditions, making it a reliable option for long-term use. Additionally, tinplate is lightweight, making installation easier and more efficient. It also provides excellent insulation, helping to regulate temperature and reduce energy costs. Furthermore, tinplate roofing is aesthetically pleasing, offering a sleek and modern look to any building.

- Q: How does tinplate packaging contribute to product aesthetics?

- Tinplate packaging contributes to product aesthetics by offering a visually appealing and versatile option for packaging. Its shiny and reflective surface adds a premium and luxurious look to products, enhancing their overall aesthetic appeal. Additionally, tinplate packaging can be easily customized through various printing techniques, enabling brands to create eye-catching designs, logos, and graphics that attract consumers' attention on store shelves. Its durability and ability to maintain color and shape also ensure that the product's aesthetic appeal remains intact throughout its lifespan.

Send your message to us

Prime Quality Tinplate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords