Tinplate Properties

Tinplate Properties Related Searches

Tinplate Material Tinplate Products Tinplate Coating Printing Tinplate Printed Tinplate Tinplate Printing Tinplate Production Tinplate Layout Tinplate Packaging Define Tinplate Tinplate Tins Tinplate Can Buy Tinplate Tinplate Price Tinplate China Tinplate Pails Tinplate Share Tinplate Iron Tinplate Printing Machine Tinplate Recycling Tinplate Temper Chart Tinplate Company Tinplate Factory Tinplate Studios Tinplate Products Ltd Tinplate Cans Tinplate Screener Printing Tinplate Sheet Envases Tinplate Tinplate ContainersTinplate Properties Supplier & Manufacturer from China

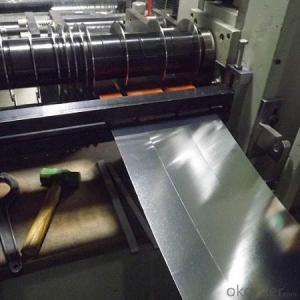

Tinplate Properties refer to the characteristics of tin-coated steel sheets, which are widely recognized for their excellent corrosion resistance, formability, and weldability. These properties make tinplate an ideal material for various applications, including food and beverage cans, automotive parts, and construction materials. Due to its versatility, tinplate is utilized across numerous industries, offering a reliable and durable solution for numerous products. As a wholesale supplier, Okorder.com boasts a vast inventory of tinplate products, ensuring that customers have access to a comprehensive range of options to suit their specific requirements. By offering a broad selection of tinplate with varying properties, Okorder.com caters to the diverse needs of its clientele, making it a go-to source for tinplate materials.Hot Products