Tinplate Share

Tinplate Share Related Searches

Tata Tinplate Share Tinplate Forum Tinplate Social Circle Tinplate Cover Buy Tinplate Tinplate Sheets Printed Tinplate Tinplate Mailbox Tinplate Tins Tinplate Recycling Tinplate China Tinplate Factory Tinplate Layout Tinplate Market Tinplate For Sale Tinplate Company Tinplate Packaging Tinplate Coating Tinplate Printing Tinplate Projects Tinplate Future Nse Tinplate Printing Tinplate Tinplate Collectables Tinplate Uk Stock Tinplate Tinplate Studios Tinplate Box Marx Tinplate Tinplate Service CenterTinplate Share Supplier & Manufacturer from China

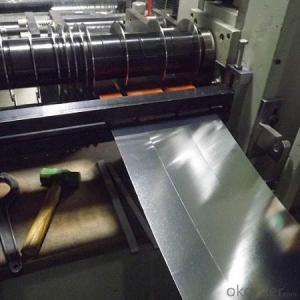

Tinplate Share encompasses a range of tin-coated steel products that are widely recognized for their durability and corrosion resistance. These products are manufactured by applying a thin layer of tin to a sheet of steel, resulting in a material that combines the strength of steel with the non-toxic properties of tin. The applications of this product are vast, as it is commonly used in the packaging industry for food cans, aerosol containers, and other consumer goods. Additionally, tinplate share products are utilized in automotive, construction, and electrical applications due to their robustness and protective qualities.Tinplate Share products are known for their versatility and are suitable for a variety of usage scenarios. They are ideal for applications where a barrier between the steel and the contents is necessary to prevent corrosion and ensure the safety and integrity of the product. Whether it's preserving food items or safeguarding electrical components, tinplate share products provide a reliable and efficient solution. The material's ability to be easily formed and welded also makes it a popular choice for various manufacturing processes.

Okorder.com stands out as a prominent wholesale supplier of Tinplate Share products, boasting a substantial inventory that caters to the diverse needs of clients across different industries. With a commitment to quality and customer satisfaction, Okorder.com ensures that the tinplate share products they offer meet the highest standards of performance and reliability. Their extensive range of products and competitive pricing make them a go-to source for businesses looking to stock up on this essential material.

Hot Products