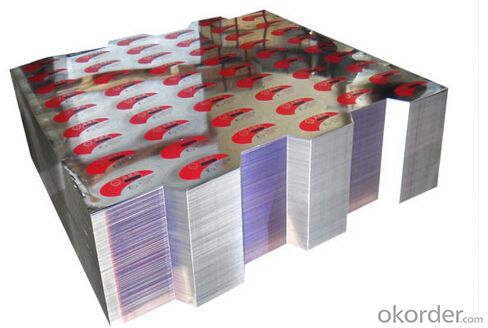

PRINTED SHEET

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are one of the main printing and coating plant in the North China, very close to the Tianjin sea port. We can undertake all kinds of tinplate, cold plate and other processing services. We have regular business with the state legislature, Kamei and other large companies by providing printing produces. Through so many years development, we have stable customers in the Southeast Asia, like Singapore and Vietnam and continuous orders. We can do Color printing, Offset printing, peritoneum, glazing and lithographic printing. Products include chemicals and food packaging used tinplate or tin free steel(TFS).

Features:

- Chemical and Corrosion Resistant

- Easily Fabricated or Welded

- Cost Effective

- Durable and flame retardant

- Excellent for outdoor exposure.

- Paintable. Weather resistant.

- High tensile, compressive, and flexural strength.

Our machines are from Japan with high quality. We have high quality control to each product.

Company management system is healthy, operational mechanism running good. After years of effort, base on the introduction, absorption, digestion of the advanced technology, techniques, equipment, we gradually set up the unique production process and technical support system which is market need-oriental and suite to the Chinese condition.

In the fierce market competition, our company will continue to pursue the excellence quality and outstanding service, and provide more and better service and service to meet customers demand on metal package home and abroad.

- Q: The difference between a matte tin plate and a bright tin plate

- Smooth tinplate:Smooth surface refers to the surface of tin in general tin, through the soft melting so that the surface has a metallic luster.

- Q: Can tinplate be used for paint cans?

- Yes, tinplate can be used for paint cans. Tinplate is a commonly used material for manufacturing paint cans due to its durability, corrosion resistance, and ability to preserve the quality of the paint inside. It also provides a smooth surface for labeling and branding purposes.

- Q: How does tinplate packaging contribute to product shelf life?

- Tinplate packaging contributes to product shelf life by providing a durable and protective barrier against external factors such as moisture, oxygen, light, and temperature fluctuations. This helps to prevent spoilage, retain product freshness, and extend the overall shelf life of the packaged goods. Additionally, tinplate packaging is resistant to corrosion, ensuring the integrity of the packaging throughout the product's shelf life.

- Q: How does the tin coating affect the appearance of tinplate?

- The tin coating on tinplate enhances its appearance by providing a bright and reflective surface. It gives the tinplate a shiny and lustrous appearance, making it visually appealing.

- Q: How does tinplate packaging contribute to product protection against light?

- Tinplate packaging contributes to product protection against light by providing a highly effective barrier that prevents light from reaching the product. The tin coating on the steel substrate acts as a reflective layer, reducing the amount of light transmission. This helps to shield the product from harmful UV radiation and other forms of light that can cause degradation, discoloration, or spoilage. Additionally, tinplate packaging can be further enhanced with additional protective coatings or lacquers that provide an additional layer of defense against light exposure, ensuring the product remains intact and protected.

- Q: What type of paint is suitable for tinplate?

- Enamel paint is the most suitable type of paint for tinplate due to its durability and ability to adhere well to the metal surface.

- Q: How does tinplate contribute to the preservation of paint products?

- Tinplate contributes to the preservation of paint products by providing a durable and protective packaging solution. It is a corrosion-resistant material that prevents the paint from coming into contact with oxygen, moisture, and other external factors that can lead to degradation or spoilage. Additionally, tinplate cans are known for their tight seals, preventing any leakage or contamination that could compromise the quality and longevity of the paint inside.

- Q: How does tinplate packaging contribute to product freshness?

- Tinplate packaging contributes to product freshness by providing a protective barrier against external factors such as air, moisture, and light. This helps to prevent oxidation and preserve the quality, taste, and aroma of the packaged product. Additionally, tinplate packaging has excellent sealing properties, ensuring that the contents remain airtight and free from contamination, thereby extending the shelf life and maintaining product freshness.

- Q: How does tinplate packaging contribute to brand recognition?

- Tinplate packaging contributes to brand recognition by providing a visually appealing and distinctive packaging solution. The shiny and durable nature of tinplate grabs consumers' attention and helps to differentiate the brand from competitors. Additionally, tinplate packaging can be customized with vibrant colors, intricate designs, and embossing techniques, which further enhances brand visibility and memorability. The premium look and feel of tinplate packaging also conveys a sense of quality and value, positively influencing consumers' perception of the brand.

- Q: How does tinplate compare to aluminum packaging in terms of cost?

- In terms of cost, tinplate tends to be more affordable compared to aluminum packaging.

Send your message to us

PRINTED SHEET

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords