Tinplate in Sheets and Coils for Cans Packing in good quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 7000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Electrolytic Tinplate in Sheets and Coils for Cans Packing Description

Due to Tinplate packaging`s good seal, nature, dark, robustness and unique decorative metal charm, it has a wide range of coverage in the packaging container industry,and common international packaging varieties. With a variety of CC tinplate material, DR materials, chrome plated and constantly enrich and promotion and development of packaging products and technology, tinplate packaging has promoted with innovation.

Because of its strong antioxidant and diverse styles, beautifully printed, tinplate containers are very popular and loved by customers, and they are widely used in food packaging, pharmaceutical packaging, commodity packaging, instrumentation, packaging, industrial packaging and so on.

With the continuous improvement of tinplate printing technology and processing technology, tinplate packaging has developed more widely.

2.Main Features of the Electrolytic Tinplate in Sheets and Coils for Cans Packing

Appearance – Electrolytic Tin Plate is characterized by its beautiful metallic luster. Products with various kinds of surface roughness are produced by selecting the surface finish of the substrate steel sheet.

Paintability and printability – Electrolytic Tin Plates have excellent paintability and printability. Printing is beautifully finished using various lacquers and inks.

Formability and strength – Electrolytic Tin Plates have got very good formability and strength. By selecting a proper temper grade, appropriate formability is obtained for different applications as well as the required strength after forming.

Corrosion resistance – Tinplate has got good corrosion resistance. By selecting a proper coating weight, appropriate corrosion resistance is obtained against container contents. Coated items should meet 24 hour 5 % salt spray requirement.

Solderability and weldability – Electrolytic Tin Plates can be joined both by soldering or welding. These properties of tinplate are used for making various types of cans.

Hygienic – Tin coating provides good and non toxic barrier properties to protect food products from impurities, bacteria, moisture, light and odours.

Safe – Tinplate being low weight and high strength makes food cans easy to ship and transport.

Eco friendly – Tinplate offers 100 % recyclability.

Tin is not good for low temperature applications since it changes structure and loses adhesion when exposed to temperatures below – 40 deg C.

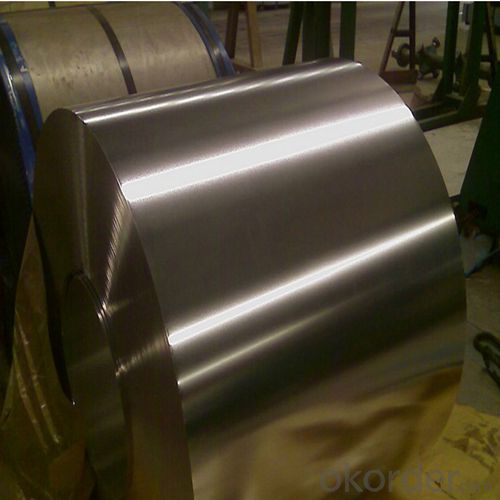

3.Electrolytic Tinplate in Sheets and Coils for Cans Packing Images

4.Electrolytic Tinplate in Sheets and Coils for Cans Packing Specification

Standard | ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

|

Material | MR,SPCC |

Thickness | 0.15mm - 0.50mm |

Width | 600mm -1150mm |

Temper | T1-T5 |

Annealing | BA & CA |

Coil Inner Diameter | 508mm |

Weight | 6-10 tons/coil 1~1.7 tons/sheets bundle |

Passivation | 311 |

Oil | DOS |

Surface | Finish,bright,stone,matte,silver |

5.FAQ of Electrolytic Tinplate in Sheets and Coils for Cans Packing

- How are the Electrolytic Tin Plates specified?

The Electrolytic Tin Plates are specified as per the steel base, extent of tempering, the coating weight, annealing method and the surface finish.

- How many types there are for base steels?

The base steels are of three types: Type MR, L, D

- Q: Can tinplate be used for promotional or gift packaging?

- Yes, tinplate can be used for promotional or gift packaging. It is a versatile material that offers durability, aesthetic appeal, and the ability to be customized with various designs and finishes. Tinplate packaging can enhance the perceived value of a product or gift, making it an excellent choice for promotional purposes.

- Q: Can tinplate be reused after recycling?

- Yes, tinplate can be reused after recycling. Recycling tinplate involves melting it down to form new sheets of tinplate, which can then be used to manufacture various products such as cans, containers, and packaging materials. This process helps to conserve resources and reduce waste.

- Q: Can tinplate packaging be used for beverages?

- Yes, tinplate packaging can be used for beverages. Tinplate is a common and suitable material for packaging beverages as it is lightweight, durable, and provides excellent protection against air, light, and moisture. It is commonly used for packaging beverages like canned drinks, juices, and carbonated beverages.

- Q: How does tinplate packaging contribute to product protection against moisture?

- Tinplate packaging provides a reliable barrier against moisture due to its inherent properties. The tin coating on the steel substrate prevents direct contact between the product and moisture, acting as a protective layer. This barrier effectively blocks the entry of external moisture, reducing the risk of corrosion, spoilage, or damage to the product. Additionally, tinplate packaging is often hermetically sealed, further enhancing its moisture resistance and preserving the quality and shelf life of the enclosed product.

- Q: What are the typical lead times for tinplate production?

- The typical lead times for tinplate production can vary depending on factors such as the quantity required, complexity of the design, and the manufacturer's production capacity. However, on average, lead times for tinplate production usually range from several weeks to a few months.

- Q: Does tinplate require any specific handling or storage conditions?

- Yes, tinplate does require specific handling and storage conditions. It should be protected from moisture and kept in a dry environment to prevent rusting. Additionally, it is recommended to store tinplate in a cool and well-ventilated area to maintain its quality and prevent any potential damage.

- Q: Can tinplate be used for packaging pet care products?

- Yes, tinplate can be used for packaging pet care products. Tinplate is a durable and lightweight material that provides good protection against moisture, ensuring the quality and safety of pet care products. Additionally, tinplate can be easily shaped and decorated, making it an ideal choice for attractive and functional packaging.

- Q: Can tinplate packaging be used for pet care products?

- Yes, tinplate packaging can be used for pet care products. Tinplate is a durable and versatile material that can protect and preserve pet care products such as food, treats, and grooming items. It is resistant to corrosion, tampering, and can be easily customized with attractive designs and branding. Additionally, tinplate is recyclable, making it an environmentally friendly choice for pet care packaging.

- Q: What are the common forms of corrosion that affect tinplate?

- Tinplate commonly experiences three forms of corrosion: uniform corrosion, pitting corrosion, and tin whisker growth. Uniform corrosion occurs evenly across the surface, leading to a thinning of the tin coating. Pitting corrosion, on the other hand, creates localized holes or pits, compromising the integrity of the tinplate. Lastly, tin whisker growth involves the formation of tiny, crystalline structures that can lead to short-circuits or other electrical issues.

- Q: How is tinplate used in the manufacturing of household appliances?

- Tinplate is commonly used in the manufacturing of household appliances as it provides a protective and decorative coating. It is often used to create the exterior casing of appliances such as refrigerators, dishwashers, and washing machines. The tin coating helps prevent corrosion, adds durability, and enhances the overall appearance of the appliances.

Send your message to us

Tinplate in Sheets and Coils for Cans Packing in good quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 7000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords