Tinplate Coil and sheet for making food cans

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 400000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

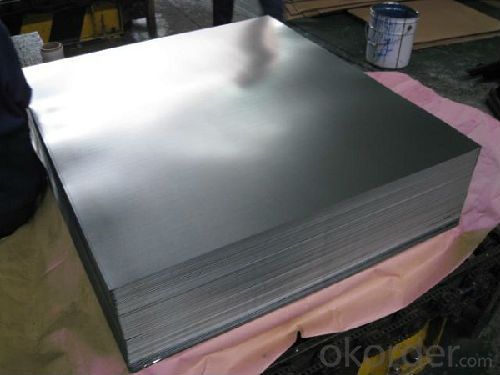

Prime Quality Tinplate Sheets Details

1.Structure of Description

Electrolytic Tinplate Sheets is one of the metal packing materials, which is widely used for making painting cans ,chemical package cans , electrical cable ,battery and metal printing etc. For caps, there are some customers also need TFS, if you have some demand for TFS,also can contact with us.

2. Main Features

Steady and high quality

Fast shipment

Good experience for export work

For the surface, Plate uniform in thickness,uniform and smooth tin coating, without flaws,rusts,scratch,wave,nick of tin coating etc.

Minumum Order Quantity: 25 MT Loading Port:China Main Port

Annual Capacity: 400,000MT Payment Terms:TT or LC

Product Specifications:

Prime Quality Tinplate Sheets Usage and Applications

Prime Quality Tinplate Sheets Specifications

Standard : GB2520-2000 ,JIS G3303

Steel type : SPCC

Coating : 2.8/2.8

Surface: Bright, Stone ,

Thickness:0.18

Width :600MM~1000MM

Temper : T1~T5

Package: tinplate wrapped completely with an inner cover of plastic or waterproof papers with vorners protected with metal angels.

Applications

Chemicals and painting cans

Dry food cans, such as fancy cans, biscuit cans, milk power cans, tea cans

Liquid food cans, such as edible oil cans, beverage cans, Tomato paste cans

Sea food cans

Crown corks, easy open ends(EOE)

Electrical machinery parts

Bakeware and household kitchen parts

FAQ

A. What is the package of tinplate? (Referred as below)

For sheets, thin plastic film + rust-proof paper + metallic cover + metallic angles+ steel band strips + fumigated wooden pallet.

For coil, thin plastic film + rust proof paper + metallic cover + steel band strips + fumigated wooden pallet

B. The surface of tinplate could you supply?

Stone finish, Bright finish, Matte finish, Silver finish

- Q:Can tinplate be used for electrical appliances?

- Yes, tinplate can be used for electrical appliances. Tinplate is a thin steel coated with a layer of tin, making it corrosion-resistant and suitable for various applications, including electrical appliances. The tin coating provides an excellent barrier against moisture and oxidation, making it a reliable material for electrical components and enclosures.

- Q:What are the latest innovations in tinplate technology?

- Some of the latest innovations in tinplate technology include advancements in coatings, such as new environmentally friendly and corrosion-resistant coatings, as well as improved printing techniques for enhanced graphic quality on tinplate packaging. Additionally, there have been developments in lightweighting techniques to reduce the overall weight of tinplate while maintaining its strength and durability.

- Q:What are the common packaging formats for tinplate?

- The common packaging formats for tinplate include cans, containers, and tins.

- Q:What are the different methods of recycling tinplate packaging?

- The different methods of recycling tinplate packaging include sorting, cleaning, shredding, melting, and reprocessing. Sorting involves separating tinplate packaging from other materials. Cleaning removes any contaminants from the tinplate. Shredding breaks down the tinplate into smaller pieces. Melting helps to separate the tin coating from the steel base. Finally, reprocessing involves transforming the separated tin and steel into new products or materials.

- Q:What are the main regulations governing tinplate recycling?

- The main regulations governing tinplate recycling vary by country and region. However, some common regulations include waste management laws, recycling targets, and regulations regarding the collection, sorting, and processing of tinplate materials. These regulations aim to promote the proper disposal and recycling of tinplate, ensuring environmental sustainability and resource conservation.

- Q:How is tinplate recycled and what are the benefits of recycling?

- Tinplate is commonly recycled through a process called "tin can recycling." In this process, tin cans are collected, sorted, and then shredded into small pieces. The shredded tinplate is then melted down to remove any impurities, and the molten metal is poured into molds to create new tinplate products. The benefits of recycling tinplate are numerous. Firstly, recycling tinplate helps conserve natural resources as it reduces the need for mining and extraction of new raw materials. Additionally, recycling tinplate reduces energy consumption and greenhouse gas emissions compared to producing tinplate from scratch. Moreover, recycling tinplate reduces the burden on landfill sites, as tin cans can take years to decompose. Finally, recycling tinplate helps create job opportunities in the recycling industry, contributing to the economy. Overall, tinplate recycling is an eco-friendly and sustainable solution that brings multiple environmental and economic benefits.

- Q:What are the common industry standards for tinplate?

- The common industry standards for tinplate include specifications for the tin coating weight, the base metal thickness, surface finish, and the adhesion of the tin coating. These standards ensure consistency and quality in the production of tinplate, allowing for its effective use in various industries such as packaging, automotive, and construction.

- Q:How is tinplate coated with polymer films?

- Tinplate is coated with polymer films through a process called lamination. This involves applying a layer of polymer film onto the surface of the tinplate using heat and pressure. The polymer film adheres to the tinplate, providing a protective barrier against corrosion and enhancing its durability.

- Q:What are the common sizes and shapes of tinplate products?

- Common sizes and shapes of tinplate products vary depending on their purpose and industry. However, some commonly seen sizes include cans ranging from small containers for food and beverages (such as soda cans) to larger ones for bulk products (such as paint cans). Tinplate products also come in various shapes, including rectangular, cylindrical, and irregular forms, to cater to different packaging needs and maximize storage efficiency.

- Q:How does tinplate perform in terms of magnetic properties?

- Tinplate is not inherently magnetic, as it is made by coating a thin layer of tin onto steel. However, the steel base of tinplate can retain its magnetic properties.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tinplate Coil and sheet for making food cans

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 400000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords