Tin Free Steel and Tinplate for Prime Quality and best Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 40900 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

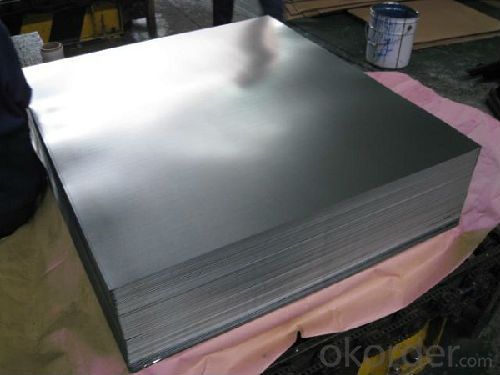

Prime Quality Tinplate Sheets Details

1.Structure of Description

Electrolytic Tinplate Sheets is one of the metal packing materials, which is widely used for making painting cans ,chemical package cans , electrical cable ,battery and metal printing etc. For caps, there are some customers also need TFS, if you have some demand for TFS,also can contact with us.

2. Main Features

Steady and high quality

Fast shipment

Good experience for export work

For the surface, Plate uniform in thickness,uniform and smooth tin coating, without flaws,rusts,scratch,wave,nick of tin coating etc.

Minumum Order Quantity: 25 MT Loading Port:China Main Port

Annual Capacity: 400,000MT Payment Terms:TT or LC

Product Specifications:

Prime Quality Tinplate Sheets Usage and Applications

Prime Quality Tinplate Sheets Specifications

Standard : GB2520-2000 ,JIS G3303

Steel type : SPCC

Coating : 2.8/2.8

Surface: Bright, Stone ,

Thickness:0.18

Width :600MM~1000MM

Temper : T1~T5

Package: tinplate wrapped completely with an inner cover of plastic or waterproof papers with vorners protected with metal angels.

Applications

Chemicals and painting cans

Dry food cans, such as fancy cans, biscuit cans, milk power cans, tea cans

Liquid food cans, such as edible oil cans, beverage cans, Tomato paste cans

Sea food cans

Crown corks, easy open ends(EOE)

Electrical machinery parts

Bakeware and household kitchen parts

FAQ

A. What is the package of tinplate? (Referred as below)

For sheets, thin plastic film + rust-proof paper + metallic cover + metallic angles+ steel band strips + fumigated wooden pallet.

For coil, thin plastic film + rust proof paper + metallic cover + steel band strips + fumigated wooden pallet

B. The surface of tinplate could you supply?

Stone finish, Bright finish, Matte finish, Silver finish

- Q: What are the main differences between tinplate and tinplate laminates in terms of design flexibility?

- Tinplate offers limited design flexibility due to its rigid nature, while tinplate laminates provide greater design flexibility as they can be combined with other materials, allowing for more creative and versatile packaging options.

- Q: How does tinplate contribute to the overall convenience of packaging?

- Tinplate contributes to the overall convenience of packaging by providing a durable, lightweight, and easily recyclable material for various consumer goods. Its corrosion resistance properties ensure the longevity and freshness of packaged products, while its versatility allows for different shapes and sizes of packaging. Additionally, tinplate's ability to be easily processed and printed on facilitates branding and labeling, enhancing the convenience and attractiveness of the packaging.

- Q: How does tinplate contribute to the performance of ammunition?

- Tinplate contributes to the performance of ammunition by providing a durable and corrosion-resistant outer coating. This protective layer ensures that the ammunition remains intact and functional even under harsh environmental conditions, preventing rust and degradation. Additionally, tinplate's smooth surface facilitates easy loading and extraction of ammunition, enhancing reliability and efficiency during use. Overall, tinplate plays a crucial role in preserving the quality and performance of ammunition, ensuring its effectiveness and safety for users.

- Q: What are the common challenges in recycling tinplate packaging?

- Some common challenges in recycling tinplate packaging include the separation of tinplate from other materials, such as plastic or paper, which can be time-consuming and costly. Additionally, the removal of any residual contents or labels from the tinplate can be challenging. The recycling process may also be complicated by the presence of coatings or laminations on the tinplate. Finally, the availability of recycling facilities specifically equipped to handle tinplate packaging can be limited, leading to logistical difficulties in the recycling process.

- Q: How does tinplate perform in terms of recyclability?

- Tinplate is highly recyclable and has one of the highest recycling rates among packaging materials. It can be easily separated from other materials during the recycling process and reused to create new products, making it an environmentally friendly choice.

- Q: How to open cans

- Put the tins of canned fruits soaked in hot water for 3-5 minutes, so that the tank gas temperature rises, the pressure is increased, which is the principle of expansion and contraction. Turn the canned fruit bottle upside down for a while. When the liquid in it breaks down the vacuum inside and outside, tap it in the bottom with your palm and pull it gently. It's easy to pull apart.

- Q: How is tinplate coated for gift packaging?

- Tinplate is typically coated for gift packaging through a process called electrolytic tinplating. This involves immersing the tinplate in an electrolyte solution and passing an electric current through it, causing a layer of tin to be deposited onto the surface of the tinplate. This tin coating provides a protective barrier against corrosion and enhances the overall appearance of the packaging, making it more suitable for gift presentation.

- Q: What are the different types of tinplate coatings available?

- There are several types of tinplate coatings available, including electrolytic tinplate (ETP), tin-free steel (TFS), and lacquered tinplate. ETP is the most common type and it provides excellent corrosion resistance and a shiny appearance. TFS, on the other hand, does not contain tin and is coated with a layer of chromium or chromium oxide, offering similar corrosion resistance as ETP. Lacquered tinplate is coated with a layer of lacquer, providing additional protection against corrosion and enhancing the appearance of the tinplate.

- Q: What are the different ways to recycle tinplate packaging?

- There are several different ways to recycle tinplate packaging. One common method is to sort and separate the tinplate from other materials, such as paper or plastic, at recycling facilities. This allows the tinplate to be melted down and used to create new products. Another option is to reuse tinplate packaging for storage purposes, such as using empty tin cans to organize small items. Additionally, some people repurpose tinplate packaging for crafts or DIY projects, giving it a new life and purpose.

- Q: How does tinplate contribute to the shelf life of beverages?

- Tinplate contributes to the shelf life of beverages by providing a protective barrier against light, oxygen, and moisture, which helps to prevent oxidation and spoilage. This ensures that the beverage retains its quality, taste, and freshness for a longer period of time. Additionally, tinplate cans also have excellent sealing properties, further reducing the risk of contamination and extending the shelf life of beverages.

Send your message to us

Tin Free Steel and Tinplate for Prime Quality and best Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 40900 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords