Tinplate of Prime or Secondary

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

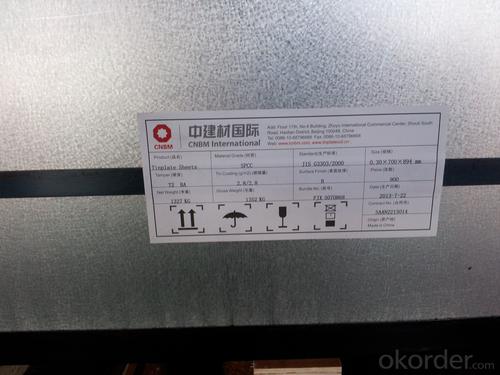

Our Tinplates Specification:

Standard: ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

Material: MR,SPCC

Thickness:0.15mm - 0.50mm

Width: 600mm -1150mm

Temper: T1-T5; DR8 - DR10;

Annealing: BA & CA

Passivation:311

Oil: DOS

Surface: Finish,bright,stone,matte,silver

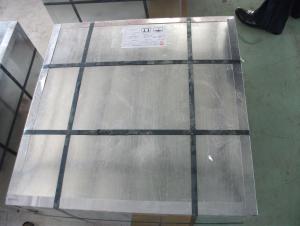

Packing:

1、For sheets: plastic or waterproof paper, metallic cover and angles, steel strips,wooden pallet.

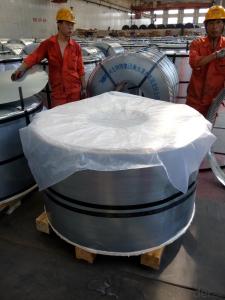

2、For Coils: plastic or waterproof paper,plastic protect plate,steel strips.

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil

Application: widely used in every kinds of packing cans,such as tea packaging cans, painting packaging cans, chemical packaging cans and dry food packaging cans; and also mechanical parts

Both Prime and Second Quality Are Available!!!

- Q: How thick is tinplate?

- Tinplate typically has a thickness ranging from 0.13 to 0.49 millimeters.

- Q: What are the common storage and handling requirements for tinplate?

- The common storage and handling requirements for tinplate include keeping it in a clean and dry environment to prevent rusting or corrosion. It should be stored in a well-ventilated area away from direct sunlight and sources of heat. Tinplate should be handled with care to avoid any sharp impacts or bending, as it can affect its structural integrity. It is also important to stack tinplate properly, ensuring that there is no excessive weight on top of it to prevent deformation. Regular inspection and maintenance are necessary to detect any signs of damage or corrosion early on.

- Q: What printing methods are used on tinplate?

- The common printing methods used on tinplate include lithography, offset printing, and silk screen printing.

- Q: What are the properties of tinplate?

- Tinplate is a type of steel that is coated with a thin layer of tin, which imparts several key properties. It is highly corrosion-resistant, making it suitable for packaging food and beverages. Tinplate also has excellent heat resistance, making it ideal for products that need to withstand high temperatures during processing or cooking. Additionally, it has good formability, allowing it to be easily shaped and molded into various sizes and designs.

- Q: What are the welding methods used for tinplate?

- The welding methods commonly used for tinplate are spot welding, seam welding, and resistance welding. These methods ensure a strong and durable bond between tinplate sheets, making them suitable for various applications such as food cans and packaging materials.

- Q: What are the different types of tinplate seams?

- The different types of tinplate seams include lap seams, double seam, triple seam, and lock seam.

- Q: What are the main challenges in tinplate labeling?

- The main challenges in tinplate labeling include ensuring the label adheres well to the curved surface of the tinplate, maintaining label durability and resistance to moisture and other external factors, achieving accurate and consistent placement of the label, and ensuring the label does not peel or bubble over time.

- Q: What are the main advantages of using tinplate for electrical enclosures?

- The main advantages of using tinplate for electrical enclosures include its high strength and durability, excellent corrosion resistance, and good electrical conductivity. Tinplate is also lightweight and easy to form, making it a cost-effective choice for manufacturing enclosures. Additionally, tinplate is recyclable, making it an environmentally friendly option for electrical applications.

- Q: Can tinplate be used for coffee or tea packaging?

- Yes, tinplate can be used for coffee or tea packaging. Tinplate is a commonly used material for such packaging due to its durability, ability to maintain product freshness, and resistance to moisture and oxygen. Additionally, tinplate offers excellent printing capabilities, making it an ideal choice for branding and product information display.

- Q: How does tinplate contribute to the safety of toys?

- Tinplate contributes to the safety of toys by providing a protective coating that prevents direct contact between the toy and any potentially harmful substances. This coating acts as a barrier against corrosion, ensuring that the toy remains safe and free from any toxic materials that may be present in the metal or paint used. Additionally, tinplate is durable and resistant to damage, reducing the risk of children being exposed to sharp edges or broken pieces.

Send your message to us

Tinplate of Prime or Secondary

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords