All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

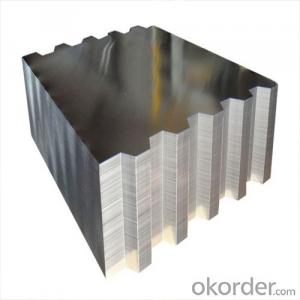

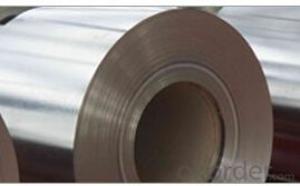

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the main factors that affect the corrosion resistance of electrolytic tinplate coil in industrial environments?

The main factors that affect the corrosion resistance of electrolytic tinplate coil in industrial environments include the quality of the tin coating, the presence of contaminants or impurities in the environment, exposure to moisture or humidity, and the pH level of the surrounding atmosphere. Other factors such as temperature, exposure to chemicals, and mechanical damage can also impact the corrosion resistance of the tinplate coil.

What are the different temper conditions for electrolytic tinplate coil?

The different temper conditions for electrolytic tinplate coil are categorized as full hard (FH), half hard (HH), quarter hard (QH), and soft (S).

Can electrolytic tinplate coil be used for packaging medical devices?

Yes, electrolytic tinplate coil can be used for packaging medical devices. It provides a protective barrier against moisture and corrosion, ensuring the integrity and safety of the medical devices during storage and transportation.

Can electrolytic tinplate coil be used for printing or labeling purposes?

Yes, electrolytic tinplate coil can be used for printing or labeling purposes. The tin coating on the surface of the coil provides excellent printability, making it suitable for various printing and labeling applications.

Can the coil be coated with other materials for enhanced performance?

Yes, the coil can be coated with other materials to enhance its performance. Coatings such as polymers, ceramics, or metals can be applied to improve factors such as conductivity, resistance to corrosion, insulation, or heat dissipation. These coatings can enhance the coil's efficiency, durability, and overall performance.

Wholesale Electrolytic Tinplate Coil from supplier in Benin

Our team of experts is dedicated to providing top-notch customer service and ensuring that you receive the highest quality products at competitive prices. We understand the unique requirements of the Benin market and are committed to meeting your specific needs.

Whether you are looking for Electrolytic Tinplate Coils for packaging, canning, or any other application, we have a wide range of options to choose from. Our products are sourced from trusted manufacturers and undergo stringent quality control measures to ensure their reliability and durability.

In addition to our sales services, we also offer technical support to help you make informed decisions about the best products for your projects. Our team is well-versed in the technical aspects of Electrolytic Tinplate Coils and can provide guidance on product specifications, applications, and any other technical queries you may have.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the financial strength and resources to handle large-scale procurement projects. Our well-established supply chain network allows us to efficiently source and deliver Electrolytic Tinplate Coils to clients in Benin, ensuring timely and reliable deliveries.

We value long-term partnerships and strive to build strong relationships with our clients in Benin. Our commitment to customer satisfaction is reflected in our dedication to providing exceptional service and high-quality products. Let us be your trusted partner for all your Electrolytic Tinplate Coil needs in Benin. Contact us today to discuss your requirements and experience the difference of working with a reliable and experienced supplier.

Whether you are looking for Electrolytic Tinplate Coils for packaging, canning, or any other application, we have a wide range of options to choose from. Our products are sourced from trusted manufacturers and undergo stringent quality control measures to ensure their reliability and durability.

In addition to our sales services, we also offer technical support to help you make informed decisions about the best products for your projects. Our team is well-versed in the technical aspects of Electrolytic Tinplate Coils and can provide guidance on product specifications, applications, and any other technical queries you may have.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the financial strength and resources to handle large-scale procurement projects. Our well-established supply chain network allows us to efficiently source and deliver Electrolytic Tinplate Coils to clients in Benin, ensuring timely and reliable deliveries.

We value long-term partnerships and strive to build strong relationships with our clients in Benin. Our commitment to customer satisfaction is reflected in our dedication to providing exceptional service and high-quality products. Let us be your trusted partner for all your Electrolytic Tinplate Coil needs in Benin. Contact us today to discuss your requirements and experience the difference of working with a reliable and experienced supplier.