Prime or Secondary Quality Tinplate ETP

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Our Tinplates Specification:

Standard: ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

Material: MR,SPCC

Thickness:0.15mm - 0.50mm

Width: 600mm -1150mm

Temper: T1-T5; DR8 - DR10;

Annealing: BA & CA

Passivation:311

Oil: DOS

Surface: Finish,bright,stone,matte,silver

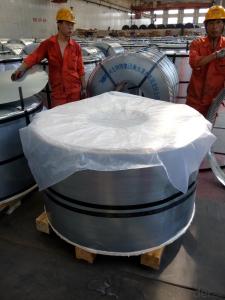

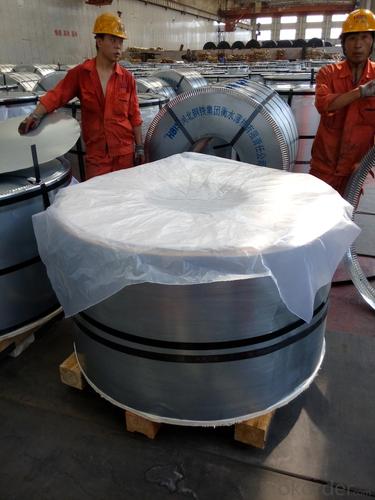

Packing:

1、For sheets: plastic or waterproof paper, metallic cover and angles, steel strips,wooden pallet.

2、For Coils: plastic or waterproof paper,plastic protect plate,steel strips.

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil

Application: widely used in every kinds of packing cans,such as tea packaging cans, painting packaging cans, chemical packaging cans and dry food packaging cans; and also mechanical parts

Both Prime and Second Quality Are Available!!!

- Q: What are the environmental impacts of producing tinplate?

- The production of tinplate has several environmental impacts. Firstly, the extraction of tin ore involves mining activities, which can lead to deforestation, habitat destruction, and soil erosion. Additionally, the refining and smelting processes used to convert tin ore into tinplate require a significant amount of energy, contributing to greenhouse gas emissions and air pollution. Furthermore, the production of tinplate involves the use of various chemicals, such as acids and solvents, which can contaminate water sources if not properly managed. Lastly, the disposal of waste materials generated during the production process, including slag and other byproducts, can pose a risk to soil and water quality if not appropriately treated or disposed of. Overall, the production of tinplate has a range of environmental impacts that need to be carefully managed and mitigated.

- Q: Tinplate also known as what? What is the density of it?

- Tin plays a major role in preventing corrosion and rusting. It will be the steel strength and formability and corrosion resistance of tin soldering, and beautiful appearance with a material, corrosion resistant, non-toxic, high strength and good ductility properties.

- Q: How is tinplate coated with tin?

- Tinplate is coated with tin through a process called electrolytic tinning. In this process, the tinplate is immersed in an electrolyte bath containing tin salts. An electric current is then passed through the bath, causing the tin ions to be attracted to the steel surface of the tinplate. As a result, a thin layer of tin is deposited onto the steel, providing it with corrosion resistance and enhanced appearance.

- Q: Can tinplate be used for electrical appliances?

- Yes, tinplate can be used for electrical appliances. Tinplate is a thin sheet of steel coated with a layer of tin, which provides excellent corrosion resistance and electrical conductivity. This makes it suitable for use in various electrical appliances such as capacitors, transformers, and electrical enclosures.

- Q: How does tinplate affect the overall product shelf appeal?

- Tinplate can significantly enhance the overall product shelf appeal due to its attractive and glossy appearance. The metallic finish of tinplate gives products a premium and luxurious look, making them stand out among competitors on store shelves. Additionally, tinplate's durability and ability to maintain its shape and color over time improve the product's presentation, creating a positive impression on consumers.

- Q: Can tinplate be used for construction applications?

- Yes, tinplate can be used for construction applications. Tinplate, which is a thin steel sheet coated with a layer of tin, offers several advantages such as strength, durability, and corrosion resistance. It is commonly used in construction for various applications including roofing, siding, wall panels, and decorative elements. Additionally, tinplate can be easily formed and shaped, making it suitable for different construction needs.

- Q: What are the advantages of using tinplate for furniture?

- One of the advantages of using tinplate for furniture is its durability. Tinplate is known for its resistance to corrosion, ensuring that furniture made from it will have a longer lifespan. Additionally, tinplate is lightweight yet sturdy, making it easy to move and rearrange furniture without compromising its structural integrity. Another advantage is its versatility in design. Tinplate can be easily molded into various shapes and forms, allowing for creative and unique furniture designs. Lastly, tinplate is also an eco-friendly option as it can be recycled, reducing waste and promoting sustainability in the furniture industry.

- Q: How does tinplate perform in terms of fire resistance?

- Tinplate has poor fire resistance properties due to its high heat conductivity, which means it can quickly transfer heat and ignite surrounding materials.

- Q: What are the main applications of tinplate in the medical industry?

- Tinplate is commonly used in the medical industry for packaging purposes, specifically for storing and preserving medical devices, pharmaceutical products, and other sensitive healthcare items. Its corrosion resistance and ability to protect against contamination make it ideal for ensuring the safety and sterility of medical supplies. Additionally, tinplate's light weight and durability make it suitable for portable medical devices and portable packaging solutions.

- Q: How is tinplate corrosion resistant?

- Tinplate is corrosion resistant due to the thin layer of tin coating that is applied to the surface of the steel. This tin layer acts as a barrier, preventing oxygen and moisture from coming into direct contact with the steel, which helps to inhibit the formation of rust and corrosion.

Send your message to us

Prime or Secondary Quality Tinplate ETP

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords