Tinplate ETP OF Prime or Secondary Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Our Tinplates Specification:

Standard: ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

Material: MR,SPCC

Thickness:0.15mm - 0.50mm

Width: 600mm -1150mm

Temper: T1-T5; DR8 - DR10;

Annealing: BA & CA

Passivation:311

Oil: DOS

Surface: Finish,bright,stone,matte,silver

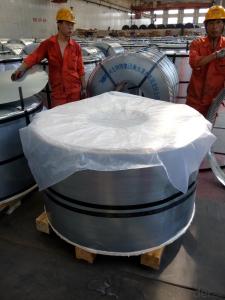

Packing:

1、For sheets: plastic or waterproof paper, metallic cover and angles, steel strips,wooden pallet.

2、For Coils: plastic or waterproof paper,plastic protect plate,steel strips.

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil

Application: widely used in every kinds of packing cans,such as tea packaging cans, painting packaging cans, chemical packaging cans and dry food packaging cans; and also mechanical parts

Both Prime and Second Quality Are Available!!!

- Q: How does tinplate contribute to the resistance of marine equipment?

- Tinplate contributes to the resistance of marine equipment by providing a protective coating that helps prevent corrosion and oxidation caused by exposure to saltwater and other harsh marine environments.

- Q: What are the different ways to label tinplate packaging?

- There are several ways to label tinplate packaging, including using adhesive labels, direct printing on the surface, embossing or debossing the tinplate, or using lithography to transfer a design onto the packaging.

- Q: What are the different coating weights available for tinplate?

- The different coating weights available for tinplate typically range from 1.1 to 11.2 grams per square meter (g/m²).

- Q: What are the common sizes of tinplate sheets?

- The common sizes of tinplate sheets typically range from 0.15mm to 0.5mm in thickness, and can vary in width from 600mm to 1200mm.

- Q: How does tinplate packaging contribute to product protection against moisture?

- Tinplate packaging provides a reliable barrier against moisture due to its inherent properties. The tin coating on the steel substrate prevents direct contact between the product and moisture, acting as a protective layer. This barrier effectively blocks the entry of external moisture, reducing the risk of corrosion, spoilage, or damage to the product. Additionally, tinplate packaging is often hermetically sealed, further enhancing its moisture resistance and preserving the quality and shelf life of the enclosed product.

- Q: What are the advantages of using tinplate for stationery and office supplies?

- One advantage of using tinplate for stationery and office supplies is its durability. Tinplate is known for its strength and resistance to corrosion, making it a long-lasting material for items like pen holders, paper trays, or pencil cases. Additionally, tinplate is highly recyclable, making it an eco-friendly choice for sustainable office supplies. Its sleek and shiny appearance also adds a touch of elegance and professionalism to the products, making them visually appealing.

- Q: How do you clean the dust and trace oil on tin containers?

- Water based cleaning method: that is, with clean water and cleaning agent to remove oil method, the use of water washing process. This process started relatively late in the country, and the technical strength of various manufacturers formula is uneven, of which the more representative of public praise is "evergreen peak" brand CLF water-based cleaning agent series.

- Q: How does the printing process affect the durability of tinplate?

- The printing process can have both positive and negative effects on the durability of tinplate. On one hand, the application of a protective coating during the printing process can enhance the tinplate's resistance to corrosion, scratches, and other forms of damage. This can significantly improve its overall durability. On the other hand, if the printing process is not done properly or if low-quality inks or coatings are used, it can weaken the tinplate's protective layer, making it more prone to wear and tear. Therefore, the printing process plays a crucial role in determining the durability of tinplate.

- Q: What is the thickness range of tinplate?

- The thickness range of tinplate typically varies between 0.14mm and 0.6mm.

- Q: Can tinplate be used for coffee or tea packaging?

- Yes, tinplate can be used for coffee or tea packaging. Tinplate is a commonly used material for such packaging due to its durability, ability to maintain product freshness, and resistance to moisture and oxygen. Additionally, tinplate offers excellent printing capabilities, making it an ideal choice for branding and product information display.

Send your message to us

Tinplate ETP OF Prime or Secondary Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords