Tinplate Temper Chart

Tinplate Temper Chart Related Searches

Tinplate Price Chart Tinplate Coating Tinplate Properties Tinplate Layout O Scale Tinplate Printed Tinplate Tinplate Material Printing Tinplate Lacquered Tinplate Tinplate Printing Tinplate Tins Tinplate Screener Tinplate Price Trend Buy Tinplate Tinplate Cover Printing Tinplate Sheet Tinplate Packaging Tinplate Sheet Prices Tinplate Forum Tinplate Sheets Tinplate Products Tinplate Recycling Tinplate China Tinplate Sheet Price Nse Tinplate Tinplate For Sale Tinplate Share Printed Tinplate Sheets Standard Gauge Tinplate Italy TinplateTinplate Temper Chart Supplier & Manufacturer from China

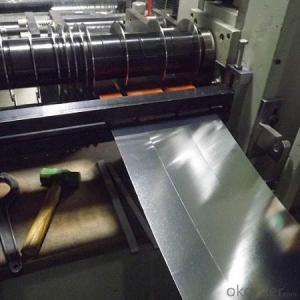

Tinplate Temper Chart refers to the classification and description of various tempers or hardness levels of tinplate materials. These tempers are essential in determining the mechanical properties and suitability of tinplate for different applications. The chart helps users to identify the appropriate tinplate temper for their specific needs, ensuring optimal performance and durability.Tinplate Temper Chart is widely used in industries such as packaging, construction, automotive, and consumer goods. It is particularly important in the manufacturing of food and beverage cans, as well as in the production of various containers and closures. By understanding the different tempers, manufacturers can select the right tinplate for their products, ensuring that they meet the required specifications and maintain their structural integrity throughout their lifecycle.

Okorder.com is a leading wholesale supplier of Tinplate Temper Chart, offering a vast inventory of products to cater to the needs of various industries. As a reliable source for tinplate materials, Okorder.com ensures that customers have access to high-quality products at competitive prices. By providing a comprehensive range of tinplate tempers, Okorder.com enables businesses to find the perfect solution for their specific requirements, streamlining their manufacturing processes and enhancing their product offerings.

Hot Products