Electrical Tinplate, JIS G3303 Standard For Food Cans & Industrial Cans

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Tinplate, as the name suggests, is coated on both sides with pure tin at various coating weights between 1 and 12 grams per square meter.

It has an extremely beautiful metallic luster as well as excellent properties in corrosion resistance, solder ability, and weld ability.

TINPLATE SPECIFICATION

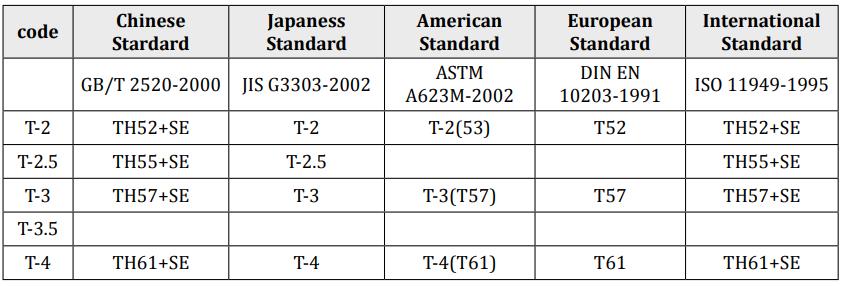

1.Reference standard: GB/T 2520-2000,JIS G3303-2002 and DIN EN 10203-1991

2. Raw material: MR and SPCC

3.Thickness: 0.13 to 0.5mm

4.Width: 600-1050mm

5.Coil diameter: ID 420mm or 508mm

6.Temper: T1~T5,DR8~DR10

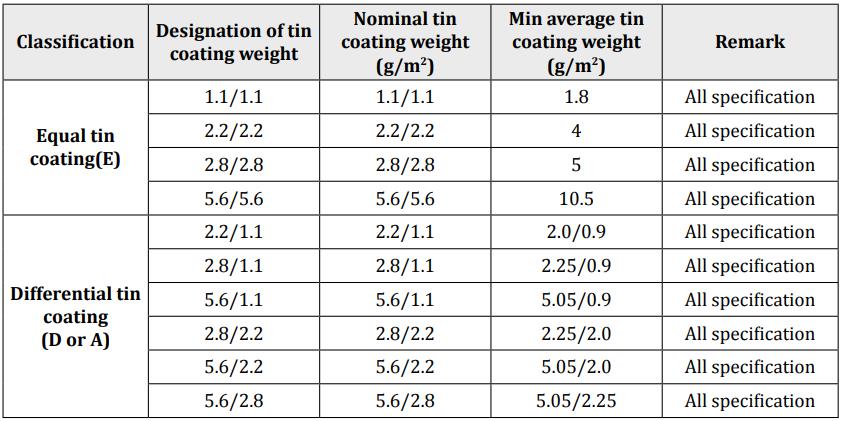

7.Tin coating: 1.1g~11.2g, We can produce according to customer's requests.

8. Applications: paint, chemical and other usage can make battery, electric cable and other industries

9. Package: anti-rust paper, corner protected. Sheets or coils according customer's requests

STANDARD

SURFACE

| Marks | Surface state | Characteristics |

| B | Bright rough | Glazed surface obtained after melting treatment of electrotinned smooth raw material strip featuring certain oriented rubstone figure. |

| RR | St hStone rough | Glazed surface obtained after melting treatment of electrotinned raw material strip featuringg p g certain oriented rubstone figure. |

| S | Silver rough | Glazed surface obtained after melting treatment of electrotinned raw material strip with rough matt surface. |

COATING

APPLICATION

Tinplate is widely used for making all types of containers, electrical machinery parts and many other products.

- Q: How does tinplate contribute to the overall sustainability of packaging?

- Tinplate contributes to the overall sustainability of packaging in several ways. Firstly, tinplate is a highly durable and long-lasting material, which means that packaging made from tinplate can be reused and recycled multiple times without losing its quality. This helps reduce the need for producing new packaging materials, conserving resources and minimizing waste. Additionally, tinplate is 100% recyclable, meaning that it can be easily recovered and turned into new products, reducing the environmental impact associated with its disposal. Moreover, tinplate offers excellent protection and preservation properties, ensuring the longevity and safety of packaged goods, thus reducing food waste and promoting sustainable consumption. Overall, tinplate packaging plays a significant role in achieving a circular economy by minimizing waste generation, conserving resources, and promoting sustainable practices.

- Q: What are the different ways to recycle tinplate containers?

- There are several different ways to recycle tinplate containers. One common method is to bring them to a local recycling center where they can be sorted and processed for recycling. These containers are typically made of steel or aluminum, which can be melted down and used to create new products. Another option is to reuse tinplate containers for storage or other purposes before eventually recycling them. Additionally, some communities offer curbside recycling programs where tinplate containers can be collected alongside other recyclable materials.

- Q: What are the common printing techniques for tinplate?

- The common printing techniques for tinplate include lithography, offset printing, and silk-screen printing.

- Q: What are the main applications of tinplate in the music industry?

- Tinplate is primarily used in the music industry for the production of cans for storing and preserving musical instruments, such as drums and cymbals. It provides a durable, corrosion-resistant and lightweight solution for packaging and transporting these instruments, ensuring their protection and longevity. Additionally, tinplate is also used for manufacturing components of musical instruments, such as reeds for woodwind instruments or small parts for stringed instruments, due to its malleability and ability to create intricate shapes.

- Q: What are the main manufacturers of tinplate?

- The main manufacturers of tinplate include companies like ArcelorMittal, Tata Steel, Thyssenkrupp, Nippon Steel Corporation, and JFE Steel Corporation.

- Q: How does tinplate contribute to the preservation of paint products?

- Tinplate contributes to the preservation of paint products by providing a protective barrier between the paint and external elements. It prevents corrosion, oxidation, and moisture penetration, ensuring the paint remains in its optimal condition for an extended period of time.

- Q: How does tinplate contribute to the efficiency of energy systems?

- Tinplate contributes to the efficiency of energy systems by providing a highly durable and corrosion-resistant material for the production of energy-efficient appliances, such as refrigerators and air conditioners. Its excellent thermal conductivity properties also aid in the efficient transfer of heat, reducing energy waste. Additionally, tinplate is widely used in the packaging of food and beverages, helping to preserve products and extend their shelf life, thus reducing food waste and energy consumption associated with production and transportation.

- Q: How does the thickness of tinplate affect its strength and durability?

- The thickness of tinplate directly influences its strength and durability. Generally, thicker tinplate tends to be stronger and more durable compared to thinner tinplate. A thicker tinplate has a higher resistance to bending, denting, or puncturing, making it less prone to damage during handling, storage, or transportation. Additionally, the increased thickness provides better protection against corrosion and extends the tinplate's lifespan. However, thicker tinplate also tends to be heavier and more expensive. Therefore, finding the right balance between thickness and cost is crucial when considering the strength and durability requirements for a specific application.

- Q: Is it necessary for the two cold rolling in the process of tinplate production, such as tempering and cold rolling (also called flatness)?

- Generally used in rolling and sheeting. The tinplate is usually below 0.2mm and needs to be subjected to 2 cold rolling. Of course depends on the thickness of the raw material.

- Q: How does tinplate perform in terms of electrical conductivity?

- Tinplate has relatively low electrical conductivity compared to other metals, making it less suitable for applications that require high conductivity such as electrical wiring.

Send your message to us

Electrical Tinplate, JIS G3303 Standard For Food Cans & Industrial Cans

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords