DR Temper Tinplate for Metal Can Making, Top Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Usage

Tinplate is widely used for making all types of containers, containing industrial usage such as paint can, oil can, aerosol cans etc., and food cans like milk powder cans, tomato paste can, dry food cans etc.

2. Quality

As a state owned company and a large tinplate supplier in China, our tinplate quality ranks 1st level in China, similar to Bao Steel, Posco etc.

3. Specification

Standard | GB/T2520, JIS G3303, DIN EN10202 |

Material | MR /SPCC |

Thickness available | 0.16-0.50MM |

Width available | 600~1050MM |

Temper grade | T1 – DR8 |

Tin coating | ordinary 2.8g/2.8g, 5.6g/5.6g and others |

Package | sea worthy export package |

Applications | Tin can for chemicals & paint cans, industrial cans, food cans |

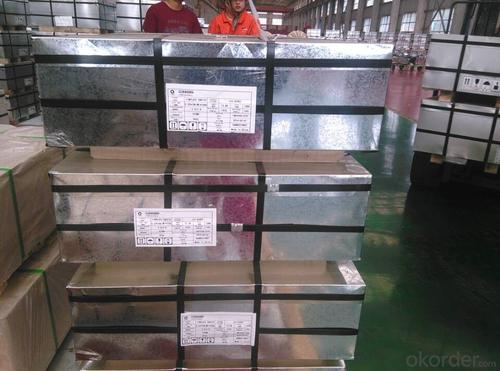

4. Our factory photo & equipments

5. Our Overseas Wareouses:

Furthermore, in the year 2014, we have more than 10 overseas warehouses all over the word, located in KSA, UAE, Oman, Russia, Kuwait, Qatar, Oman, Chile, Brazil etc.

6. FAQ

a. What’s the price difference between SPCC & MR?

Our MR is about usd 15~20/mt higher than SPCC; b. What’s the difference between SPCC & MR

They have difference element content, MR is better than SPCC in anti-rust and deep drawing.

Steel | C | Si | Mn | P | S | Cu | Others |

MR | ≤0.09 | ≤0.03 | ≤0.35 | ≤0.02 | ≤0.025 | ≤0.1 | ≤0.35 |

SPCC | ≤0.12 | ≤0.5 | ≤0.035 | ≤0.025 |

c. What production standards you accept?

We could accept production standards upon our customer request, such as JISG 3303, DIN EN10202, GB/T2520 etc. Our tinplate could meet these standards.

d. If we want to place order, is there any requirement about the booking time?

We need to purchase raw material in advance. Around date 20 per month our production plan will be finalized. So it’s better if customer could place order before date 20 per month, otherwise the delivery time will delay one month.

- Q: What are the different ways to recycle tinplate containers?

- There are several ways to recycle tinplate containers. One way is to separate the tinplate from other materials, such as plastic or paper, and then melt it down to be reused for manufacturing new tinplate products. Another method involves crushing the containers to reduce their size, which makes it easier to transport and process them at recycling facilities. Additionally, tinplate containers can be repurposed for various uses, such as storage or organization, before eventually being recycled.

- Q: How does tinplate withstand corrosion?

- Tinplate withstands corrosion due to the protective properties of tin. The tin coating acts as a barrier between the underlying steel and the surrounding environment, preventing direct contact and oxidation. Tin has excellent corrosion resistance, even in humid and acidic conditions, making tinplate a reliable and durable material for various applications.

- Q: What is the average lifespan of tinplate products?

- The average lifespan of tinplate products can vary depending on several factors, such as the quality of the tinplate used, the conditions in which the products are stored and used, and how well they are maintained. Generally, tinplate products can last for several years to a decade or more if properly cared for.

- Q: How is tinplate affected by different types of sauces and condiments?

- Tinplate is generally resistant to most sauces and condiments due to its protective coating. However, highly acidic or salty sauces may cause corrosion over time, compromising the tinplate's integrity. It is advisable to promptly clean any spills or residues to minimize potential damage.

- Q: What are the common corrosion protection methods used for tinplate?

- The common corrosion protection methods used for tinplate include electroplating with tin, applying organic coatings such as lacquers or paints, and using barrier coatings like epoxy or acrylic resins.

- Q: What is the cost of tinplate?

- The cost of tinplate varies depending on factors such as the market demand, quantity purchased, and quality specifications. It is best to check with suppliers or market sources for the current pricing.

- Q: How is tinplate used in the packaging industry?

- Tinplate is commonly used in the packaging industry due to its excellent properties such as corrosion resistance, durability, and formability. It is often used in the production of metal cans and containers for food and beverages, cosmetics, and other consumer goods. The tin coating on the steel substrate provides a protective barrier against moisture, light, and oxygen, ensuring the preservation and prolonging the shelf life of the packaged products. Tinplate is also used for decorative purposes, as it can be easily printed on, making it an ideal choice for branding and marketing.

- Q: Can tinplate packaging be used for microwaveable products?

- No, tinplate packaging should not be used for microwaveable products as it can cause sparks and potential fire hazards.

- Q: How is tinplate tested for quality control?

- Tinplate is tested for quality control through various methods including visual inspection, measurement of coating thickness, adhesion testing, and corrosion resistance testing.

- Q: What are the main challenges in the production of tinplate?

- The main challenges in the production of tinplate include ensuring a consistent quality of tin coating on the steel substrate, controlling the thickness of the tin layer, preventing contamination during the production process, managing the formation of tin oxide, and minimizing the occurrence of defects such as pinholes or scratches on the tinplate surface. Additionally, maintaining a stable and efficient production line, optimizing energy consumption, and complying with environmental regulations are also significant challenges.

Send your message to us

DR Temper Tinplate for Metal Can Making, Top Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords