All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the different printing methods suitable for electrolytic tinplate sheet?

The different printing methods suitable for electrolytic tinplate sheet include lithography, flexography, and screen printing. Lithography is ideal for high-quality prints with fine details, while flexography is commonly used for large-scale production with high-speed printing. Screen printing is suitable for designs with special effects or thick ink deposits.

What types of electrical components can be made from electrolytic tinplate sheet?

Electrolytic tinplate sheet can be used to create various electrical components such as capacitors, inductors, transformers, and printed circuit boards (PCBs).

How does the tin coating on electrolytic tinplate sheet affect its resistance to moisture?

The tin coating on electrolytic tinplate sheet significantly enhances its resistance to moisture. The tin acts as a protective barrier, preventing direct contact between the metal substrate and moisture. This barrier prevents moisture from corroding the tinplate and ultimately extends its lifespan. Additionally, the tin coating provides an impermeable layer, making the tinplate sheet more resistant to moisture absorption. As a result, the tin coating plays a crucial role in preserving the integrity and durability of the tinplate sheet, even in high-humidity environments.

Wholesale Electrolytic Tinplate Sheet from supplier in Austria

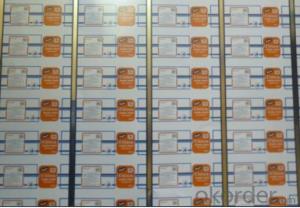

Whether you are in the packaging, automotive, or construction industry, our Electrolytic Tinplate Sheets are the ideal choice for your applications. They are known for their excellent corrosion resistance, formability, and weldability, making them suitable for various purposes.

We understand the importance of timely delivery and cost-effectiveness, which is why we have established a strong supply chain network in Austria. This enables us to efficiently handle your orders and ensure on-time delivery of the products. Our team of dedicated professionals is always ready to assist you with any queries or concerns you may have.

In addition to our sales and customer support services, we also provide technical support to help you make informed decisions regarding the use of our products. Our technical experts are well-versed in the specifications and applications of Electrolytic Tinplate Sheets, and they can guide you in choosing the right product for your specific requirements.

As a subsidiary of CNBM, we are backed by the resources and expertise of a Fortune Global 500 company. This allows us to offer competitive pricing and superior quality products to our customers in Austria. We continuously strive to exceed your expectations and ensure your satisfaction with our products and services.

Contact us today to discuss your requirements for Electrolytic Tinplate Sheets in Austria. Let us be your trusted partner for all your procurement needs, and together, we can achieve success in your projects.

We understand the importance of timely delivery and cost-effectiveness, which is why we have established a strong supply chain network in Austria. This enables us to efficiently handle your orders and ensure on-time delivery of the products. Our team of dedicated professionals is always ready to assist you with any queries or concerns you may have.

In addition to our sales and customer support services, we also provide technical support to help you make informed decisions regarding the use of our products. Our technical experts are well-versed in the specifications and applications of Electrolytic Tinplate Sheets, and they can guide you in choosing the right product for your specific requirements.

As a subsidiary of CNBM, we are backed by the resources and expertise of a Fortune Global 500 company. This allows us to offer competitive pricing and superior quality products to our customers in Austria. We continuously strive to exceed your expectations and ensure your satisfaction with our products and services.

Contact us today to discuss your requirements for Electrolytic Tinplate Sheets in Austria. Let us be your trusted partner for all your procurement needs, and together, we can achieve success in your projects.