Tinplate Metal

Tinplate Metal Related Searches

Tinplate Iron Tinplate Material Tinplate Factory Tinplate Studios Printed Tinplate Tinplate Market Tinplate Production Tinplate Box Tinplate Future Tinplate Uk Tinplate Submarine Tinplate Products Marx Tinplate Tinplate Printing Tinplate Coating Tinplate Printing Machine Tinplate Company Tinplate China Tinplate Forum Tinplate Can Tinplate Bucket Tinplate Share Tinplate Recycling Tinplate Goldfish Lacquered Tinplate Tinplate Cover Tata Tinplate Italy Tinplate Tinplate Packaging Tinplate ProducersTinplate Metal Supplier & Manufacturer from China

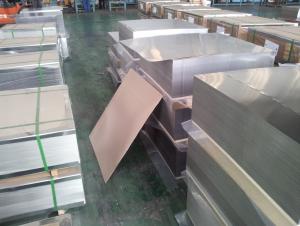

Tinplate Metal is a type of steel sheet coated with a thin layer of tin, which provides excellent corrosion resistance and enhances its appearance. This material is widely recognized for its durability and versatility, making it an ideal choice for various applications. The product's unique properties make it suitable for a range of uses, such as in the manufacturing of food cans, beverage cans, and other packaging materials. Additionally, it is utilized in the automotive, construction, and electronics industries due to its strength and resistance to corrosion. Okorder.com is a leading wholesale supplier of Tinplate Metal, offering a vast inventory to cater to the needs of various industries. With a commitment to quality and customer satisfaction, Okorder.com ensures that Tinplate Metal is readily available for businesses looking to incorporate this versatile material into their products.Hot Products