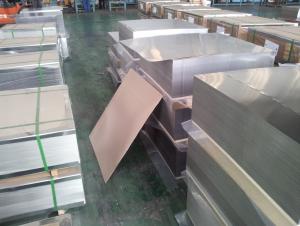

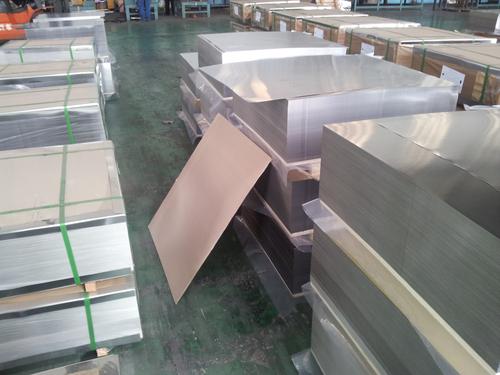

Tinplate for Metal container

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Our Tinplates Specification is as below:

Standard: ISO 11949 -1995, JIS G3303,ASTM A623, BS EN 10202

Material: MR,SPCC

Thickness:0.15mm - 0.50mm

Width and Length: 600mm -1150mm

Temper: T1-T5

Annealing: BA & CA

Tincoating:customized

Both Prime and Secondary Quality are available!!!

- Q: How does tinplate affect the overall product freshness?

- Tinplate plays a significant role in preserving the overall product freshness. Its unique properties, such as excellent barrier properties against light, oxygen, and moisture, help in extending the shelf life of the contents inside the tinplate packaging. This prevents oxidation, spoilage, and contamination, ensuring that the product remains fresh and retains its quality for a longer period of time.

- Q: How is tinplate used in the manufacturing of electronic devices?

- Tinplate is commonly used in the manufacturing of electronic devices for its corrosion resistance and excellent conductivity. It is often utilized as a coating material for printed circuit boards (PCBs) to protect them from oxidation and enhance their durability. Additionally, tinplate is utilized in the production of connectors, switches, and other electrical components due to its ability to facilitate smooth electrical flow and ensure reliable performance.

- Q: What kind of material is tinplate?

- Tin plate is tin plated steel, that is iron.

- Q: How does tinplate perform in terms of light protection?

- Tinplate performs well in terms of light protection due to its opaque nature, which helps to block out light and prevent the entry of harmful UV rays.

- Q: What are the main applications of tinplate in the electrical industry?

- Tinplate is widely used in the electrical industry for various applications such as manufacturing of electrical enclosures, switchgear cabinets, and transformer cores. Its corrosion-resistant properties make it an ideal material for protecting electrical components from environmental factors. Additionally, tinplate is often utilized for the production of electrical connectors and terminals due to its excellent conductivity and solderability.

- Q: How is tinplate coated for construction materials?

- Tinplate is coated for construction materials through a process called electrolytic tinning. This involves immersing the steel sheet in an electrolyte bath and passing an electric current through it. The electric current causes tin ions to be reduced and deposited onto the steel surface, forming a thin layer of tin coating. This coating provides corrosion resistance and enhances the durability of the construction materials.

- Q: What are the main challenges in tinplate manufacturing?

- Some of the main challenges in tinplate manufacturing include ensuring consistent quality of the tin coating, maintaining precise thickness and uniformity of the tinplate, managing the handling and storage of the tinplate to prevent damage or contamination, and addressing environmental concerns related to the tin coating process and waste disposal. Additionally, the industry faces the challenge of meeting customer demands for cost-effective production while adhering to strict regulatory standards and keeping up with technological advancements.

- Q: Can tinplate be embossed or engraved?

- Yes, tinplate can be embossed or engraved.

- Q: How does tinplate handle extreme weather conditions?

- Tinplate is highly resistant to extreme weather conditions due to its durable and corrosion-resistant nature. It can withstand high temperatures, heavy rain, snow, and intense sunlight without warping or deteriorating. Hence, it is an excellent choice for various outdoor applications, including roofing, construction, and packaging, providing long-lasting protection even in harsh weather conditions.

- Q: What are the main challenges in the tinplate industry?

- The main challenges in the tinplate industry include fluctuating raw material prices, increasing competition from alternative packaging materials, environmental concerns related to tin coating and waste management, and the need for continuous technological advancements to meet evolving customer demands. Additionally, market volatility, trade barriers, and regulatory compliance are also key challenges faced by the tinplate industry.

Send your message to us

Tinplate for Metal container

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords