Electrolytic Tinplate of High Quality for Metal Container 0.195mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Electrolytic Tinplate of High Quality for Metal Container 0.195mm Description

Electrolytic Tinplate is a thin steel sheet coated by tin. It has an extremely beautiful metallic luster as well as excellent properties in corrosion resistance, solder ability, and weld ability.

2.Main Features of the Electrolytic Tinplate of High Quality for Metal Container 0.195mm

Electrolytic Tinplate undoubtedly enjoys the pride of place as a packaging medium especially for food. It owes its unique position to its "nine layer sandwich structure", each of which contributes to its eminence as a packing material. The steel base of electrolytic tinplate provides the necessary strength and formability for can fabrication. The tin-iron alloy layer provides the bond between the steel and free tin layer. The free tin layer is not only responsible for the attractive bright finish and ease of solderability but is also non-toxic- a factor of vital importance in food packaging!

Tinplate is also widely used for making all types of containers such as food cans, beverage cans, and artistic cans, tea cans, painting cans, chemical package cans and dry food package cans, metal printing etc. Its applications are not limited to containers; recently, electrolytic tinplate has also been used for making electrical machinery parts and many other products.

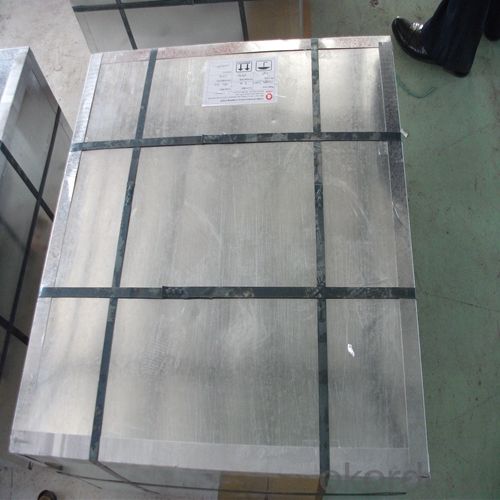

3.Electrolytic Tinplate of High Quality for Metal Container 0.195mm Images

4.Electrolytic Tinplate of High Quality for Metal Container 0.195mm Specification

Standard:BS EN 10202

Material: SPCC

Thickness:0.195mm

Width:700mm

Temper: T4

Annealing: CA

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil

Passivation:311

Oil: DOS

Surface: silver

5.FAQ of Electrolytic Tinplate of High Quality for Metal Container 0.195mm

1. What is the delivery time for your prime quality tinplate?

Usually 35 days after order confirmation.

2. What is your Minimum Order Quantity?

Usually MOQ is 50tons for one single size, for trial order, it can be 25 tons.

3. What is the payment term?

The most common we use is L/C at sight or TT. We can also try use other terms.

- Q: How does tinplate perform in terms of resistance to mechanical stress?

- Tinplate performs well in terms of resistance to mechanical stress due to its high tensile strength and durability. It can withstand bending, twisting, and impacts without significant deformation or damage.

- Q: Can tinplate be used for signage and advertising purposes?

- Yes, tinplate can be used for signage and advertising purposes. Tinplate is a versatile material that can be easily shaped, printed on, and customized to create attractive and durable signs and advertising displays. It offers a glossy finish and excellent weather resistance, making it suitable for both indoor and outdoor applications. Additionally, tinplate is cost-effective and can be recycled, making it a sustainable choice for signage and advertising needs.

- Q: What are the main applications of tinplate in the pharmaceutical industry?

- Tinplate is commonly used in the pharmaceutical industry for packaging purposes. It serves as a reliable and durable material for manufacturing cans, containers, or closures for various pharmaceutical products. Tinplate provides an effective barrier against moisture, light, and oxygen, helping to preserve the integrity, stability, and shelf life of pharmaceutical drugs. Additionally, tinplate's resistance to corrosion ensures the safety and quality of the packaged medications.

- Q: What are the different types of tinplate containers available?

- There are several types of tinplate containers available, including cans, tins, drums, and pails. These containers can vary in size, shape, and design to suit different purposes and industries.

- Q: What are the common misconceptions about tinplate packaging?

- One common misconception about tinplate packaging is that it is easily dented or damaged. In reality, tinplate is quite durable and can withstand rough handling without losing its structural integrity. Another misconception is that tinplate packaging is not environmentally friendly. However, tinplate is highly recyclable and can be reused multiple times, making it a sustainable packaging option.

- Q: How is tinplate priced?

- Tinplate is typically priced based on various factors including market demand, production costs, and quality of the tin coating. Additionally, market fluctuations and trade policies can also affect the pricing of tinplate.

- Q: How does tinplate packaging impact brand image and perception?

- Tinplate packaging can have a positive impact on brand image and perception. It is often associated with high quality and premium products, which can enhance the perceived value of the brand. Tinplate packaging also offers a luxurious and retro charm, appealing to consumers who value aesthetics and nostalgia. Additionally, tinplate packaging can provide better protection for products, ensuring their freshness and quality, which further enhances the brand's reputation. Overall, tinplate packaging can contribute to a positive brand image and create a favorable perception among consumers.

- Q: What are the benefits of using tinplate for paint cans?

- One of the main benefits of using tinplate for paint cans is its exceptional durability and resistance to corrosion. Tinplate is a coated steel material that provides a protective barrier against moisture, preventing rusting and extending the lifespan of the paint cans. Additionally, tinplate is a lightweight material, making it easy to handle and transport. It also offers excellent recyclability, making it an environmentally-friendly choice.

- Q: What are the health and safety concerns associated with tinplate?

- Some health and safety concerns associated with tinplate include potential exposure to tin and other metals, which may lead to respiratory issues if inhaled. There may also be concerns related to the use of certain coatings or paints on tinplate, which could contain harmful chemicals. Additionally, handling sharp edges or cuts from tinplate can pose a safety risk.

- Q: How is tinplate coated for pharmaceutical packaging?

- Tinplate is coated for pharmaceutical packaging by applying a thin layer of protective lacquer or enamel onto the surface. This coating acts as a barrier, preventing direct contact between the metal and the pharmaceutical product, ensuring its safety and integrity.

Send your message to us

Electrolytic Tinplate of High Quality for Metal Container 0.195mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords