All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

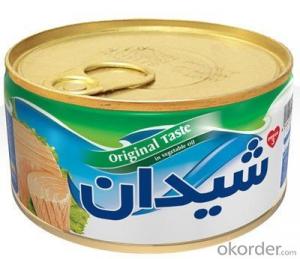

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

Can electrolytic tinplate sheet be formed or shaped easily?

Yes, electrolytic tinplate sheet can be easily formed or shaped due to its malleability and ductility.

What are the different surface treatments available for electrolytic tinplate sheet to improve adhesion of varnish coatings?

There are several surface treatments available for electrolytic tinplate sheet to enhance adhesion of varnish coatings. Some common options include chemical treatments like chromating or passivation, which create a thin layer on the surface to improve adhesion. Additionally, mechanical treatments like abrasive brushing or sanding can be used to roughen the surface and promote better adhesion.

How is the tin coating on electrolytic tinplate sheet protected during transportation and storage?

The tin coating on electrolytic tinplate sheet is protected during transportation and storage through various methods. One common way is by applying a protective lacquer or oil coating on the tin surface, which creates a barrier against external elements such as moisture, air, and corrosive substances. This protective layer helps prevent oxidation and maintain the integrity of the tin coating. Additionally, the tinplate sheets are often packed in protective packaging materials such as plastic films or wraps, ensuring further protection from physical damage, scratches, and contamination. Proper handling, storage in controlled environments, and avoiding exposure to extreme temperatures or humidity are also essential in safeguarding the tin coating during transportation and storage.

Wholesale Electrolytic Tinplate Sheet from supplier in Finland

Whether you are in the food packaging, beverage, or general manufacturing industry, our Electrolytic Tinplate Sheets are designed to meet the highest quality standards. We offer a wide range of sizes, thicknesses, and coatings to suit your specific requirements.

Our team of experienced professionals is dedicated to providing exceptional customer service. From assisting with product selection to providing technical support, we are committed to ensuring your satisfaction. We understand the importance of timely delivery, and our efficient logistics network allows us to deliver your orders promptly.

As a subsidiary of CNBM, we have access to a vast global network of suppliers and resources. This enables us to offer competitive pricing and ensure a stable supply chain for our customers. Our strong relationship with CNBM also provides us with the latest industry trends and innovations, allowing us to continuously improve our product offerings.

At our company, we prioritize sustainability and environmental responsibility. Our Electrolytic Tinplate Sheets are produced using eco-friendly processes, and we strive to minimize waste and energy consumption throughout our operations.

We value long-term partnerships with our customers and aim to be your trusted supplier for all your Electrolytic Tinplate Sheet needs in Finland. Contact us today for a personalized consultation and let us assist you in finding the perfect solution for your projects.

Our team of experienced professionals is dedicated to providing exceptional customer service. From assisting with product selection to providing technical support, we are committed to ensuring your satisfaction. We understand the importance of timely delivery, and our efficient logistics network allows us to deliver your orders promptly.

As a subsidiary of CNBM, we have access to a vast global network of suppliers and resources. This enables us to offer competitive pricing and ensure a stable supply chain for our customers. Our strong relationship with CNBM also provides us with the latest industry trends and innovations, allowing us to continuously improve our product offerings.

At our company, we prioritize sustainability and environmental responsibility. Our Electrolytic Tinplate Sheets are produced using eco-friendly processes, and we strive to minimize waste and energy consumption throughout our operations.

We value long-term partnerships with our customers and aim to be your trusted supplier for all your Electrolytic Tinplate Sheet needs in Finland. Contact us today for a personalized consultation and let us assist you in finding the perfect solution for your projects.