All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the considerations when using hollow steel tubes in corrosive marine structures, such as offshore platforms?

When using hollow steel tubes in corrosive marine structures, such as offshore platforms, there are several important considerations to keep in mind.

Firstly, the material composition of the steel tubes should be carefully chosen to ensure high resistance to corrosion. Stainless steel or corrosion-resistant alloys are commonly used in such environments.

Secondly, it is essential to implement effective corrosion protection measures to prevent degradation of the steel tubes. This can involve applying protective coatings or using sacrificial anodes to divert corrosion away from the tubes.

Thirdly, regular inspections and maintenance are crucial to detect and address any signs of corrosion or damage promptly. This includes monitoring the integrity of the tubes, checking for any signs of pitting or cracking, and conducting routine maintenance work such as cleaning and repainting.

Additionally, the design of the offshore platform should consider factors such as exposure to saltwater, wave action, and tidal forces. Adequate structural support, anchoring, and reinforcement should be incorporated to ensure the stability and durability of the hollow steel tubes.

Overall, careful material selection, corrosion protection, regular maintenance, and robust design considerations are essential when utilizing hollow steel tubes in corrosive marine structures like offshore platforms.

How do hollow steel tubes perform in extreme weather conditions?

Hollow steel tubes are known for their durability and strength, making them perform well in extreme weather conditions. Due to their hollow design, they are resistant to deformation, cracking, and buckling, making them suitable for withstanding high winds, heavy rain, and even extreme temperatures. Additionally, steel has excellent corrosion resistance properties, enabling it to resist the effects of moisture, salt, and other environmental factors. Overall, hollow steel tubes are a reliable choice for structures or applications that require resilience in extreme weather conditions.

How do hollow steel tubes fare against other materials like aluminum or plastic?

Hollow steel tubes generally offer superior strength and durability compared to aluminum or plastic. Steel tubes have high tensile strength, making them suitable for heavy-duty applications where structural integrity is crucial. They can withstand greater pressure, impacts, and harsh environments. While aluminum tubes are lighter, they are not as strong as steel and may be more prone to bending or denting. Plastic tubes, on the other hand, are lightweight but lack the strength and rigidity of steel. However, the choice between these materials depends on specific requirements such as weight, cost, and corrosion resistance.

Can hollow steel tubes be used for staircase or railing systems?

Yes, hollow steel tubes can be used for staircase or railing systems. They are often preferred due to their strength, durability, and versatility in design. Additionally, hollow steel tubes can be easily manipulated and shaped to fit the specific requirements of a staircase or railing system, making them a popular choice in construction and architecture.

Are hollow steel tubes suitable for telecommunications infrastructure?

Yes, hollow steel tubes are suitable for telecommunications infrastructure. They are commonly used for supporting antennas and transmission equipment due to their high strength, durability, and ability to withstand environmental factors such as wind and weather conditions. Additionally, their hollow design allows for easy installation and maintenance of cables and wires, making them a reliable choice for telecommunications infrastructure.

Wholesale Hollow Steel Tubes from supplier in Finland

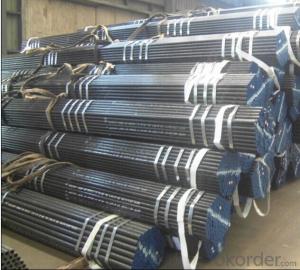

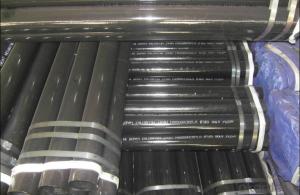

Our Hollow Steel Tubes are manufactured using high-quality materials and advanced technology, ensuring excellent durability and performance. We offer a variety of sizes, shapes, and specifications to meet the diverse needs of our customers in Finland.

In addition to our wide range of products, we also provide exceptional customer support throughout the entire process. Our dedicated sales team is available to assist you with product inquiries, provide accurate quotations, and offer technical guidance. We understand that each project is unique, and we strive to tailor our solutions to meet your specific requirements.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have the resources and capabilities to provide convenient one-stop procurement services. This means that you can rely on us for all your Hollow Steel Tube needs, from sourcing to delivery. Our efficient supply chain management ensures timely delivery to your location in Finland.

Furthermore, our extensive experience in the Finnish market sets us apart from our competitors. We have established strong relationships with local suppliers and have a deep understanding of the industry dynamics in Finland. This knowledge allows us to provide valuable insights and recommendations to optimize your projects.

Whether you are in the construction, manufacturing, or any other industry requiring Hollow Steel Tubes in Finland, we are confident that our products and services will meet your expectations. Contact us today to discuss your requirements and let us help you achieve your project goals.

In addition to our wide range of products, we also provide exceptional customer support throughout the entire process. Our dedicated sales team is available to assist you with product inquiries, provide accurate quotations, and offer technical guidance. We understand that each project is unique, and we strive to tailor our solutions to meet your specific requirements.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have the resources and capabilities to provide convenient one-stop procurement services. This means that you can rely on us for all your Hollow Steel Tube needs, from sourcing to delivery. Our efficient supply chain management ensures timely delivery to your location in Finland.

Furthermore, our extensive experience in the Finnish market sets us apart from our competitors. We have established strong relationships with local suppliers and have a deep understanding of the industry dynamics in Finland. This knowledge allows us to provide valuable insights and recommendations to optimize your projects.

Whether you are in the construction, manufacturing, or any other industry requiring Hollow Steel Tubes in Finland, we are confident that our products and services will meet your expectations. Contact us today to discuss your requirements and let us help you achieve your project goals.