Tinplate Conyers

Tinplate Conyers Related Searches

Tinplate Tins Tinplate Containers Tinplate Coating Tinplate Cans Tinplate Iron Tinplate Material Printed Tinplate Tinplate Lids Tinplate Products Tinplate China Tinplate Printing Tinplate Pails Tinplate Share Tinplate Packaging Envases Tinplate Printing Tinplate Tinplate Food Packaging Lacquered Tinplate Tinplate Production Tinplate Manufacturers Tinplate Factory Tinplate Can Tinplate Uk Tinplate Metal Turkey Tinplate Tinplate Recycling Tinplate Producers Buy Tinplate Tinplate Company Tinplate SuppliersTinplate Conyers Supplier & Manufacturer from China

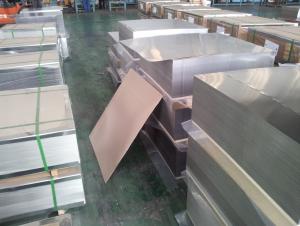

Tinplate Conyers refers to a range of tin-coated steel sheets that are widely used in various industries for their durability and corrosion resistance. These products are known for their excellent formability and weldability, making them ideal for applications in the packaging, automotive, and construction sectors. Tinplate Conyers products are utilized in the manufacturing of food and beverage cans, automotive parts, and construction materials, among other items, due to their ability to provide a protective barrier against environmental factors.The versatility of Tinplate Conyers makes it a popular choice for numerous applications and usage scenarios. In the packaging industry, it is used to create cans and containers that protect food and beverages from spoilage and contamination. In the automotive sector, it is employed in the production of various components, such as fuel tanks and exhaust systems, where its corrosion resistance is particularly beneficial. Additionally, in construction, Tinplate Conyers is used for roofing and cladding, providing a durable and weather-resistant material that can withstand harsh conditions.

Okorder.com is a leading wholesale supplier of Tinplate Conyers, offering a vast inventory of this product to cater to the needs of various industries. With a commitment to quality and customer satisfaction, Okorder.com ensures that the Tinplate Conyers they provide meet the highest standards of performance and reliability. Their extensive inventory allows customers to find the right product for their specific requirements, making Okorder.com a trusted source for Tinplate Conyers and related materials.

Hot Products