Printing Tinplate Coils With Prime Quality for 0.23mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Printing Tinplate Coils With Prime Quality for 0.23mm

1.Structure of Description

Printing Tinplate Coils With Prime Quality for 0.23mm is one of the metal packing materials, which is widely used for making painting cans ,chemical package cans , electrical cable ,battery and metal printing etc.

2. Main Features

Steady and high quality

Fast shipment

Good experience for export work

For the surface, Plate uniform in thickness,uniform and smooth tin coating, without flaws,rusts,scratch,wave,nick of tin coating etc.

Price competitive

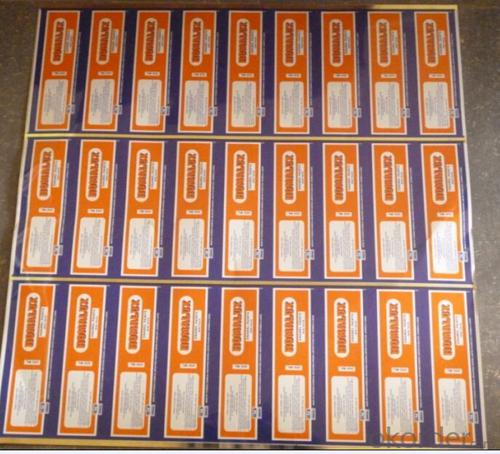

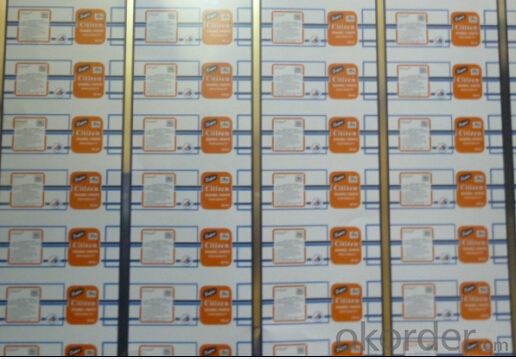

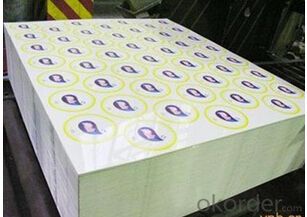

3. Images

4. Specification

Standard : GB2520-2000 ,JIS G3303

Steel type : SPCC

Coating : 2.8/2.8

Surface: Bright, Stone ,

Thickness:0.31

Width :600MM~1000MM

Temper : T1~T5

Package: tinplate wrapped completely with an inner cover of plastic or waterproof papers with vorners protected with metal angels.

5.FAQ

A. What is the package of tinplate? (Referred as below)

For sheets, thin plastic film + rust-proof paper + metallic cover + metallic angles+ steel band strips + fumigated wooden pallet.

For coil, thin plastic film + rust proof paper + metallic cover + steel band strips + fumigated wooden pallet

B. The surface of tinplate could you supply?

Stone finish, Bright finish, Matte finish, Silver finish

C. What quantity is the minimum order of tinplate?

Usually, the minimum quantity is 25MT. For special case, consult with us.

D. Can it make to be BA or CA for annealing?

Yes, both can do with.

- Q: What are the regulations regarding tinplate packaging?

- The regulations regarding tinplate packaging vary depending on the country and the specific product being packaged. However, some common regulations include restrictions on the use of certain chemicals in the coating of tinplate, requirements for labeling and product information, and guidelines for food safety and hygiene. It is important for manufacturers and distributors to familiarize themselves with the specific regulations in their target market to ensure compliance.

- Q: What are the different ways to store tinplate containers?

- There are several ways to store tinplate containers, depending on the available space and the specific needs of the items being stored. Some common storage methods include stacking the containers on shelves or pallets, placing them in storage bins or crates, hanging them on hooks or racks, or arranging them in storage cabinets or drawers. The chosen method should ensure easy access, proper organization, and minimal risk of damage to the containers.

- Q: What are the different ways to recycle tinplate containers?

- There are several different ways to recycle tinplate containers. One common method is to bring them to a local recycling center where they can be sorted and processed for recycling. These containers are typically made of steel or aluminum, which can be melted down and used to create new products. Another option is to reuse tinplate containers for storage or other purposes before eventually recycling them. Additionally, some communities offer curbside recycling programs where tinplate containers can be collected alongside other recyclable materials.

- Q: What are the considerations for handling and storing tinplate coils?

- There are several considerations for handling and storing tinplate coils. Firstly, it is important to handle the coils with care to prevent any damage or deformation. This includes using appropriate lifting equipment, avoiding dropping or dragging the coils, and ensuring a smooth and controlled transfer process. Secondly, the storage environment should be suitable for tinplate coils. They should be stored in a clean, dry, and well-ventilated area to prevent corrosion and rusting. It is recommended to keep the coils away from direct sunlight, extreme temperatures, and moisture. Additionally, proper stacking and organization of the coils is crucial. They should be stacked on flat and stable surfaces, with adequate support and spacing between each coil. Labeling the coils with relevant information such as date of manufacture, size, and grade can aid in efficient inventory management. Lastly, regular inspections should be conducted to identify any potential issues or defects. This includes checking for any signs of corrosion, dents, or scratches that may have occurred during handling or storage. Prompt action should be taken to address any problems to ensure the quality and integrity of the tinplate coils.

- Q: Can tinplate packaging be used for aerosol products?

- Yes, tinplate packaging can be used for aerosol products. Tinplate is a commonly used material in aerosol can production due to its durability, resistance to corrosion, and ability to withstand the pressure exerted by aerosol content. Additionally, tinplate cans can be easily shaped and decorated, making them suitable for various aerosol products in the market.

- Q: How does tinplate perform in terms of oxygen barrier properties?

- Tinplate performs excellently in terms of oxygen barrier properties. The tin coating on the steel substrate acts as an effective barrier, preventing oxygen from permeating through the material. This property makes tinplate ideal for packaging applications, as it helps to preserve the freshness and quality of oxygen-sensitive products.

- Q: How does tinplate perform in terms of magnetic properties?

- Tinplate exhibits poor magnetic properties as it is a non-magnetic material.

- Q: What are the common quality standards for tinplate?

- The common quality standards for tinplate include factors such as the thickness and uniformity of the tin coating, the absence of defects like scratches or dents, the adhesion of the tin coating to the base metal, and the overall dimensional and mechanical properties of the tinplate.

- Q: What are the typical transportation requirements for tinplate?

- The typical transportation requirements for tinplate involve careful handling to prevent damage or denting, as well as protection from moisture to avoid rusting. Tinplate is often transported in specialized packaging or containers to ensure its safety during transit. Additionally, the transportation process should consider the weight and volume of the tinplate to determine the appropriate mode of transportation, whether it be by truck, rail, or sea.

- Q: What are the different types of tinplate coatings available?

- There are several types of tinplate coatings available, including electrolytic tinplate (ETP), tin-free steel (TFS), and lacquered tinplate. ETP is the most common type and it provides excellent corrosion resistance and a shiny appearance. TFS, on the other hand, does not contain tin and is coated with a layer of chromium or chromium oxide, offering similar corrosion resistance as ETP. Lacquered tinplate is coated with a layer of lacquer, providing additional protection against corrosion and enhancing the appearance of the tinplate.

Send your message to us

Printing Tinplate Coils With Prime Quality for 0.23mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords