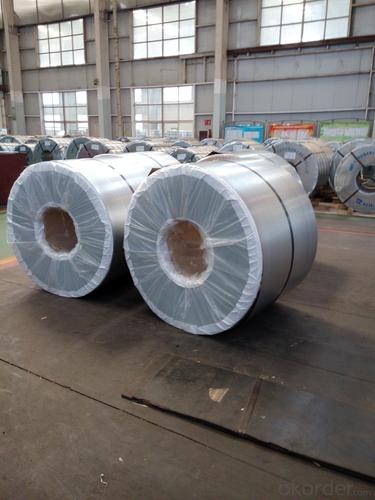

PRIME GOOD QUALITY Tinplate ETP

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We have been producing tinplate material professionally and providing related service for decades years. Now we have been exporting our material to the world. Please kindly contact us to meet your needs for ETP materail.

Below is the specification we currently do:

1. Standard: GB/T 2520-2000, JIS G3303-2002 and DIN EN 10203-1991

2. Raw material: MR, SPCC

3.Thickness: 0.18 to 0.50mm

4. Width: 260 to 980mm

5. Coil diameter: ID 420mm or 508mm

6. Temper grade: T2, T3 and T4

7. Tin coating: ordinary 2.8 or 2.8g and 5.6g or 5.6g, can produce according to customer's requests

8. Applications: paint, chemical and other usage can make battery, electric cable and other industries

9. Package: anti-rust paper, corner protected. Sheets or coils according customer's request.

Standard for Temper:

code | Chinese Stardard | Japaness Standard | American Standard | European Standard | International Standard |

| GB/T 2520-2000 | JIS G3303-2002 | ASTM A623M-2002 | DIN EN 10203-1991 | ISO 11949-1995 |

T-2 | TH52+SE | T-2 | T-2(53) | T52 | TH52+SE |

T-2.5 | TH55+SE | T-2.5 |

|

| TH55+SE |

T-3 | TH57+SE | T-3 | T-3(T57) | T57 | TH57+SE |

T-3.5 |

|

|

|

|

|

T-4 | TH61+SE | T-4 | T-4(T61) | T61 | TH61+SE |

Surface of tinplate:

Marks | Surface state | Characteristics |

B | Bright rough | Glazed surface obtained after melting treatment of electrotinned smooth raw material strip featuring certain oriented rubstone figure. |

R | Stone rough | Glazed surface obtained after melting treatment of electrotinned raw material strip featuring certain oriented rubstone figure. |

S | Silver rough | Glazed surface obtained after melting treatment of electrotinned raw material strip with rough matt surface. |

- Q: What are the challenges faced in the recycling of tinplate?

- One of the main challenges in recycling tinplate is the separation of tin from steel. Tin is a non-ferrous metal, while steel is ferrous, making it difficult to separate the two during the recycling process. Additionally, the presence of organic coatings or other contaminants on the tinplate can further complicate the separation process. Another challenge is the high energy consumption required to melt and separate the tin from the steel, which can impact the overall efficiency and sustainability of the recycling process. Finally, the collection and sorting of tinplate waste can also be a logistical challenge, as it requires proper infrastructure and coordination between households, businesses, and recycling facilities.

- Q: What are the main trends in the tinplate industry?

- The main trends in the tinplate industry include increased demand for sustainable packaging solutions, advancements in tin coating technologies, growing preference for easy-open lids, and the adoption of digitalization and automation for improved production efficiency. Additionally, there is a shift towards lightweight tinplate materials to reduce costs and enhance recyclability.

- Q: What are the main applications of tinplate in the photography industry?

- Tinplate is commonly used in the photography industry for the production of film canisters, which are used to store and protect photographic film. Its corrosion-resistant properties and ability to block out light make it an ideal material for preserving the quality of film. Additionally, tinplate is also used in the manufacturing of various photography accessories such as lens caps, lens hoods, and camera cases, providing durability and protection to photographic equipment.

- Q: How does tinplate packaging withstand extreme temperatures?

- Tinplate packaging withstands extreme temperatures due to its inherent properties such as high melting point and excellent heat conductivity. Additionally, the tin coating on the steel sheet acts as a protective barrier, preventing the metal from corroding or warping under extreme temperature conditions.

- Q: How does tinplate packaging contribute to product ease of use?

- Tinplate packaging contributes to product ease of use by providing durability and strength that ensures the product remains intact during transportation and handling. Its protective properties prevent damage, leakage, and contamination, ensuring the product inside remains fresh and safe for consumption. Additionally, tinplate packaging often includes convenient features such as easy-to-open lids, resealable options, and ergonomic designs that enhance the overall user experience and make the product more convenient to use.

- Q: Can tinplate be painted or printed on?

- Yes, tinplate can be painted or printed on.

- Q: What details should I pay attention to when purchasing tinplate packing boxes?

- Long engaged in procurement can know, when custom cans tends to care about is the first mold, mold it all if there is to say, if there is no mold that must face mold, mold cost is between the price of tin supplier are not much different from what. The key is really quantity.

- Q: What are the different methods of labeling and branding on tinplate packaging?

- There are several methods of labeling and branding on tinplate packaging, including direct printing, lithography, embossing, and labeling with adhesive labels. Direct printing involves printing the design directly onto the tinplate using ink or paint. Lithography is a high-quality printing process that involves transferring the design onto the tinplate using a series of rollers. Embossing creates raised or recessed designs on the tinplate by pressing it with a die. Lastly, labeling with adhesive labels involves applying pre-printed labels onto the tinplate surface.

- Q: Can tinplate be used for automotive applications?

- Yes, tinplate can be used for automotive applications. Tinplate is a type of steel coated with a thin layer of tin, which provides it with excellent corrosion resistance. This makes it suitable for various automotive components, such as fuel tanks, panels, and trim. Additionally, tinplate is easily formable, weldable, and has good strength, making it a favorable material for automobile manufacturing.

- Q: Can tinplate be used for petrochemical packaging?

- Yes, tinplate can be used for petrochemical packaging. Tinplate is a commonly used material in the packaging industry due to its excellent properties such as corrosion resistance, durability, and ability to preserve the quality of the contents. It is suitable for packaging various products, including petrochemicals, as it provides a protective barrier against moisture, oxygen, and other contaminants. Additionally, tinplate can be easily shaped into different forms, making it versatile for packaging different shapes and sizes of petrochemical products.

Send your message to us

PRIME GOOD QUALITY Tinplate ETP

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords