Envases Tinplate Sau

Envases Tinplate Sau Related Searches

Envases Tinplate Tinplate Packaging Tinplate Tins Tinplate Cans Nse Tinplate Printed Tinplate Tinplate Containers Tinplate Food Packaging Buy Tinplate Tinplate Coating Tinplate Products Printing Tinplate Tinplate Can Tinplate Recycling Tinplate Cover Tinplate Printing Spte Tinplate Spain Tinplate Tinplate Layout Tinplate China Lacquered Tinplate Tinplate For Sale Tinplate Share Tinplate Material Siam Tinplate Tinplate Production Thai Tinplate Printed Tinplate Sheets Tinplate Tea Set Tinplate SheetsEnvases Tinplate Sau Supplier & Manufacturer from China

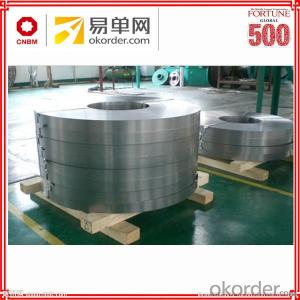

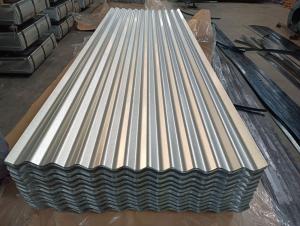

Envases Tinplate Sau offers a diverse range of tinplate packaging products, catering to various industries and consumer needs. These products are widely recognized for their durability, aesthetic appeal, and eco-friendly nature, making them a popular choice for packaging solutions. The tinplate containers from Envases Tinplate Sau are commonly used in the food and beverage industry, as well as for pharmaceutical and cosmetic products. They provide an excellent barrier against light, oxygen, and moisture, ensuring the preservation of the contents and maintaining their freshness and quality.Okorder.com is a leading wholesale supplier of Envases Tinplate Sau products, boasting a vast inventory that caters to the demands of businesses worldwide. By partnering with Okorder.com, customers can access a comprehensive selection of tinplate containers, ensuring that their packaging requirements are met with ease. The company's commitment to quality and customer satisfaction has made it a trusted source for Envases Tinplate Sau products, providing businesses with reliable and cost-effective packaging solutions.

Hot Products