Hot Rolled Steel Plate SS400 Made In China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

GRADE:

SS400, ASTM A36, A572, ST37,ST52, Q195, Q215, Q235,Q345, S235JR etc.

STANDARD:

GB/T709-2006, ASTM A36, JIS G3101, DIN EN 10025, SAE 1045, ASTM A570

SPEC:

1) Width: 600-2500mm or 1000,1050,1250,1500,1800,2000mm

2) Thickness:1.5mm-200mm or as customers’ special requirements

3) Length: 2-12m or as customers’ special requirements

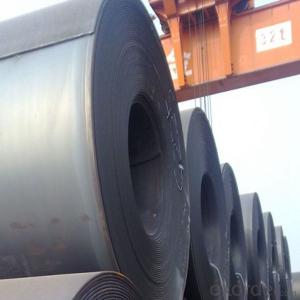

DETAILED PICTURES FOR STEEL COILS

PACKAGING &DELIVERY FOR STEEL COILS/SHEETS

Packaging Detail Standard export packing or following customer's demand

Delivery Time: Within 30-40 days after deposit or according to the order quantity

OUR SERVICE

1.High quanlity and reasonable price.

2.Customized on-demand.

3.Reasonable shipping and fast delivery.

4.Free sample.

FAQ

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: How can I get the samples?

A: If you need some samples to test ,please pay for the transportation freight of samples and our samples are free for you.

Q: How can I get your price list?

A: Please send us your email or fax and order information – Quantity, Specification (steel type, thickness, width, surface finish), then I can send you the price list.

- Q: Can the steel sheets be used for storage cabinets?

- Yes, steel sheets can be used for storage cabinets as they are durable, strong, and provide excellent protection for stored items.

- Q: Are the steel sheets suitable for automotive applications?

- Yes, steel sheets are commonly used in automotive applications due to their high strength, durability, and formability. They provide structural support, enhance crash safety, and can be easily shaped into various automotive components, making them suitable for the automotive industry.

- Q: What is the price of each steel sheet?

- The price of each steel sheet may vary depending on various factors such as size, thickness, quality, and market conditions. It is best to check with steel suppliers or manufacturers to get an accurate and up-to-date price for the specific steel sheet you are interested in purchasing.

- Q: What's the good way to connect two Q235 steel bolts? Why?

- The two scheme should be avoided by 1 reasons, is not easy to locate; 2, the mechanical strength is lower than that of Q235 steel plate bolt, bolt if 8.8 or 10.9 has no significance; 3, time is in low efficiency and tap plate fees, high production cost. Only when the space of the tightening nut is not enough can the connection mode of the steel plate upside screw thread be adopted.

- Q: What is the maximum length of steel sheets?

- The maximum length of steel sheets can vary depending on various factors such as the manufacturing process, transportation capabilities, and customer requirements. However, in general, steel sheets can range in length from a few feet to several hundred feet.

- Q: Can steel sheets be used for outdoor sculptures?

- Yes, steel sheets can be used for outdoor sculptures. Steel is a durable and weather-resistant material that can withstand outdoor conditions, making it suitable for sculptural installations in outdoor environments. Its strength and versatility allow for various creative possibilities in sculpting outdoor artworks.

- Q: What is a cold rolled sheet with plastic sprayed?

- Among them, plastic spraying is a surface treatment method of spraying plastic powder on parts. Spray is the electrostatic powder we often speak of spraying, it is the use of electrostatic generator to make plastic powder charged, adsorbed on the iron surface, then after 180 to 220 DEG C baking, the powder melting adhesion on the surface of metal, plastic products used for the indoor use of the film is flat or matte effect. Spray powder mainly has acrylic powder, polyester powder and so on.

- Q: What is the difference between a galvanized and aluminum steel sheet?

- To protect carbon steel from corrosion, a layer of zinc is applied to create a galvanized steel sheet. This process, called galvanization, involves immersing the steel in molten zinc, which forms a protective coating on the surface. Galvanized steel sheets are highly durable and act as a barrier against moisture, chemicals, and other corrosive elements. They find wide use in construction, automotive, and industrial sectors. Contrarily, aluminum steel sheets are produced from lightweight and corrosion-resistant aluminum. Rolled from aluminum ingots, these sheets come in varying thicknesses. Even without additional coatings or treatments, aluminum sheets offer exceptional resistance to corrosion. They are commonly employed in aerospace, transportation, and architectural applications. When it comes to differences, the key distinction between galvanized and aluminum steel sheets lies in their composition and protective properties. Galvanized steel sheets possess a zinc coating, which provides superior corrosion resistance compared to plain carbon steel. This makes them more suitable for outdoor and high-moisture environments. Moreover, galvanized steel sheets can be easily welded and painted, allowing for greater customization. In contrast, aluminum steel sheets have inherent corrosion resistance due to the presence of aluminum. They are lighter in weight than galvanized steel sheets, making them a preferred choice for applications that prioritize weight reduction. Aluminum sheets also exhibit better thermal conductivity and reflectivity properties, making them ideal for applications that involve heat dissipation or insulation. To summarize, galvanized steel sheets are carbon steel sheets protected by a layer of zinc to enhance corrosion resistance, while aluminum steel sheets are made from aluminum and offer inherent resistance to corrosion. The choice between galvanized and aluminum steel sheets depends on specific application requirements, such as the level of corrosion protection needed, weight considerations, and desired thermal properties.

- Q: Can steel sheets be used in telecommunications applications?

- Yes, steel sheets can be used in telecommunications applications. Steel sheets are commonly used for the fabrication of telecom cabinets, enclosures, and equipment racks. They provide durability, strength, and electromagnetic shielding properties, making them suitable for protecting telecommunications equipment and infrastructure.

- Q: Can steel sheets be used for mezzanine flooring?

- Yes, steel sheets can be used for mezzanine flooring. Steel sheets are commonly used for mezzanine flooring due to their durability, strength, and ability to support heavy loads. They provide a stable and safe platform for various applications in industrial and commercial settings.

Send your message to us

Hot Rolled Steel Plate SS400 Made In China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords