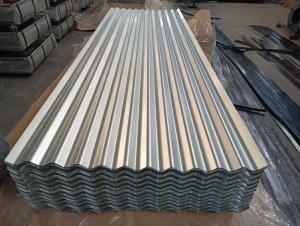

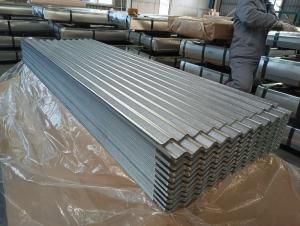

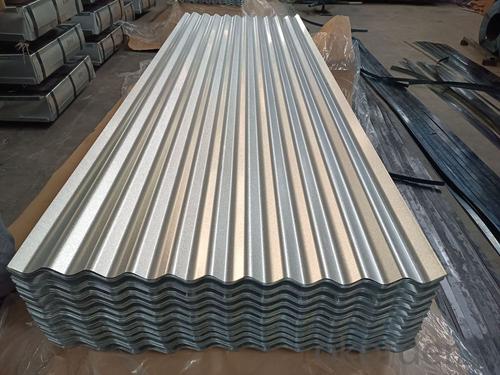

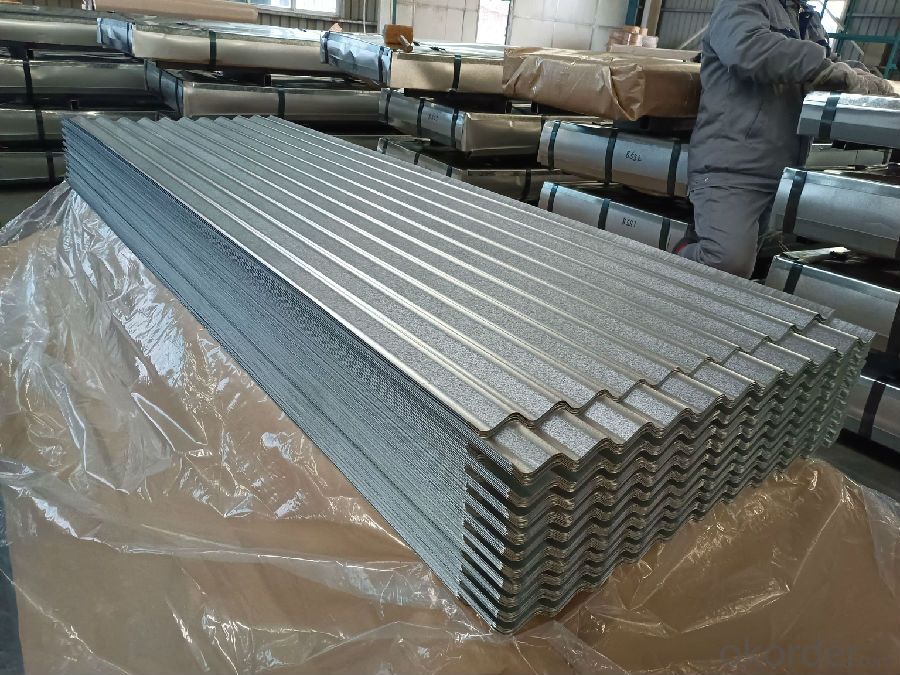

Corrugated Aluzinc Steel Sheet JIS G3321 Flat Sheet for Building & Roofing Material in Stock

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

In Stock & Fast Delivery

Steel Grade & Standard: JIS G3321

Zinc Coating Mass:AZ50g/m2 (+/-10g)

Surface Treatment: Unoiled,Chromated

0.25mm linear meter: 579m/mt 0.3mm linear meter: 481m/mt

WIDTH AFTER CORRUGATED: 800MM;

WIDTH BEFORE CORRUGARED:900MM

- Q: How do you cut a steel sheet?

- In order to cut a steel sheet, it is necessary to utilize the correct tools and techniques. The following are several commonly employed methods: 1. Power tools: An angle grinder equipped with a cutting disc is the most frequently used power tool for cutting steel sheets. While operating the grinder, it is essential to wear safety goggles and gloves. Begin by marking the cutting line on the sheet using a marker or chalk. Then, slowly and steadily maneuver the grinder along the marked line to cut through the steel. 2. Shears: For thin steel sheets, manual or electric shears can be employed. These tools possess a scissor-like cutting mechanism specifically designed for cutting metal. Position the steel sheet between the shears' blades, aligning the cutting line with them, and apply consistent pressure to cut through the sheet. 3. Plasma cutting: This technique is most suitable for thicker steel sheets. Plasma cutting involves the utilization of a high-velocity jet of ionized gas (plasma) to melt and sever the metal. Specialized equipment, such as a plasma cutter utilizing an electric arc to generate the plasma jet, is necessary for this method. 4. Waterjet cutting: Another effective method for cutting steel sheets is waterjet cutting. This method employs a high-pressure jet of water mixed with an abrasive substance, such as garnet, to cut through the metal. Although this technique is ideal for intricate shapes and precise cuts, it requires specialized machinery. Prioritizing safety is of utmost importance before attempting to cut a steel sheet. It is crucial to wear suitable protective gear, like safety glasses, gloves, and, if necessary, a face shield. Additionally, ensure that the work area is well-ventilated to prevent inhaling any fumes or particles produced during the cutting process.

- Q: Can steel sheets be used for elevator shafts or doors?

- Yes, steel sheets can be used for elevator shafts or doors. Steel is a common material used in construction due to its durability, strength, and fire resistance properties. Elevator shafts and doors often require materials that can withstand heavy loads and provide structural integrity, making steel sheets a suitable choice for these applications.

- Q: Can steel sheets be used for structural purposes?

- Yes, steel sheets can be used for structural purposes. Steel sheets are commonly used in construction and engineering projects to provide strength and support to various structures such as buildings, bridges, and infrastructure. The high tensile strength and durability of steel make it an ideal material for structural applications.

- Q: Are steel sheets resistant to humidity?

- Yes, steel sheets are generally resistant to humidity. Due to their corrosion-resistant properties, steel sheets are able to withstand exposure to high levels of moisture without significant degradation or damage. However, it is important to note that prolonged exposure to extreme humidity or harsh environmental conditions can still potentially lead to some degree of corrosion.

- Q: What are the different types of surface finishes available for steel sheets?

- There are several types of surface finishes available for steel sheets, each serving different purposes and providing distinct aesthetics. Some of the most common types include: 1. Hot rolled: This finish is achieved by heating the steel above its recrystallization temperature and then rolling it, resulting in a rough texture. It is commonly used for structural applications where aesthetics are not a primary concern. 2. Cold rolled: In contrast to hot rolled, cold rolled steel sheets are processed at room temperature, resulting in a smoother and more refined finish. This finish is often used for applications that require a higher level of precision or a more visually appealing surface. 3. Galvanized: Galvanization involves coating steel sheets with a layer of zinc, providing excellent corrosion resistance. This finish is commonly used in outdoor applications or environments with high levels of moisture. 4. Electro-galvanized: Similar to galvanized finish, electro-galvanized steel sheets are coated with a layer of zinc. However, this process involves the use of an electrical current to deposit the zinc, resulting in a thinner and more uniform coating. 5. Stainless steel: This finish is achieved by adding chromium to steel sheets, creating a protective layer that prevents corrosion and staining. Stainless steel is known for its high strength and resistance to a wide range of chemicals, making it suitable for various applications, including kitchen appliances and medical equipment. 6. Satin: This finish is characterized by a smooth and brushed appearance, achieved by using abrasive materials on the steel surface. Satin finish provides a low-reflective surface with a subtle sheen, making it commonly used for architectural and decorative purposes. 7. Mirror: As the name suggests, mirror finish steel sheets have a highly reflective surface that resembles a mirror. This finish is achieved by polishing the steel using progressively finer abrasives until a mirror-like surface is obtained. Mirror finish is often used in decorative applications, such as furniture, automotive trim, and decorative panels. 8. Painted: Steel sheets can also be coated with paint to enhance their appearance and provide additional protection against corrosion. This finish offers endless color options and customization possibilities, making it suitable for a wide range of applications. These are just a few examples of the various surface finishes available for steel sheets. The choice of finish will depend on the specific requirements of the application, including aesthetics, corrosion resistance, and functionality.

- Q: Can steel sheets be used for outdoor sculptures or artwork?

- Yes, steel sheets can be used for outdoor sculptures or artwork. Steel is a durable material that can withstand outdoor conditions and can be shaped and welded into various artistic forms. Its strength and resistance to corrosion make it suitable for outdoor installations, allowing for the creation of long-lasting and visually appealing sculptures and artwork.

- Q: Can steel sheets be recycled after use?

- Yes, steel sheets can be recycled after use. Steel is a highly recyclable material, and the recycling process involves melting down the steel sheets to create new steel products without compromising their quality. This helps conserve natural resources, reduce energy consumption, and minimize waste.

- Q: Can steel sheets be used for outdoor applications?

- Yes, steel sheets can be used for outdoor applications. Steel is a durable and weather-resistant material, making it suitable for various outdoor uses such as roofing, siding, fencing, and construction projects. It is capable of withstanding harsh weather conditions, including rain, wind, and sunlight, without significant deterioration. Additionally, steel sheets can be treated or coated to further enhance their resistance to corrosion, making them an ideal choice for outdoor applications.

- Q: Can steel sheets be used for storage racks or shelving?

- Yes, steel sheets can be used for storage racks or shelving. Steel is a strong and durable material that can support heavy loads, making it ideal for storing items in racks or on shelves. Steel sheets can be easily fabricated and customized to fit specific storage needs, providing a versatile and reliable solution for organizing and storing various items.

- Q: How do you cut steel sheets?

- Steel sheets can be cut through several methods, including using power tools such as plasma cutters, laser cutters, or shearing machines. These tools provide precise and efficient cuts by melting, burning, or shearing through the steel sheet. The choice of method often depends on the thickness and type of steel being cut, as well as the desired precision and speed.

Send your message to us

Corrugated Aluzinc Steel Sheet JIS G3321 Flat Sheet for Building & Roofing Material in Stock

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords