Electrolytic Tinplate of Good Quality for Metal Container 0.15mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Electrolytic Tinplate of Good Quality for Metal Container 0.15mm Description

Tinning is the process of thinly coating sheets of wrought iron or steel with tin, and the resulting product is known as tinplate. It is most often used to prevent rust.

2.Main Features of the Electrolytic Tinplate of Good Quality for Metal Container 0.15mm

Electrolytic Tinplate undoubtedly enjoys the pride of place as a packaging medium especially for food. It owes its unique position to its "nine layer sandwich structure", each of which contributes to its eminence as a packing material. The steel base of electrolytic tinplate provides the necessary strength and formability for can fabrication. The tin-iron alloy layer provides the bond between the steel and free tin layer. The free tin layer is not only responsible for the attractive bright finish and ease of solderability but is also non-toxic- a factor of vital importance in food packaging!

Tinplate is also widely used for making all types of containers such as food cans, beverage cans, and artistic cans, tea cans, painting cans, chemical package cans and dry food package cans, metal printing etc. Its applications are not limited to containers; recently, electrolytic tinplate has also been used for making electrical machinery parts and many other products.

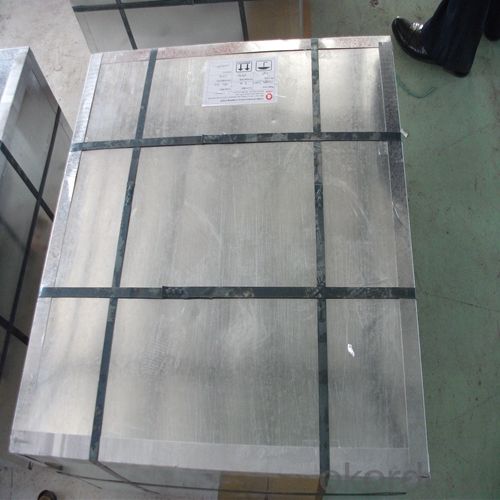

3.Electrolytic Tinplate of Good Quality for Metal Container 0.15mm Images

4.Electrolytic Tinplate of Good Quality for Metal Container 0.15mm Specification

Reference standard: GB2520-88, JIS G3303-1997 and DIN EN10203-91

Material: MR,

Thickness : 0.15mm to 0.45mm

Width available: 600mm to 980mm

Temper grade: T1 - T5 BA and CA both.

Tin coating: ordinary 2.8g/2.8g, 5.6g/5.6g, We also can produce according to customers' requests

Coil diameter: ID 420/ 508mm, OD from 1,000 to 1,250mm

Package: Anti-rust paper,corner protected. by sheet or coils according customer's require.

Applications: metal package usage like paint, chemical can,aerosol can and different food can production,

Also battery,electric cable and other industries

5.FAQ of Electrolytic Tinplate of Good Quality for Metal Container 0.15mm

1. What is the delivery time for your prime quality tinplate?

Usually 35~40 days after order confirmation.

2. What is your Minimum Order Quantity?

Usually MOQ is 50tons for one single size, for trial order, it can be 25 tons.

3. What is the payment term?

The most common we use is L/C at sight or TT. We can also try use other terms.

- Q: How does tinplate affect the overall product freshness?

- Tinplate packaging helps to preserve the overall product freshness by providing a protective barrier against moisture, light, and oxygen. This prevents the product from spoiling or deteriorating quickly, allowing it to maintain its quality and freshness for a longer period of time.

- Q: What are the typical cost considerations for tinplate packaging?

- The typical cost considerations for tinplate packaging include the cost of the raw materials, such as tinplate sheets, coatings, and inks, as well as the cost of manufacturing processes, such as cutting, printing, and shaping. Other factors that can impact costs include the size and complexity of the packaging design, the volume of production, transportation costs, and any additional features or customization required. Additionally, factors like market demand, competition, and economies of scale can also influence the overall cost of tinplate packaging.

- Q: What are the regulations regarding the use of tinplate in food packaging?

- The regulations regarding the use of tinplate in food packaging vary by country. In the United States, the Food and Drug Administration (FDA) regulates the use of tinplate in food packaging materials. Tinplate must comply with the FDA's requirements for food contact substances, ensuring that it is safe and does not transfer harmful substances to the food. Additionally, there may be specific regulations and standards set by other countries or regions, so it's important to consider the specific jurisdiction when determining the regulations for tinplate use in food packaging.

- Q: How does tinplate contribute to the conductivity of electrical components?

- Tinplate contributes to the conductivity of electrical components by providing a thin layer of tin coating on the surface, which enhances the flow of electric current and reduces resistance. This tin coating acts as a protective barrier against corrosion, ensuring long-term conductivity and preventing the electrical components from deteriorating over time.

- Q: How to test the tightness of tin metal cans?

- The empty tank which has been cleaned can be dried by 35, and the pressure or pressure leak test shall be carried out according to the equipment condition of each unit. B.1 pressure leak test, the empty tank will be carefully injected into the water until eight or nine into full, the rubber ring will be placed in the appropriate plexiglass plate at the opening side of the roll, so that it can be sealed. Start the vacuum pump, turn off the bleeder valve, hold down the cover by hand, control the pumping, and make the vacuum gauge rise from 0Pa to 6.8X10 PA (510mmHg) for more than 1min, and keep the vacuum above 1min.

- Q: How does tinplate perform in terms of impact resistance?

- Tinplate demonstrates good impact resistance due to its inherent strength and durability. It can withstand moderate impact without denting or deforming easily, making it suitable for various packaging and industrial applications.

- Q: What are the safety regulations for using tinplate in toys?

- The safety regulations for using tinplate in toys typically involve compliance with relevant international safety standards. These regulations ensure that the tinplate used in toys is free from hazardous materials, such as lead or other toxic substances, and that it meets specific safety requirements, such as resistance to sharp edges or choking hazards. Compliance with these regulations aims to protect children from potential harm or injury while playing with tinplate toys.

- Q: How is tinplate used in the manufacturing of kitchenware?

- Tinplate is commonly used in the manufacturing of kitchenware as it provides a protective coating on steel products, preventing corrosion and extending their lifespan. This coating of tin also enhances the appearance of kitchenware, making it more visually appealing. Additionally, tinplate offers a non-reactive surface, ensuring that food does not get contaminated by the metal it comes in contact with. Therefore, tinplate is widely utilized for various kitchenware items like cans, containers, cookware, and utensils.

- Q: What are the common challenges in recycling tinplate packaging?

- Some common challenges in recycling tinplate packaging include contamination from other materials, such as paper or plastic, which can make the recycling process more difficult and less efficient. Additionally, tinplate packaging often contains a plastic lining or coating, which must be removed before recycling the tinplate itself. Another challenge is that tinplate packaging is often small and lightweight, making it more prone to being lost or mixed in with other waste streams. Finally, there may be limited infrastructure or collection systems in place to effectively collect and recycle tinplate packaging.

- Q: Can tinplate be used for packaging soups and broths?

- Yes, tinplate can be used for packaging soups and broths. Tinplate is a commonly used material for food packaging due to its excellent barrier properties, which help preserve the quality and freshness of the contents. It is also resistant to corrosion and can withstand high temperatures, making it suitable for packaging hot soups and broths.

Send your message to us

Electrolytic Tinplate of Good Quality for Metal Container 0.15mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords