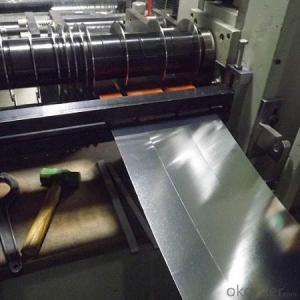

Tinplate with Prime Quality and Competitive Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Tinplate for Food Pakcaging and Chemical Packaging

Specifications

Prime electrical tinplate:

Thickness: 0.15 to 0.50mm

Width: 600 to 1010mm

Temper grade: BA and CA

For metal packaging usage

The Tinplate specification as following:

1, Reference standard: GB2520-88, JIS G3303-1997 and DIN EN10203-91

2, Material: MR, SPCC

3, Thickness available: 0.15mm to 0.50mm

4, Width available: 600mm to 1010 mm

5, Temper grade: T1 - T5 BA and CA both.

6, Tin coating: ordinary 2.8g/2.8g, 5.6g/5.6g, We also can produce according to customers' requests

7,Coil diameter: ID 420/ 508mm, OD from 1,000 to 1,250mm

8,Package: Anti-rust paper,corner protected. by sheet or coils according customer's require.

9, Applications: metal package usage like paint, chemical can,aerosol can and different food can production,

Also battery,electric cable and other industries

| Tinplate specifications | |||

| Steel Type | SPCC, MR | ||

| Temper(BA&CA) | T1~T5 | ||

| Coating | 1.1~11.2g/m2 | ||

| Thickness and tolerance | 0.15~0.50mm(Tolerance: _+0.01 mm) | ||

| Width & tolerance | 300~1000mm (Tolerance: 0~3mm) | ||

| Cut length & tolerance | 450~``50mm (Tolerance: 0~3mm ) | ||

| Coil inside diameter | 420/508mm | ||

| Coil Weight | 3~10 MT | ||

| Passivation | 311 | ||

| Oiling | DOS | ||

| Surface Finish | Bright, Stone, Silver, Matte | ||

| Packaging | Seaworthy Standard with wooden pallet | ||

| Standards Available | GB/T2520, JIS G3303, ASTM A623M & EN10202 | ||

| Special specitications are available on request. | |||

| Tin coating weight | |||

| Type | Designation of tin coating weight | Min.average tin coating weight(g/m2) | Former Coating Designation |

| Equal tin coating | 1.4/1.4 | 1.2/1.2 | #15 |

| 2.2/2.2 | 2.0/2.0 | #20 | |

| 2.8/2.8 | 2.45/2.45 | #25 | |

| 5.6/5.6 | 5.05/5.05 | #50 | |

| 8.4/8.4 | 7.55/7.55 | #75 | |

| 11.2/11.2 | 10.1/10.1 | #100 | |

| Differentially Coating | 1.4/2.8 | 1.2/2.45 | #15/25 |

| 2.2/2.8 | 2.2/2.45 | #20/25 | |

| 2.8/5.6 | 2.45/5.05 | #25/50 | |

| 2.8/8.4 | 2.45/7.55 | #25/75 | |

| 2.8/11.2 | 2.45/10.1 | #25/100 | |

| 5.6/8.4 | 5.05/7.55 | #50/75 | |

| 5.6/11.2 | 5.05/10.1 | #50/100 | |

| 8.4/11.2 | 7.55/10.1 | #75/100 | |

| Surface finish | |||

| Surface finish | Nominal surface roughness (um Ra) | Characteristic | |

| Bright finish | ≤Q0.35 | Glazed surface obtained after melting treatment of electrotinned smooth raw materail strip with extremely fine rubstone fingure by processing. | |

| Stone finish | 0.25~0.60 | Glazed surface obtained after melting treatment of electrotinned smooth raw materail stripfeaturing certain rubstone figures. | |

| Silver finish | 0.50~1.00 | Glazed surface obtained after melting treatment of electrotinned smooth raw material strip with rough matt furface. | |

| Matte finish | 0.80~2.50 | Matt surface of general matt raw material strip without melting treatment. | |

- Q: What are the advantages of using tinplate for jewelry?

- There are several advantages of using tinplate for jewelry. Firstly, tinplate is highly durable and resistant to corrosion, making it ideal for long-lasting jewelry pieces. Secondly, tinplate is lightweight, making it comfortable to wear for extended periods. Additionally, tinplate is easy to mold and shape into various intricate designs, allowing for unique and creative jewelry pieces. Lastly, tinplate is an affordable material, making it a cost-effective option for both manufacturers and consumers.

- Q: Can tinplate packaging be used for personal care products?

- Yes, tinplate packaging can be used for personal care products. Tinplate is a durable and lightweight material that provides good protection against moisture, light, and air. It is commonly used for packaging cosmetics, skincare products, and other personal care items. Additionally, tinplate packaging offers a premium and aesthetic appeal, making it suitable for various personal care product ranges.

- Q: What are the common printing techniques for tinplate?

- The common printing techniques for tinplate include lithography, offset printing, and silk-screen printing.

- Q: Can tinplate be used for electrical enclosures?

- Yes, tinplate can be used for electrical enclosures. Tinplate is a type of steel coated with a thin layer of tin, which provides excellent protection against corrosion. This makes it a suitable material for electrical enclosures as it ensures durability and helps maintain the integrity of the enclosed electrical components. Additionally, tinplate is relatively lightweight and cost-effective, making it a popular choice for various industrial applications, including electrical enclosures.

- Q: Can tinplate be used for high-speed packaging lines?

- Yes, tinplate can be used for high-speed packaging lines. Tinplate, which is a thin steel sheet coated with a layer of tin, offers excellent strength and durability, making it suitable for fast-paced packaging operations. Its smooth surface allows for easy printing and labeling, while its corrosion resistance ensures the longevity of packaged goods. Additionally, tinplate's ability to withstand high temperatures and its recyclability make it a popular choice for high-speed packaging lines in various industries such as food and beverage.

- Q: What are the advantages of using tinplate for gift packaging?

- One of the advantages of using tinplate for gift packaging is its durability. Tinplate is a strong and sturdy material that can withstand rough handling and protect the contents of the gift. Additionally, tinplate is resistant to corrosion and can keep the gift in good condition for a longer period of time. Another advantage is its aesthetic appeal. Tinplate can be easily decorated and customized, allowing for unique and eye-catching gift packaging designs. It also gives a premium and luxurious feel to the gift, enhancing its overall presentation. Lastly, tinplate is eco-friendly as it is recyclable, making it a sustainable choice for gift packaging.

- Q: How is tinplate stored and transported?

- Tinplate is typically stored and transported in rolls or sheets. It is commonly packaged in coils and secured with strapping or wrapping to prevent damage during transportation. These coils or sheets are then loaded onto trucks, ships, or trains for distribution to manufacturers and consumers. Additionally, proper handling and storage conditions are crucial to maintain the quality of tinplate, such as protecting it from moisture, extreme temperatures, and physical impact.

- Q: What is the purpose of tinplate coating?

- The purpose of tinplate coating is to provide a protective layer of tin on steel or iron surfaces to prevent corrosion and enhance the appearance of the material.

- Q: How does tinplate contribute to the sterility of medical equipment?

- Tinplate contributes to the sterility of medical equipment by providing a protective barrier that prevents the growth of bacteria and other microorganisms. The tin coating on the steel surface of the tinplate acts as a barrier against moisture and oxygen, preventing rusting and corrosion. This not only maintains the integrity of the equipment but also ensures that no contaminants are introduced into the medical environment. Additionally, tinplate is easy to clean and sterilize, further enhancing its contribution to the sterility of medical equipment.

- Q: Can tinplate packaging be used for stationery products?

- Yes, tinplate packaging can be used for stationery products. Tinplate packaging is durable, lightweight, and offers protection against moisture, making it an ideal choice for storing and packaging various stationery items such as pens, pencils, erasers, and other small office supplies. Additionally, tinplate packaging can be customized with attractive designs and branding, making it visually appealing for consumers.

Send your message to us

Tinplate with Prime Quality and Competitive Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords