Electrolytic Tinplate of High Quality for Metal Container 0.185mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Electrolytic Tinplate of High Quality for Metal Container 0.185mm Description

Electrolytic Tinplate is a thin steel sheet coated by tin. It has an extremely beautiful metallic luster as well as excellent properties in corrosion resistance, solder ability, and weld ability.

2.Main Features of the Electrolytic Tinplate of High Quality for Metal Container 0.185mm

Electrolytic Tinplate undoubtedly enjoys the pride of place as a packaging medium especially for food. It owes its unique position to its "nine layer sandwich structure", each of which contributes to its eminence as a packing material. The steel base of electrolytic tinplate provides the necessary strength and formability for can fabrication. The tin-iron alloy layer provides the bond between the steel and free tin layer. The free tin layer is not only responsible for the attractive bright finish and ease of solderability but is also non-toxic- a factor of vital importance in food packaging!

Tinplate is also widely used for making all types of containers such as food cans, beverage cans, and artistic cans, tea cans, painting cans, chemical package cans and dry food package cans, metal printing etc. Its applications are not limited to containers; recently, electrolytic tinplate has also been used for making electrical machinery parts and many other products.

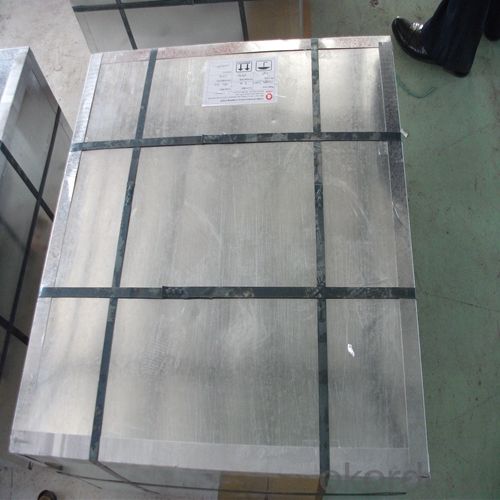

3.Electrolytic Tinplate of High Quality for Metal Container 0.185mm Images

4.Electrolytic Tinplate of High Quality for Metal Container 0.185mm Specification

Standard:BS EN 10202

Material: SPCC

Thickness:0.185mm

Width:700mm

Temper: T4

Annealing: CA

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil

Passivation:311

Oil: DOS

Surface: silver

5.FAQ of Electrolytic Tinplate of High Quality for Metal Container 0.185mm

1. What is the delivery time for your prime quality tinplate?

Usually 35 days after order confirmation.

2. What is your Minimum Order Quantity?

Usually MOQ is 50tons for one single size, for trial order, it can be 25 tons.

3. What is the payment term?

The most common we use is L/C at sight or TT. We can also try use other terms.

- Q: What are the main factors affecting tinplate coil surface finish?

- The main factors affecting tinplate coil surface finish include the quality of the tin coating, the cleanliness of the substrate, the condition of the rolling mill, the temperature and pressure during the rolling process, the presence of impurities or contaminants, and the effectiveness of post-processing treatments such as annealing or tempering.

- Q: What are some common tinplate products?

- Some common tinplate products include food cans, beverage cans, aerosol cans, metal closures, and tinplate packaging for various consumer goods.

- Q: What are the main differences between tinplate and tinplate laminates in terms of design flexibility?

- Tinplate offers limited design flexibility due to its rigid nature, while tinplate laminates provide greater design flexibility as they can be combined with other materials, allowing for more creative and versatile packaging options.

- Q: How is tinplate coated with anti-tarnish materials?

- Tinplate is coated with anti-tarnish materials through a process called passivation. This involves applying a thin layer of protective coating onto the tinplate surface to prevent oxidation and tarnishing. The coating can be made from various materials such as organic compounds or inorganic substances like chrome or zinc, which create a barrier against moisture and other corrosive elements. This helps to maintain the aesthetic appeal and durability of the tinplate over time.

- Q: How does tinplate perform in terms of odor resistance?

- Tinplate generally demonstrates good odor resistance due to its non-reactive nature and protective tin coating, which helps prevent any unwanted odors from permeating the material or affecting the contents stored inside.

- Q: What are the different ways to label tinplate closures?

- There are several ways to label tinplate closures, including direct printing, labeling with adhesive labels, embossing, and laser engraving. Each method offers its own advantages and can be chosen based on factors such as cost, durability, and desired aesthetic appeal.

- Q: What are the main applications of tinplate in the energy industry?

- Tinplate is commonly used in the energy industry for various applications such as the production of battery casings, electrical components, and packaging for energy storage devices. Its corrosion resistance, strength, and ability to withstand extreme temperatures make it a preferred material for these purposes. Additionally, tinplate's non-reactive nature ensures the integrity of energy storage systems, making it an ideal choice for the energy industry.

- Q: How does tinplate compare to other packaging materials?

- Tinplate is highly versatile and durable, making it an excellent choice for packaging materials. It offers superior protection against moisture, oxygen, and light, ensuring the freshness and quality of the packaged products. Additionally, tinplate is eco-friendly as it is 100% recyclable, making it a sustainable choice. Its strength and resistance to corrosion further enhance its appeal compared to other packaging materials.

- Q: Can tinplate be used for energy storage applications?

- No, tinplate cannot be used for energy storage applications as it is primarily used in the packaging industry due to its lightweight and protective properties for food and beverage containers. Energy storage requires specialized materials such as lithium-ion batteries or supercapacitors.

- Q: Does the tinplate have a tensile rate? Thank you heroes!

- Elongation or section shrinkage is the main index of plasticity of metal materials. The quality of plasticity depends on many factors, and the material is only one of them. For example, temperature and stress state will also affect the plasticity. Marble in high-pressure liquid can also be a good extension of humor.

Send your message to us

Electrolytic Tinplate of High Quality for Metal Container 0.185mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords