Tinplate with prime quality hot sale products

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 20000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

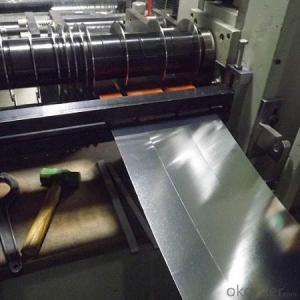

Tinplate with prime quality hot sale products

Product Description

- Tinplate, as the name suggests, is coated on both sides with pure tin at various coating weights between 1 and 12 grams per square meter. It has an extremely beautiful metallic luster as well as excellent properties in corrosion resistance, solder ability, and weld ability.

2. Main Features

Tinplate is widely used for making all type of containers, electrical machinery parts and many other products.

3 Pictures.

4. Applications

- Chemical and Painting Cans

- Dry food cans, such as fancy cans, biscuit cans, milk powder cans, tea cans

- Liquid food cans, such as edible oil cans, beverage cans, tomato paste cans

- Sea food cans

- Crown corks, easy open ends

- Electrical Machinery parts

- Bakeware and household kitchen parts

5.FAQ

CNBM is a state- owned enterprise, top 1 in China steel industry, top 500 world wide. Our tinplate annual capacity is 400,000metric tons. First class level with competitive price.

- Q: What is the shelf life of tinplate canned goods?

- The shelf life of tinplate canned goods can vary depending on the specific product and storage conditions. Generally, these canned goods have a shelf life of 2 to 5 years when stored in a cool, dry, and dark place. However, it is recommended to check the expiration date on the can and discard any cans that are bulging, leaking, or have a foul odor as they may be spoiled.

- Q: What are the common uses of tinplate?

- Tinplate is commonly used in the packaging industry for making cans, containers, and lids for food and beverages. It is also used in the production of aerosol cans, paint cans, and metal closures. Additionally, tinplate is used for making various household items such as kitchen utensils, storage boxes, and tin toys.

- Q: How to distinguish galvanized plate and tin plate

- From the outside, hot galvanized, electro galvanized tin plate surface is rough, thick tin layer of light and bright, thin tin layer, hot galvanized galvanized is not only the contest, Matt

- Q: What are the common decorative options for tinplate packaging?

- Common decorative options for tinplate packaging include printing, embossing, debossing, hot stamping, and lithography. These techniques can be used to create intricate designs, patterns, logos, and text on the surface of the tinplate packaging, making it visually appealing and attractive to consumers.

- Q: Can tinplate be used for packaging baby food and formula?

- Yes, tinplate can be used for packaging baby food and formula. Tinplate is a commonly used material for food packaging due to its durability, corrosion resistance, and ability to protect against light and oxygen. It is also considered safe for food contact and can be easily sterilized, making it suitable for packaging sensitive products like baby food and formula.

- Q: How is tinplate affected by different types of beverages?

- Tinplate is generally resistant to most types of beverages, including acidic ones. However, certain highly acidic or corrosive beverages, such as fruit juices, can cause a chemical reaction with the tin coating, potentially leading to a metallic taste or discoloration. To prevent this, tinplate cans are often lined with a protective coating, such as lacquer or polymer, to ensure the beverage's quality and safety.

- Q: How does tinplate ensure the freshness of pet food?

- Tinplate ensures the freshness of pet food by providing an airtight and durable packaging solution. This material is highly resistant to corrosion and helps to prevent external factors such as moisture, light, and oxygen from entering the packaging and spoiling the food. Additionally, tinplate offers a long shelf life for pet food, preserving its nutritional value and flavor until it is consumed by pets.

- Q: What are the main challenges in tinplate recycling?

- One of the main challenges in tinplate recycling is the separation of tin coating from the steel substrate, as the two materials have different melting points. Additionally, the presence of other contaminants such as lacquers and coatings on the tinplate can complicate the recycling process. Furthermore, the collection and sorting of tinplate waste can be challenging due to its prevalence in various product packaging, making it difficult to streamline the recycling system. Overall, technological advancements and increased awareness are necessary to overcome these challenges and improve the efficiency of tinplate recycling.

- Q: How is tinplate used in the packaging industry?

- Tinplate is commonly used in the packaging industry as it provides a protective and durable coating for various products. It is often used to create cans and containers for food, beverages, and other consumer goods. Tinplate ensures the preservation of the contents, prevents contamination, and extends shelf life. Additionally, its versatility allows for easy printing and labeling, making it an ideal choice for branding and marketing purposes.

- Q: What are the main applications of tinplate in the pet food industry?

- The main applications of tinplate in the pet food industry include packaging for wet and dry pet food products, as it provides a durable and protective barrier against moisture, air, and light. Tinplate cans also offer convenience in terms of storage and transportation, ensuring the freshness and quality of pet food while being easy to handle for pet owners.

Send your message to us

Tinplate with prime quality hot sale products

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 20000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords