Tinplate with Prime Quality for Tin Box Making

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Tinplate Specification

Tinplate, as the name suggests, is coated on both sides with pure tin at various coating weights between 1 and 12 grams per square meter. It has extremely beautiful metalllic luster as well as excellent properties in corrosion resistance, solder ability, and weld ability.

Tinplate Applications

Tinplate is widely used for making all types of containers, electrical machinery parts and many other products.

Chemicals and painting cans

Dry food cans, such as fancy cans, biscuit cans, milk powder cans, tea cans.

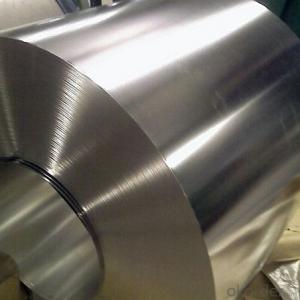

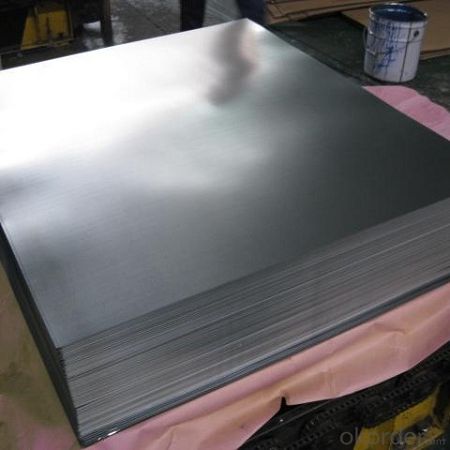

Tinplate Pictures

Tinplate Features

Steel Type: MR, SPCC

Temper(BA& CA): T1- T5, DR8- DR10

Coating: 1.1- 8.4g/m^2

Tickness: 0.15- 0.,50mm

Width: 600-1010mm

I.D: 508mm

Coil weight: 3- 10mt

Passivation: 311

Oiling: DOS

Surface finish: Bright, Stone

Quantity for 20 Feet FCL: 20- 25MT

Package: Seaworthy Export Standard Wooden Pallet

Application

Tinplate is widely used for making all types of containers, electrical machinery parts and many other products

Chemicals and painting cans

Dry food ccans, such as fancy cans, biscuit cans, milk powder cans, tea cans.

Liquid food cans, such as edible oil cans, beverage cans, Tomato paste cans

Sea food cans

Crown corks, easy open ends

Electrical machinery parts

Bakeware and household kitchen parts

Production Standard

GB/T 2520-2000

JIS G3303-2002

DIN EN 10202-2001

ASTM A623M-2002

ISO 11949-1995

- Q: What are the advantages of using tinplate in packaging?

- There are several advantages of using tinplate in packaging. Firstly, tinplate has excellent corrosion resistance, ensuring that the packaged product remains protected and fresh for a longer period of time. Secondly, tinplate is highly durable and can withstand rough handling during transportation and storage. Additionally, tinplate is easily customizable and can be printed with attractive designs, enhancing the visual appeal of the packaging. Furthermore, tinplate is a sustainable packaging option as it is 100% recyclable, contributing to environmental preservation. Overall, the use of tinplate in packaging offers enhanced product protection, durability, customization options, and sustainability benefits.

- Q: What are the common sealing options for tinplate containers?

- The common sealing options for tinplate containers include twist-off caps, easy-open ends, peelable lids, and screw-on lids.

- Q: What are the common misconceptions about tinplate packaging?

- One common misconception about tinplate packaging is that it is not environmentally friendly. While it is true that tinplate packaging requires energy and resources to produce, it is actually one of the most recycled packaging materials available. Another misconception is that tinplate packaging is easily dented or damaged. In reality, tinplate is known for its durability and ability to protect the contents inside. Additionally, some people believe that tinplate packaging is outdated or old-fashioned, when in fact it is often used for its aesthetic appeal and can be customized in various modern and innovative ways.

- Q: What are the common sizes of tinplate sheets?

- The common sizes of tinplate sheets typically range from 0.15mm to 0.5mm in thickness, and can vary in width from 600mm to 1200mm.

- Q: What are the main components of tinplate?

- The main components of tinplate are steel and tin.

- Q: What are the main challenges in tinplate inventory management?

- The main challenges in tinplate inventory management include managing fluctuating demand, ensuring accurate forecasting, optimizing storage space, minimizing waste and obsolescence, and maintaining efficient logistics and supply chain operations.

- Q: How does tinplate perform in terms of odor and taste retention?

- Tinplate is known for its excellent odor and taste retention properties. It forms a protective barrier that prevents any transfer of odors and flavors between the packaging material and the contents. This makes tinplate a preferred choice for packaging sensitive food and beverage products, ensuring that their quality and taste remain intact.

- Q: How does tinplate perform in terms of light blocking?

- Tinplate is an effective material for light blocking. Its thick and durable structure prevents light from passing through, making it suitable for applications that require complete light protection, such as packaging for light-sensitive products or containers for storing food and beverages.

- Q: What are the limitations of using tinplate?

- There are several limitations to using tinplate. Firstly, it is relatively expensive compared to other packaging materials such as aluminum or plastic. Secondly, tinplate is not as lightweight as some alternative materials, which can add to transportation costs and increase carbon footprint. Additionally, tinplate is susceptible to corrosion and can rust if not properly coated or maintained. Lastly, its use is limited to certain applications, and it may not be suitable for products that require high heat or pressure resistance.

- Q: What are the main quality standards for tinplate?

- The main quality standards for tinplate include thickness, coating weight, surface finish, and adhesion. These standards ensure that tinplate meets the required strength, corrosion resistance, and aesthetic properties necessary for its various applications such as food packaging and industrial uses.

Send your message to us

Tinplate with Prime Quality for Tin Box Making

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords