Tinplate with First- Class Level for Tin Cans Making

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Tinplate with First- Class Level for Tin Cans Making

Tinplate Specification

Tinplate, as the name suggests, is coated on both sides with pure tin at various coating weights between 1 and 12 grams per square meter. It has extremely beautiful metalllic luster as well as excellent properties in corrosion resistance, solder ability, and weld ability.

Tinplate Applications

Tinplate is widely used for making all types of containers, electrical machinery parts and many other products.

Chemicals and painting cans

Dry food cans, such as fancy cans, biscuit cans, milk powder cans, tea cans.

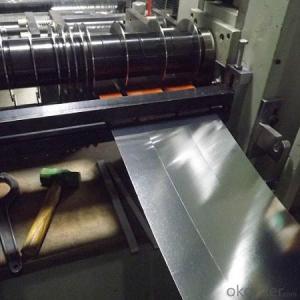

Tinplate Pictures

Tinplate Features

Steel Type: MR, SPCC

Temper(BA& CA): T1- T5, DR8- DR10

Coating: 1.1- 8.4g/m^2

Tickness: 0.15- 0.,50mm

Width: 600-1010mm

I.D: 508mm

Coil weight: 3- 10mt

Passivation: 311

Oiling: DOS

Surface finish: Bright, Stone

Quantity for 20 Feet FCL: 20- 25MT

Package: Seaworthy Export Standard Wooden Pallet

Application

Tinplate is widely used for making all types of containers, electrical machinery parts and many other products

Chemicals and painting cans

Dry food ccans, such as fancy cans, biscuit cans, milk powder cans, tea cans.

Liquid food cans, such as edible oil cans, beverage cans, Tomato paste cans

Sea food cans

Crown corks, easy open ends

Electrical machinery parts

Bakeware and household kitchen parts

Production Standard

GB/T 2520-2000

JIS G3303-2002

DIN EN 10202-2001

ASTM A623M-2002

ISO 11949-1995

- Q: What are the different printing techniques used on tinplate?

- There are several different printing techniques used on tinplate, including lithography, offset printing, screen printing, and digital printing. These methods allow for high-quality and vibrant designs to be applied to tinplate surfaces, making them suitable for various packaging and promotional materials.

- Q: What are the factors that determine the lifespan of tinplate packaging?

- The factors that determine the lifespan of tinplate packaging include the quality of the tin coating, the thickness of the tinplate material, the presence of protective coatings, the storage conditions (e.g., temperature and humidity), exposure to external elements (e.g., moisture, oxygen, and chemicals), and the overall handling and care during transportation and use.

- Q: Can tinplate be used for packaging petrochemical products?

- Yes, tinplate can be used for packaging petrochemical products. Tinplate is a type of steel coated with a thin layer of tin, providing it with excellent corrosion resistance and durability. These properties make it suitable for packaging various products, including petrochemicals, as it can protect the contents from external factors such as moisture and oxygen. Additionally, tinplate cans can be sealed tightly, ensuring the safety and integrity of the petrochemical products during storage and transportation.

- Q: What are the main applications of tinplate in the stationery industry?

- Tinplate is commonly used in the stationery industry for various purposes such as making pencil boxes, pen holders, and storage containers. Its durability, lightweight nature, and ability to be molded into different shapes make it ideal for creating functional and aesthetically pleasing stationery products. Additionally, tinplate's ability to resist moisture and protect its contents from damage makes it a preferred choice for items like pencil sharpeners and paper clips.

- Q: How does tinplate handle exposure to chemicals and solvents?

- Tinplate is known for its excellent resistance to chemicals and solvents. It forms a protective barrier that prevents the interaction between the metal and the substances it comes in contact with. This makes tinplate a reliable packaging material for various products, ensuring their quality and safety.

- Q: How does tinplate contribute to the overall durability of packaging?

- Tinplate contributes to the overall durability of packaging by providing a strong and protective barrier against external factors such as moisture, oxygen, and light. Its corrosion-resistant properties ensure that the contents of the packaging remain fresh and intact for a longer period of time. Additionally, tinplate's strength allows for stacking and transportation without damage, ensuring the longevity of the packaging and extending the shelf life of the products inside.

- Q: Can tinplate be used for outdoor signage?

- Yes, tinplate can be used for outdoor signage. Tinplate is a durable material that can withstand various weather conditions, making it suitable for outdoor applications such as signage. Its corrosion-resistant properties and ability to be easily shaped and printed on make it a popular choice for outdoor signage.

- Q: Is it necessary for the two cold rolling in the process of tinplate production, such as tempering and cold rolling (also called flatness)?

- The leveling process is only to change the yield platform or to improve the plate shape. Under normal pressure is very small, can not be considered cold rolled in the true sense.

- Q: Can tinplate be used for ammunition?

- Yes, tinplate can be used for ammunition. It is commonly used for shotgun shells and some types of small caliber ammunition. Tinplate provides durability and corrosion resistance, making it suitable for preserving the integrity of ammunition during storage and transportation.

- Q: What are the main challenges in tinplate supply chain management?

- The main challenges in tinplate supply chain management include ensuring a steady and reliable supply of tinplate, managing fluctuations in demand and supply, coordinating multiple stakeholders in the supply chain, optimizing transportation and logistics, ensuring product quality and compliance with regulations, and mitigating risks such as price volatility and disruptions in the supply chain.

Send your message to us

Tinplate with First- Class Level for Tin Cans Making

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords