Electrolytic Tinplate Coils of High Quality for Metal Container 0.19mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Electrolytic Tinplate Coils of High Quality for Metal Container 0.19mm Description

Electrolytic Tinplate is a thin steel sheet coated by tin. It has an extremely beautiful metallic luster as well as excellent properties in corrosion resistance, solder ability, and weld ability.

2.Main Features of the Electrolytic Tinplate Coils of High Quality for Metal Container 0.19mm

Tinplate is widely used for making all types of containers such as food cans, beverage cans, and artistic cans, tea cans, painting cans, chemical package cans and dry food package cans, metal printing etc. Its applications are not limited to containers; recently, tinplate has also been used for making electrical machinery parts and many other products.

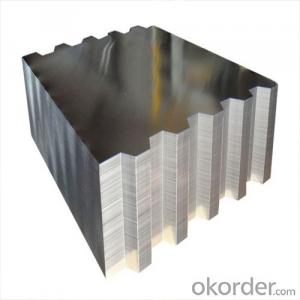

3.Electrolytic Tinplate Coils of High Quality for Metal Container 0.19mm Images

4.Electrolytic Tinplate Coils of High Quality for Metal Container 0.19mm Specification

Standard:BS EN 10202

Material: SPCC

Thickness:0.19mm

Width:736mm

Temper: T2

Annealing: BA

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil

Passivation:311

Oil: DOS

Surface: silver

5.FAQ of Electrolytic Tinplate Coils of High Quality for Metal Container 0.19mm

- What is your producation capacity per month?

We can produce about 25,000tons

- What is tinning and how does it work?

Tinning is the process of thinly coating sheets of wrought iron or steel with tin, and the resulting product is known as tinplate. It is most often used to prevent rust.

- Do you only have prime quality tinplate?

We can supply both prime and second quality tinplate.

- Q: Can tinplate be used for promotional or gift packaging?

- Yes, tinplate can be used for promotional or gift packaging. It is a versatile material that offers durability, aesthetic appeal, and the ability to be customized with various designs and finishes. Tinplate packaging can enhance the perceived value of a product or gift, making it an excellent choice for promotional purposes.

- Q: What are the common storage and handling requirements for tinplate?

- The common storage and handling requirements for tinplate include keeping it in a clean and dry environment to prevent rusting or corrosion. It should be stored in a well-ventilated area away from direct sunlight and sources of heat. Tinplate should be handled with care to avoid any sharp impacts or bending, as it can affect its structural integrity. It is also important to stack tinplate properly, ensuring that there is no excessive weight on top of it to prevent deformation. Regular inspection and maintenance are necessary to detect any signs of damage or corrosion early on.

- Q: What are the typical finishing options for tinplate products?

- The typical finishing options for tinplate products include tin plating, lacquering, lithography, embossing, and varnish coating.

- Q: Can tinplate packaging be used for household products?

- Yes, tinplate packaging can be used for household products. It is a versatile and durable material that offers protection and preservation to various household items, such as food, beverages, cosmetics, and cleaning products. Tinplate packaging is also recyclable and eco-friendly, making it a suitable choice for sustainable packaging solutions.

- Q: Can tinplate be used for toys and games?

- Yes, tinplate can definitely be used for toys and games. Tinplate is a durable and versatile material that can be easily molded into various shapes and sizes, making it suitable for manufacturing different types of toys and games. Its corrosion-resistant properties also ensure the longevity of the toys, making it a popular choice in the industry.

- Q: Can tinplate be used for packaging of organic products?

- Yes, tinplate can be used for packaging of organic products. Tinplate is a type of steel coated with a thin layer of tin, providing excellent protection against corrosion and ensuring food safety. It is widely used in the packaging industry, including for organic products, as it is considered a safe and sustainable packaging material.

- Q: Can tinplate be used for packaging of flammable liquids?

- No, tinplate is not suitable for packaging flammable liquids as it is not resistant to corrosion and may react with the liquid, potentially causing leaks or fire hazards.

- Q: Can tinplate be used for bulk packaging?

- Yes, tinplate can be used for bulk packaging. Tinplate is a commonly used material for packaging due to its durability, strength, and resistance to corrosion. It is often used in the food and beverage industry to package products in large quantities efficiently and securely.

- Q: Can tinplate be used for microwave-safe packaging?

- No, tinplate cannot be used for microwave-safe packaging as it is not suitable for microwave heating.

- Q: How does tinplate compare to other packaging materials?

- Tinplate offers several advantages compared to other packaging materials. It is highly durable, providing excellent protection for the packaged goods. Tinplate is also resistant to corrosion, ensuring the longevity of the packaging. It is lightweight, making it cost-effective for transportation and storage. Additionally, tinplate is versatile, allowing for various shapes and sizes of packaging, and it provides an attractive appearance, enhancing the visual appeal of the product. Overall, tinplate is a reliable and efficient packaging material that offers numerous benefits in comparison to other alternatives.

Send your message to us

Electrolytic Tinplate Coils of High Quality for Metal Container 0.19mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords