Electrolytic Tinplate Sheets or Coils for Industrial Package 0.195mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Electrolytic Tinplate Sheets or Coils for Industrial Package 0.195mm Description

The origin of tinplate is from Bohemian, from 14th century, the people there began to produce tinplate. Also known as electrolytic tinplate, which stand for tin coating on the surface of cold rolled coil for preventing rust. The unique characteristics of tinplate steel decides its comprehensive range of application in international tinplate packaging industry. With the abundance extend of CC and DR steel material, and tin free steel, which enhance the development of technology of packaging industrialization, the innovation is ubiquitous in tinplate steel.

2.Main Features of the Electrolytic Tinplate Sheets or Coils for Industrial Package 0.195mm

The feature of anti-oxidation, various kinds and beauty in printing enable tinplate enjoys widely usage in food can package, pharmaceutical package, daily application packing, apparatus package and industrial pack.

From the first food can to be produced in the year of 1810 in British, the development trend of tinplate has become thinner thickness and less tin coating to adjust the change of can industry and save cost.

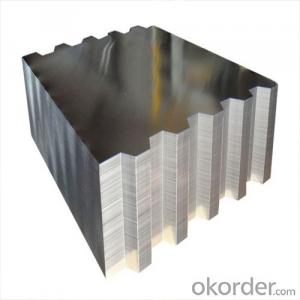

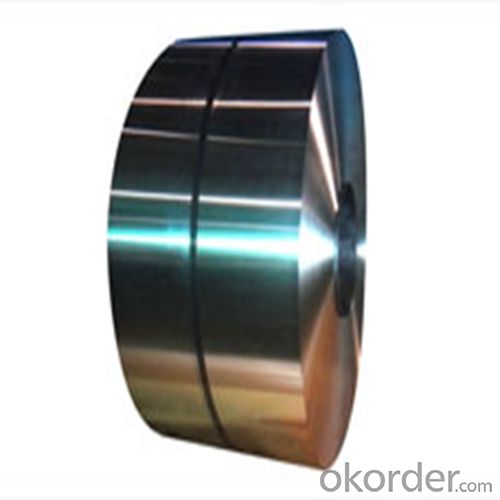

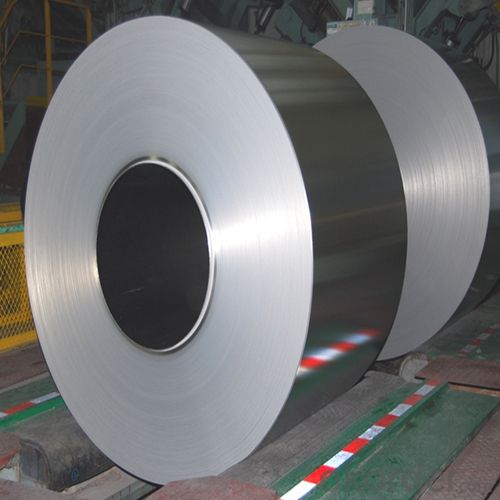

3.Electrolytic Tinplate Sheets or Coils for Industrial Package 0.195mm Images

4.Electrolytic Tinplate Sheets or Coils for Industrial Package 0.195mm Specification

Standard: GB/T2520-2000

Material: MR

Thickness:0.195mm

Width: 615mm

Temper: T4

Annealing: CA

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil 1~1.7 tons/sheets bundle

Passivation:311

Oil: DOS

Surface Finish: bright

5.FAQ of Electrolytic Tinplate Sheets or Coils for Industrial Package 0.195mm

- What is the delivery time for your prime quality tinplate?

Usually 45 days after order confirmation for MR steel, and 35 days for SPCC.

- Do you also offer secondary quality stock tinplate?

Yes, we also offer secondary quality stock tinplate especially for industrial use.

- Can you offer some details about your package?

For sheets: plastic or waterproof paper, metallic cover and angles, steel strips,wooden pallet.

For Coils: plastic or waterproof paper,plastic protect plate,steel strips.

- Which port do you ship from?

We can ship from any China main port, but mostly Shanghai.

- What is the payment term?

The most common we use is L/C at sight or TT. We can also try use other terms.

- Q: What are the regulations regarding tinplate packaging?

- The regulations regarding tinplate packaging vary depending on the country or region. However, in general, tinplate packaging must comply with certain standards to ensure its safety and suitability for use. These standards may include specifications for the tinplate material, its thickness, coating composition, and overall quality. Additionally, regulations often exist concerning labeling requirements, such as providing accurate information about the contents, proper handling instructions, and any necessary warnings. It is essential for manufacturers and suppliers to stay updated on the specific regulations applicable to their respective markets to ensure compliance and consumer safety.

- Q: How does tinplate perform in terms of resistance to chemical agents?

- Tinplate demonstrates good resistance to chemical agents due to its protective tin coating, which acts as a barrier against corrosion and interaction with various substances.

- Q: Can tinplate be used for frozen food packaging?

- Yes, tinplate can be used for frozen food packaging. Tinplate is a type of steel coated with a thin layer of tin, which provides excellent durability and corrosion resistance. These properties make it suitable for packaging frozen foods as it can effectively protect the food from moisture and oxygen, ensuring its quality and extending its shelf life. Additionally, tinplate is also recyclable, making it an environmentally friendly choice for frozen food packaging.

- Q: How does tinplate contribute to the functionality of household goods?

- Tinplate contributes to the functionality of household goods by providing a durable and corrosion-resistant coating that protects the underlying material from moisture, oxygen, and other environmental factors. This ensures that household items such as cans, containers, and appliances have a longer lifespan and remain in good condition. Additionally, tinplate's versatility allows for easy shaping and forming, enabling the creation of various functional and aesthetically pleasing designs for household goods.

- Q: Can tinplate be used for renewable energy applications?

- Yes, tinplate can be used for renewable energy applications. It is commonly used for manufacturing solar panels and wind turbines due to its high durability, corrosion resistance, and electrical conductivity properties. Tinplate is also recyclable, making it an environmentally friendly choice for renewable energy projects.

- Q: What are the hygiene benefits of tinplate packaging?

- Tinplate packaging offers several hygiene benefits, including its ability to effectively protect food and beverages from contamination. The non-reactive nature of tinplate helps maintain the quality and freshness of the products, ensuring their safety for consumption. Additionally, tinplate packaging is impermeable to light and oxygen, preventing the growth of bacteria, mold, and other microorganisms that can cause spoilage. The durability and resistance of tinplate also contribute to its hygiene advantages, as it can withstand handling and transportation without compromising the integrity of the contents.

- Q: How does tinplate compare to other packaging materials in terms of brand recognition?

- Tinplate stands out among other packaging materials in terms of brand recognition due to its unique and timeless appeal. Its classic metallic appearance and durability evoke a sense of quality and nostalgia, making it highly recognizable and associated with premium brands. Additionally, tinplate allows for intricate and vibrant designs, ensuring that brands can effectively showcase their logos and visuals, further enhancing brand recognition.

- Q: What are the different types of tinplate seams?

- There are three main types of tinplate seams: lap seam, double seam, and open seam.

- Q: How does tinplate contribute to the convenience of pet care products?

- Tinplate contributes to the convenience of pet care products by providing a durable and lightweight packaging option that helps preserve the quality and freshness of the products. It is also easily recyclable, ensuring sustainability while offering a convenient solution for pet owners.

- Q: How does tinplate perform in terms of temperature resistance?

- Tinplate performs well in terms of temperature resistance, as it can withstand high temperatures without warping or losing its structural integrity.

Send your message to us

Electrolytic Tinplate Sheets or Coils for Industrial Package 0.195mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords