Electrolytic Tinplate Sheets or Coils for Industrial Package 0.25mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Electrolytic Tinplate Sheets or Coils for Industrial Package 0.25mm Description

Electrolytic tinplate, which stand for tin coating on the surface of cold rolled coil for preventing rust. The unique characteristics of tinplate steel decides its comprehensive range of application in international tinplate packaging industry. With the abundance extend of CC and DR steel material, and tin free steel, which enhance the development of technology of packaging industrialization, the innovation is ubiquitous in tinplate steel.

2.Main Features of the Electrolytic Tinplate Sheets or Coils for Industrial Package 0.25mm

The feature of anti-oxidation, various kinds and beauty in printing enable tinplate enjoys widely usage in food can package, pharmaceutical package, daily application packing, apparatus package and industrial pack.

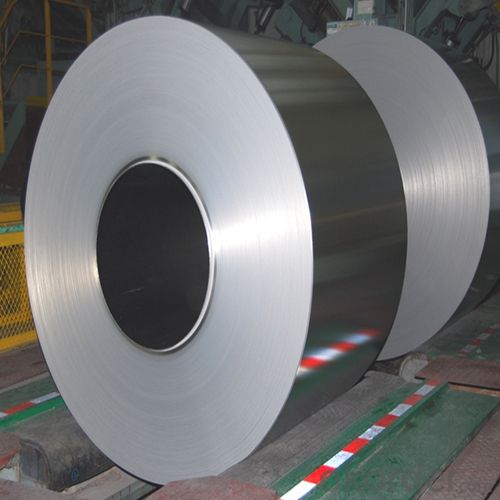

3.Electrolytic Tinplate Sheets or Coils for Industrial Package 0.25mm Images

4.Electrolytic Tinplate Sheets or Coils for Industrial Package 0.25mm Specification

Standard: GB/T2520-2000

Material: MR

Thickness:0.25mm

Width: 615mm

Temper: T3

Annealing: BA

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil 1~1.7 tons/sheets bundle

Passivation:311

Oil: DOS

Surface Finish: bright

5.FAQ of Electrolytic Tinplate Sheets or Coils for Industrial Package 0.25mm

- What is the delivery time for your prime quality tinplate?

Usually 45 days after order confirmation for MR steel, and 35 days for SPCC.

- Do you also offer secondary quality stock tinplate?

Yes, we also offer secondary quality stock tinplate especially for industrial use.

- Can you offer some details about your package?

For sheets: plastic or waterproof paper, metallic cover and angles, steel strips,wooden pallet.

For Coils: plastic or waterproof paper,plastic protect plate,steel strips.

- Which port do you ship from?

We can ship from any China main port, but mostly Shanghai.

- What is the payment term?

The most common we use is L/C at sight or TT. We can also try use other terms.

- Q:Can tinplate packaging be used for sports equipment?

- Yes, tinplate packaging can be used for sports equipment. Tinplate is highly durable and can provide excellent protection for various types of sports equipment, such as balls, bats, or even smaller items like goggles or accessories. Additionally, tinplate packaging can be customized and designed in various shapes and sizes to fit the specific requirements of different sports equipment.

- Q:Is tinplate suitable for hot or cold food products?

- Tinplate is suitable for both hot and cold food products.

- Q:How can tinplate be customized for branding purposes?

- Tinplate can be customized for branding purposes through various methods such as printing, embossing, and labeling. The use of high-quality printing techniques allows for intricate designs, logos, and product information to be directly printed on the tinplate surface. Embossing techniques can add a three-dimensional effect to the branding, making it visually appealing and unique. Additionally, labels can be affixed to the tinplate, providing flexibility in changing branding elements or promoting different product lines. These customization options help businesses effectively market their brand and enhance their product's visibility on store shelves.

- Q:How does tinplate contribute to the overall durability of packaging?

- Tinplate contributes to the overall durability of packaging through its inherent strength, corrosion resistance, and ability to withstand extreme temperatures. It provides a protective barrier against moisture, oxygen, and light, which helps to preserve the quality and freshness of packaged goods. Additionally, tinplate's resistance to impact and puncture ensures that the packaging remains intact during handling, transportation, and storage, thereby extending the lifespan of the product.

- Q:What are the typical finishing options for tinplate products?

- The typical finishing options for tinplate products include painting, printing, coating, embossing, and varnishing. These options not only enhance the appearance of the tinplate products but also provide protection against corrosion and improve overall durability.

- Q:What are the typical manufacturing processes for tinplate products?

- The typical manufacturing processes for tinplate products include coil cutting, cleaning and coating, pressing or stamping, forming or shaping, welding or soldering, and final finishing or packaging.

- Q:What are the different sizes and shapes of tinplate packaging available?

- There are various sizes and shapes of tinplate packaging available, ranging from small tins for individual items such as lip balm or mints, to larger tins for products like cookies or tea. The shapes can also vary, including round, rectangular, or square tins, as well as specialty shapes like heart or star-shaped tins.

- Q:What are the advantages of using tinplate for household appliances?

- There are several advantages of using tinplate for household appliances. Firstly, tinplate is highly resistant to corrosion and rust, ensuring the longevity and durability of the appliances. Additionally, tinplate provides excellent heat resistance, making it suitable for appliances that generate high temperatures. Furthermore, tinplate is lightweight yet strong, allowing for easy handling and transportation of the appliances. Lastly, tinplate is a sustainable and eco-friendly material, as it is recyclable and reduces the carbon footprint of the manufacturing process.

- Q:How is tinplate manufactured?

- Tinplate is manufactured by coating thin sheets of steel with a layer of tin through a process known as electrolytic deposition. The steel sheets are first cleaned and then passed through an electrolyte bath containing a solution of tin salts. An electric current is applied, causing tin ions to be attracted to the steel surface, resulting in a uniform tin coating. Finally, the tin-coated steel is rolled and annealed to improve its mechanical properties, creating the final product known as tinplate.

- Q:Can tinplate be used for packaging agricultural products?

- Yes, tinplate can be used for packaging agricultural products. Tinplate is a type of steel coated with a thin layer of tin, which provides excellent protection against corrosion and preserves the quality of agricultural products. It is commonly used for packaging canned fruits, vegetables, and other perishable agricultural products. Additionally, tinplate is lightweight, recyclable, and offers a long shelf life, making it a suitable choice for packaging agricultural products.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Electrolytic Tinplate Sheets or Coils for Industrial Package 0.25mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords