Ductile Iron Pipes & Factory Prices C25 EN545/EN598/ISO2531 DN300

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Ductile Iron Pipe Description :

1) Pipes confirm to ISO2531,K9 class,T type joint,6m long,with inside cements lining conform to ISO4179, outside Zinc spraying(130g/m2) and bitumen coating(70μm) conform to ISO8179.

2) Pipe ends: Spigot and socket ends, with 100% SBR rubber gaskets accoding to ISO4633

3) we can do third party inspection according to customer's request.

4) Our products have been sold to many international market, such as Middle East and South East Asia and Africa.

2,Main Features of the Ductile Iron Pipe:

1).Quality guarantee

• Chemical checking

• NDE after rough machining

• Mechanical testing after heat treatment

• Final NDE,dimension inspected

2).Quality document

• Full Q.A document as per client request

3).Packing and Shipping

• standard export package(carton/wooden case/pallet)

• accept FOB,FAS,CNF,CIF door to door etc or customer designated shipping agent

4)Inspection

• In-house Foundry

• Third party inspection available upon requirement

5) Our goal

• To be your preferred partner

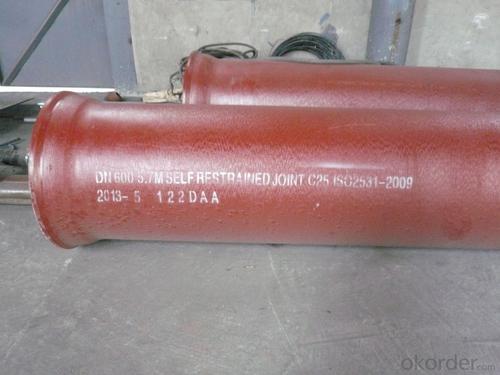

3,Ductile Iron Pipe Images:

4. Ductile Iron Pipe Specification:

Surface Finishes: Bare, Oiled, Mill Varnish, Galv,FBE, FBE Dual, 3LPE, 3LPP, Coal Tar,Concrete Coating and Tape Wrap

End Finishes: Beveled, Square Cut, Threaded, hat

Additional Services: Internal Coating

Packaging: packed in bag, plastic bag, steel strip, steel wire,double wire, iron box, wooden box, tarpaulin, plastic sheeting

Inspection: MOODY SGS BV GL DNV ABS LIOYD’S

Test: X-ray, UT, magnetic particle,inspection,hydrostatic test.

Processing service: Beveling, Threading, Slotting, Cut-to length, Bends, Quench and Temper, Fabrication, Double-jointing and On-site assistance

Documentary: MTC, material certification,Origin certification, CI or PI,Test Report, export licence, handling order, B/L,insurance policy,shipping instructions, contract, packing list etc.

5.FAQ:

We have organized several common questions for our clients,may help you sincerely:

1.Q: Why would you choose ductile iron pipe rather than other pipe materials?

A:The reasons are obvious for that not only ductile iron pipe possesses the inherent strength and flexibility of ductile

iron, combined with proven corrosion protection systems, but also the cost savings can be achieved from design to

installation and commissioning.

2.Q:Why can you guarantee the inner of pipes can’t be corroded?

A: High alumina cement mortar lining and sulphate-resistant cement mortar lining. These two special linings are applicable

to inner anti-corrosion for sewage pipes, improving resistance to erosion of the sewage components.

- Q: How does ductile iron pipe perform in areas with high traffic loads?

- Areas with high traffic loads greatly benefit from the exceptional performance of ductile iron pipe. Its superior strength and durability enable it to effectively handle heavy loads and withstand the impact caused by vehicular traffic. Ductile iron pipes possess a high resistance to bending and cracking, making them an ideal choice for applications in roadways, highways, and other areas with high traffic. The ability of ductile iron pipe to distribute weight and pressure exerted by heavy traffic loads is a result of its high strength. This reduces the risk of deformation or failure, making it a reliable option for transporting water, sewage, and other fluids in areas commonly frequented by heavy vehicles. Moreover, ductile iron pipe displays excellent corrosion resistance, further enhancing its performance in high traffic areas. It can withstand exposure to various environmental conditions, such as moisture, chemicals, and abrasion, without compromising its structural integrity. This durability translates into minimal maintenance requirements and a long service life, making it a cost-effective solution. In addition, the smooth internal surface of ductile iron pipe minimizes friction and allows for efficient flow of liquids. This reduces energy consumption and maximizes the hydraulic capacity of the pipe, which is particularly advantageous in areas with high traffic loads where the demand for water or wastewater transportation is often high. To summarize, ductile iron pipe is a reliable and durable choice for areas with high traffic loads. Its strength, resistance to bending and cracking, corrosion resistance, and efficient flow characteristics make it an excellent option for transportation systems in roadways, highways, and other heavily trafficked areas.

- Q: How can the ductile iron pipe elbow be fixed?

- The utility model relates to a groove connecting pipe which has the function of sealing and sealing, and mainly comprises three parts: a sealing rubber ring, a clamping band and a locking bolt. The inner rubber sealing ring is arranged on the outer side of the connecting pipe and is matched with the pre rolling groove, and then the outer ring is buckled on the rubber ring, and then can be fastened with two bolts. Because of the special sealing structure design of the rubber sealing ring and the clamp hoop, the groove connecting piece has good sealing property, and the sealing property is enhanced correspondingly with the increase of the fluid pressure in the pipe.

- Q: How are ductile iron pipes protected against internal corrosion?

- Ductile iron pipes are protected against internal corrosion through a process called cement mortar lining. This involves applying a layer of cement mortar to the inner surface of the pipe, creating a protective barrier between the iron and the water flowing through it. This lining helps to prevent the formation of rust, corrosion, and scale build-up, ensuring the longevity and durability of the pipes.

- Q: What is the average weight of ductile iron pipes?

- The weight of ductile iron pipes can differ based on their specific dimensions and specifications. However, as a general rule, the weight of ductile iron pipes usually falls within the range of 50 to 200 pounds per foot. Various factors, including the pipe's diameter, wall thickness, and length, affect its weight. It is essential to understand that these weights are averages, and the actual weight of a particular ductile iron pipe may differ. To accurately determine the weight of a ductile iron pipe, it is recommended to consult the manufacturer's specifications or engineering guidelines.

- Q: Can ductile iron pipes be used for geothermal energy systems?

- Yes, ductile iron pipes can be used for geothermal energy systems. Ductile iron is a strong and durable material that can withstand the high temperatures and pressures often associated with geothermal energy systems. Its resistance to corrosion and high tensile strength make it an ideal choice for transporting geothermal fluids. Additionally, ductile iron pipes can be easily joined, allowing for flexibility and adaptability in design and installation. Overall, ductile iron pipes are a reliable and cost-effective option for geothermal energy systems.

- Q: Can ductile iron pipes be used in acidic environments?

- Yes, ductile iron pipes can be used in acidic environments. Ductile iron has excellent resistance to corrosion, including acidic conditions, due to its protective oxide layer. This makes it a suitable choice for applications in which exposure to acids is expected.

- Q: What is the manufacturing process of ductile iron pipes? Thank you

- Pig iron function: pig iron is strong, wear-resisting, good forging, but pig iron is crisp, cannot forge. Most frequently used: ductile iron covers, ductile iron pipes, ductile iron pipe fittings, ductile iron pipes are widely used in our life.

- Q: Can ductile iron pipe be used for oil and gas pipelines?

- Yes, ductile iron pipe can be used for oil and gas pipelines. Ductile iron pipe is known for its strength, durability, and corrosion resistance, making it suitable for a variety of applications including oil and gas transportation. It has been widely used in the industry for many years and has proven to be a reliable choice for pipeline systems. Additionally, ductile iron pipe can handle high pressure and heavy loads, making it suitable for the demands of oil and gas pipelines. However, it is important to ensure that the specific grade and specifications of the ductile iron pipe meet the requirements of the particular oil and gas project to ensure optimal performance and longevity.

- Q: Can ductile iron pipe be used for pump stations?

- Yes, ductile iron pipe can be used for pump stations. Ductile iron pipe is known for its durability and strength, making it suitable for high-pressure and heavy-duty applications such as pump stations.

- Q: How are ductile iron pipes made?

- Ductile iron pipes are made through a process called centrifugal casting. In this method, molten iron is poured into a rapidly spinning mold, which forces the iron to evenly distribute along the walls of the mold. As the mold continues to spin, the iron cools and solidifies, forming a hollow cylindrical shape. This process allows the iron to retain its strength and flexibility, making it suitable for use in various piping applications.

Send your message to us

Ductile Iron Pipes & Factory Prices C25 EN545/EN598/ISO2531 DN300

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords