All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

Are ductile iron pipes suitable for areas with high soil salinity?

Yes, ductile iron pipes are generally suitable for areas with high soil salinity. Ductile iron is highly resistant to corrosion, making it a reliable choice for environments with high levels of salt in the soil. This material can withstand the corrosive effects of salt and provide long-lasting performance in such conditions.

Can ductile iron pipe be used for desalination plants?

Yes, ductile iron pipe can be used for desalination plants. Ductile iron pipe is highly resistant to corrosion and has excellent strength and durability, making it suitable for the harsh operating conditions of desalination plants. Additionally, it offers ease of installation and maintenance, making it a practical choice for transporting water in these facilities.

What is the difference between push-on and mechanical joint ductile iron pipes?

Push-on and mechanical joint ductile iron pipes differ primarily in their method of connection or jointing.

Push-on ductile iron pipes have a simple and quick jointing system that involves a rubber gasket and a spigot end. The spigot end of one pipe is inserted into the socket end of the adjacent pipe, and a rubber gasket is placed between them to create a watertight seal. This jointing method does not require additional equipment or tools, making it easier and faster to install.

On the other hand, mechanical joint ductile iron pipes rely on a more robust and secure jointing mechanism. They use a mechanical joint assembly consisting of a gland, a retainer gland, and a bolt or nut. The spigot end of one pipe is inserted into the bell end of the adjacent pipe, and the mechanical joint assembly is tightened to create a tight and reliable connection. This jointing method provides greater resistance to external forces and is commonly used in applications where higher pressure or heavy loads are anticipated.

In summary, while both push-on and mechanical joint ductile iron pipes are made of the same material, their jointing systems differ in terms of simplicity, speed of installation, and strength of connection. The choice between the two depends on various factors such as the specific application requirements, pressure ratings, and the expected forces acting on the pipes.

Are ductile iron pipes suitable for use in chemical plants?

Yes, ductile iron pipes are suitable for use in chemical plants. Ductile iron is highly resistant to corrosion and can withstand the harsh chemicals and temperatures typically found in chemical plants. Additionally, ductile iron pipes have high strength and durability, making them a reliable choice for transporting various chemicals within the plant.

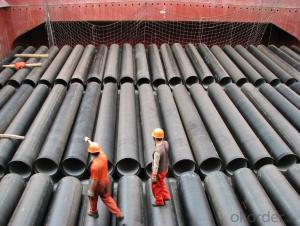

Wholesale Ductile Iron Pipes from supplier in Serbia

Whether you require Ductile Iron Pipes for water supply, sewerage, or industrial applications, we have the expertise to assist you in finding the right products for your specific requirements. Our team of knowledgeable professionals is dedicated to providing exceptional customer service and ensuring that you receive the highest quality products at competitive prices.

In addition to our sales and procurement services, we also offer technical support to help you with any inquiries or concerns you may have. Whether you need assistance with product specifications, installation guidelines, or maintenance requirements, our experts are here to assist you every step of the way.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and partnerships, enabling us to source and deliver high-quality Ductile Iron Pipes efficiently and reliably. Our commitment to excellence and customer satisfaction has earned us a reputation as a trusted supplier in the Serbian market.

Contact us today to discuss your Ductile Iron Pipes requirements in Serbia. Let us be your partner in success and provide you with the best solutions for your projects.

In addition to our sales and procurement services, we also offer technical support to help you with any inquiries or concerns you may have. Whether you need assistance with product specifications, installation guidelines, or maintenance requirements, our experts are here to assist you every step of the way.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and partnerships, enabling us to source and deliver high-quality Ductile Iron Pipes efficiently and reliably. Our commitment to excellence and customer satisfaction has earned us a reputation as a trusted supplier in the Serbian market.

Contact us today to discuss your Ductile Iron Pipes requirements in Serbia. Let us be your partner in success and provide you with the best solutions for your projects.

Hot Search

- Ductile Iron Pipes in Finland

- Ductile Iron Pipe Fittings in Paraguay

- Ductile Iron Pipe Fittings in Tuvalu

- Ductile Iron Pipe Fittings in Nicaragua

- Ductile Iron Pipes in Turkmenistan

- Ductile Iron Pipe Fittings in Liechtenstein

- Ductile Iron Pipes in Kazakhstan

- Ductile Iron Pipes in Andorra

- Ductile Iron Pipe Fittings in Nigeria

- Ductile Iron Pipe Fittings in Latvia