ISO2531 Socket Spigot Ductile Iron Pipe K8

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 Meter m

- Supply Capability:

- 250000 Ton Per Year m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

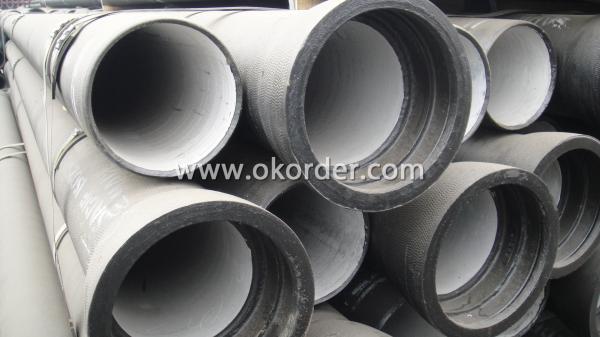

General Introduction and Specifications of ISO2531 Socket Spigot Ductile Iron Pipe K8

Standard: Pipes according to ISO2531/EN545

Joint: T Type joint

Size: DN80-DN2000

Effective length: 6m/pc or 5.7m/pc or 5.5m/pc

Internal lining: cement mortar lining comply with ISO4179

External coating: sprayed metallic Zinc coating (min.130g/m2) according to ISO8179 + bitumen painting (min.70μm) according to BS3416.

Gasket: Matched 100% natural rubber gasket in accordance with ISO4633.

Applications of ISO2531 Socket Spigot Ductile Iron Pipe K8

Design Flexibility: Pipes will safely function over a wide range of operating pressure, trench loads and installation conditions. Standard design includes generous factor of safety to protect against unknowns.

Easier Handing: Ductile Iron Pipes can be more easily maneuvered under and around existing underground obstructions, thereby eliminating unnecessary changes in line or grade.

Superior Joints: Easily assembled push in joints speed job progress, minimize installation cost. Joint remains leakproof under all operating pressures.

A complete Range: Ductile Iron Pipes are available with complete range of fittings and accessories in size from 80 to 2000mm dia. And a variety of lining and coatings for varied service conditions.

Standard Wall Thickness of ISO2531 Socket Spigot Ductile Iron Pipe K8

Nominal Wall Thickness of pipe:

e=K(0.5+0.001*DN)

Where, DN: Nominal diameter; K: Coefficient(K=7,8,9,10,11,12...)

Nominal Wall Thickness of pipe fittings:

e=7+0.014*DN (K=14)

e=6+0.012*DN (K=12)

Packing, Delivery and transport of ISO2531 Socket Spigot Ductile Iron Pipe K8

Show for ISO2531 Socket Spigot Ductile Iron Pipes K8

- Q: Can ductile iron pipes be used for pressure relief systems?

- Yes, ductile iron pipes can be used for pressure relief systems. Ductile iron pipes are known for their strength, durability, and ability to withstand high pressures. They are commonly used in various applications, including pressure relief systems, where they can effectively handle and dissipate excess pressure to ensure the safety and functionality of the overall system.

- Q: What are the different methods for testing ductile iron pipe?

- There are several methods available for testing ductile iron pipe to ensure its quality and reliability. These methods include: 1. Hydrostatic Testing: This is the most common method used for testing ductile iron pipe. It involves filling the pipe with water and pressurizing it to a specified level. The pipe is then inspected for any leaks or deformations under the applied pressure. Hydrostatic testing helps determine the pipe's ability to withstand internal pressure without failure. 2. Tensile Testing: This method involves subjecting a sample of the ductile iron pipe to a gradually increasing tensile load until it fractures. The test measures the ultimate tensile strength, yield strength, and elongation of the material. Tensile testing helps evaluate the pipe's mechanical properties and its ability to withstand tension without breaking. 3. Hardness Testing: This method measures the hardness of the ductile iron pipe using various techniques such as Brinell, Rockwell, or Vickers hardness tests. Hardness testing provides information about the material's resistance to deformation, wear, and fatigue. It helps assess the pipe's durability and resistance to external forces. 4. Impact Testing: This method involves striking a notched sample of the ductile iron pipe with a pendulum or falling weight to measure its impact resistance. The test determines the material's ability to absorb energy during sudden loading or impact. Impact testing helps evaluate the pipe's ability to withstand accidental impacts or dynamic loads. 5. Ultrasonic Testing: This non-destructive testing method uses high-frequency sound waves to detect internal defects or discontinuities in the ductile iron pipe. Ultrasonic testing can identify voids, cracks, or inclusions that may affect the pipe's structural integrity. It helps ensure the pipe's soundness and reliability. 6. Magnetic Particle Testing: This method is primarily used for detecting surface or near-surface defects in the ductile iron pipe. It involves applying a magnetic field to the pipe and then applying magnetic particles to the surface. Any defects present will cause the magnetic particles to gather and form visible indications. Magnetic particle testing helps identify surface cracks, laps, or other defects that may affect the pipe's performance. These different testing methods help ensure that ductile iron pipe meets industry standards and specifications, ensuring its quality and reliability in various applications.

- Q: What is the expected joint restraint method for ductile iron pipes?

- The expected joint restraint method for ductile iron pipes is typically mechanical joint restraints, such as gland and follower glands or wedge-action restraints, which provide a secure and reliable connection while allowing for expansion and contraction of the pipes.

- Q: How are ductile iron pipes different from PVC pipes?

- Ductile iron pipes and PVC pipes are utilized extensively in plumbing and water distribution systems, but they differ significantly in terms of their composition and properties. Ductile iron pipes are crafted from a particular form of cast iron that contains graphite nodules, which provide the material with ductility and flexibility. Consequently, these pipes can endure high pressures and heavy loads without succumbing to breakage or cracking. Ductile iron pipes are renowned for their robustness and longevity, making them particularly suitable for underground applications and areas with substantial traffic. Conversely, PVC pipes are constructed from a plastic known as polyvinyl chloride. These pipes possess rigidity and lack the same level of strength as ductile iron pipes. PVC pipes are commonly employed in low-pressure scenarios, such as residential plumbing systems, irrigation, and drainage systems. These pipes are lightweight, easy to install, and resistant to corrosion, rendering them a favored option for residential and non-industrial purposes. The cost disparity between ductile iron pipes and PVC pipes represents another distinction. Due to higher material and production expenses, ductile iron pipes tend to be pricier. Conversely, PVC pipes are relatively inexpensive to manufacture, making them a cost-effective choice for numerous plumbing projects. In summary, the primary disparities between ductile iron pipes and PVC pipes involve their composition, strength, flexibility, and cost. Ductile iron pipes, formed from cast iron, are celebrated for their strength and durability, while PVC pipes, formed from plastic, are lighter and more cost-effective. The selection between these two types of pipes depends on the specific demands of the plumbing project, including pressure, load-bearing capacity, and budgetary considerations.

- Q: Can ductile iron pipes be used for underground storage tanks?

- Under specific circumstances, ductile iron pipes are appropriate for underground storage tanks. This material possesses strength and durability, effectively resisting corrosion and making it a suitable option for underground applications. Nevertheless, several factors must be taken into account before implementing ductile iron pipes for underground storage tanks. First and foremost, it is vital to evaluate the project's precise demands and regulations. Different regions and industries may enforce specific guidelines regarding the materials used in underground storage tanks. It is imperative to ascertain that ductile iron pipes comply with these regulations and meet the required standards for underground storage. Secondly, the size and capacity of the storage tank must be considered. Ductile iron pipes are available in various sizes, but their dimensions may not be suitable for large-scale storage tanks due to limitations. Consulting engineers or experts is necessary to determine the appropriate pipe size and capacity for the specific storage requirements. Lastly, the design and installation of the underground storage tank necessitate careful planning. Adequate measures should be taken to seal and protect against external factors such as soil movements, water pressure, or other potential hazards. Preventive actions should be implemented to avoid leaks or damage to the pipes, ensuring the safety and longevity of the storage tank. In conclusion, ductile iron pipes can be utilized for underground storage tanks, but it is crucial to consider the specific requirements, regulations, sizing limitations, and proper design and installation. Seeking guidance from professionals in the field and adhering to industry standards will ensure successful implementation of ductile iron pipes for underground storage tanks.

- Q: What is the expected internal lining material for ductile iron pipes?

- The expected internal lining material for ductile iron pipes is typically cement mortar lining or polyethylene lining. Cement mortar lining provides a protective coating to the interior surface of the ductile iron pipe, preventing corrosion and extending its lifespan. On the other hand, polyethylene lining is a thermoplastic material that offers resistance to corrosion, abrasion, and chemicals, making it suitable for applications where aggressive substances are present or when the water quality is poor. Both lining materials have their advantages and are commonly used in the industry, depending on the specific requirements and conditions of the project.

- Q: Can ductile iron pipes be used in gravity sewer systems?

- Yes, ductile iron pipes can be used in gravity sewer systems. Ductile iron is a strong and durable material that is commonly used in various applications, including sewer systems. It has excellent resistance to corrosion and can withstand high pressure and heavy loads. Additionally, ductile iron pipes have a smooth interior surface, which helps to reduce friction and improve the flow of waste and wastewater. Therefore, they are a suitable choice for gravity sewer systems, where the flow of sewage relies on gravity to move through the pipes.

- Q: Are ductile iron pipes resistant to biological growth?

- Yes, ductile iron pipes are generally resistant to biological growth. Ductile iron is a strong and durable material that is commonly used in water and sewage systems. Its smooth surface inhibits the growth of bacteria, fungi, and other microorganisms that can contribute to biological growth. Additionally, ductile iron pipes are often coated with protective linings or coatings, such as cement mortar or epoxy, which further enhance their resistance to biological growth. However, it is important to note that no material is completely immune to biological growth, and regular maintenance and cleaning of the pipes may still be required to ensure long-term resistance.

- Q: Can ductile iron pipe be used for water well applications?

- Yes, ductile iron pipe can be used for water well applications. Ductile iron has excellent strength, durability, and corrosion resistance, making it suitable for transporting water in various applications, including water well systems.

- Q: Can ductile iron pipes be used in mining applications?

- Ductile iron pipes are well-suited for incorporation into mining applications due to their exceptional strength and durability. Renowned for their ability to withstand rigorous environments, such as mines, ductile iron pipes offer excellent resistance to corrosion, a crucial characteristic when dealing with water or liquids that may contain chemicals or minerals. Furthermore, these pipes possess commendable impact resistance, enabling them to endure the harsh conditions commonly encountered in mining operations. Their ease of installation and maintenance further contribute to their efficiency and cost-effectiveness in mining applications. All in all, ductile iron pipes are a dependable choice for the transportation of water, slurry, or other substances within mining operations.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 1989 |

| Annual Output Value | Above US$ 3 Million |

| Main Markets | Mid East Europe; Eastern Asia; South Africa; |

| Company Certifications | ISO 9001:2008;ISO2531:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 2000 People |

| Language Spoken: | English; Chinese; Spain; Alabic |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 8 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

ISO2531 Socket Spigot Ductile Iron Pipe K8

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 Meter m

- Supply Capability:

- 250000 Ton Per Year m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords