Tool Steel H13/1.2344 Round Steel Bar Alloy Steel Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Tool Steel H13/1.2344 Round Steel Bar Alloy Steel Bar

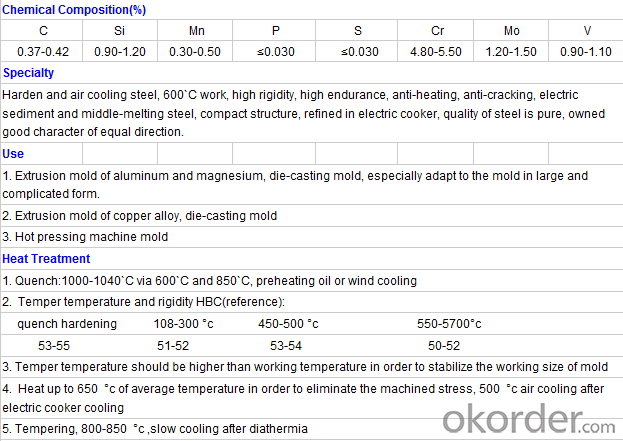

Product information:

H13/1.2344 round bar

1.Diameter:10mm~600mm,

2.Delivery Conditon:annealed, black/turned surface

3.Short Delivery Time

4.Payment:By 30% ,T/T in advanced payment or L/C at sight

5.Min qty:25MT

6.Dlivery terms:CFR or CIF

7.Delivery time:according to your qty

Product show

Workshop show

Our service:

-High manufacturing accuracy

-High strength

-Small inertia resistance

-Strong heat dissipation ability

-Good visual effect

-Reasonable price

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer's trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

If you need the sample, please feel free to let me know. Any question, we will contact you ASAP!

- Q: How does heat treatment affect the properties of special steel?

- Heat treatment can significantly impact the properties of special steel. By subjecting the steel to controlled heating and cooling processes, the structure and composition of the steel can be altered, resulting in changes to its hardness, strength, toughness, and other mechanical properties. Heat treatment can also improve the steel's resistance to wear, corrosion, and fatigue, making it more suitable for specific applications.

- Q: What are the different methods of preventing intergranular corrosion in special steel?

- There are several methods available to prevent intergranular corrosion in special steel. 1. Heat Treatment: One effective method is to subject the steel to a heat treatment process called solution annealing. This involves heating the steel to a high temperature and then rapidly cooling it. This process helps to dissolve any precipitates or carbides that may have formed along the grain boundaries, thus reducing the risk of intergranular corrosion. 2. Alloying: Another approach is to add specific alloying elements to the steel composition. For example, the addition of elements like chromium and molybdenum can enhance the steel's resistance to intergranular corrosion. These alloying elements form a protective oxide layer on the surface, preventing corrosion from occurring along the grain boundaries. 3. Passivation: Passivation involves treating the steel surface with chemicals that create a protective layer. This layer acts as a barrier, preventing the corrosive environment from reaching the grain boundaries. Commonly used passivation techniques include acid pickling and electrochemical methods. 4. Sensitization Control: Special attention must be given to the sensitization process, which occurs when the steel is exposed to high temperatures for a prolonged period. This can lead to the precipitation of chromium carbides along the grain boundaries, making the steel susceptible to intergranular corrosion. By carefully controlling the heating and cooling rates during processing, sensitization can be minimized or prevented. 5. Corrosion Inhibitors: Another option is to use corrosion inhibitors, which are chemicals that can be applied to the steel surface to protect it from corrosion. These inhibitors form a protective film on the surface, preventing the corrosive agents from attacking the grain boundaries. It is important to note that the specific method used will depend on the type of special steel and the intended application. The selection of the most appropriate method should be based on a thorough understanding of the steel's composition, processing conditions, and the anticipated corrosive environment.

- Q: What are the main applications of special steel in the automotive electrical systems?

- Special steel is widely used in automotive electrical systems for various applications. One of the main uses is in the production of electrical connectors and terminals, where special steel offers excellent conductivity and corrosion resistance. Additionally, special steel is utilized in the manufacturing of electrical contacts, relays, and switches, ensuring reliable and efficient performance in the automotive electrical systems.

- Q: How does special steel perform in terms of weldability?

- Special steel generally performs well in terms of weldability. It has good ductility and can be easily welded using various welding methods such as arc welding, resistance welding, and laser welding. The composition and properties of special steel are specifically designed to ensure that it can be successfully welded without compromising its strength and integrity. However, the specific weldability of special steel may vary depending on its exact composition and specific grade. It is always recommended to consult the manufacturer's guidelines and follow proper welding procedures to achieve the best results when working with special steel.

- Q: What are the different annealing techniques used for special steel?

- There are several annealing techniques used for special steel, including full annealing, process annealing, and stress relief annealing. Full annealing involves heating the steel to a temperature above its critical point and then slowly cooling it, resulting in a refined grain structure and improved mechanical properties. Process annealing is a similar technique used to soften the steel after cold working or hot working processes. Stress relief annealing is used to reduce residual stresses in the steel by heating it to a temperature below its critical point and then gradually cooling it. These different annealing techniques are employed based on the specific requirements of the special steel and the desired outcome.

- Q: What are the challenges in heat treating special steel?

- One of the challenges in heat treating special steel is achieving the desired hardness and strength while maintaining dimensional stability. Special steels often have complex alloy compositions that require precise heat treatment processes to achieve the desired properties. Another challenge is controlling the transformation temperatures and rates, as special steels may have multiple phase transformations that need to be precisely controlled to avoid distortion or cracking. Additionally, special steels may have high hardenability, making it difficult to achieve uniform hardness throughout the part. Overall, heat treating special steel requires a deep understanding of its composition and careful control of the heat treatment parameters to overcome these challenges and achieve the desired properties.

- Q: Can special steel be used in the medical field?

- Yes, the medical field utilizes special steel. Special steel alloys, including but not limited to stainless steel, find extensive application in medical and surgical instruments, implants, and equipment. Stainless steel is selected for its remarkable resistance to corrosion, exceptional strength, and enduring durability. It is commonly employed in surgical instruments like scalpels, forceps, and needles, as well as in orthopedic implants like bone screws and plates. Moreover, special steel alloys are employed in the fabrication of medical equipment such as MRI machines and X-ray tables, where high strength and magnetic properties are imperative. In summary, special steel plays a pivotal role in the medical field owing to its distinctive characteristics and capacity to meet stringent criteria for hygiene, safety, and dependability.

- Q: How does special steel resist wear and tear?

- Special steel resists wear and tear due to its unique composition and manufacturing process. It is made with a higher percentage of alloying elements such as chromium, nickel, and molybdenum, which enhance its hardness, strength, and corrosion resistance. This increased hardness enables the steel to withstand abrasion, friction, and impact, making it highly durable and resistant to wear and tear. Additionally, special steel undergoes specialized heat treatments and mechanical processes that further enhance its toughness and resistance to deformation, contributing to its ability to withstand harsh and demanding conditions without significant deterioration.

- Q: What properties make special steel unique?

- Special steel is unique due to its exceptional properties such as high strength, excellent corrosion resistance, superior heat resistance, and remarkable wear resistance. It possesses a combination of various alloying elements like chromium, nickel, molybdenum, and vanadium, which enhance its mechanical properties and make it suitable for a wide range of applications in industries such as automotive, aerospace, and construction. Additionally, special steel can be tailored through precise manufacturing processes to exhibit specific characteristics, making it a versatile and highly sought-after material.

- Q: How does special steel contribute to improved product performance?

- Special steel contributes to improved product performance in several ways. Firstly, special steel is known for its exceptional strength and durability. This allows products made from special steel to withstand heavy loads, high temperatures, and harsh environments without deforming or breaking. This enhanced strength and durability result in a longer product lifespan and reduced maintenance requirements. Additionally, special steel possesses excellent corrosion resistance properties. It is less susceptible to rust and other forms of corrosion, making it ideal for products that are exposed to moisture or chemicals. This corrosion resistance ensures that the product remains in optimal condition, even in corrosive environments, and reduces the need for frequent replacements. Special steel also offers superior heat resistance. It can withstand extreme temperatures without losing its mechanical properties, such as strength and hardness. This makes it suitable for products that operate in high-temperature conditions, such as engines, turbines, and exhaust systems. The ability of special steel to retain its properties at elevated temperatures significantly improves product performance and reliability. Furthermore, special steel can be tailored to meet specific requirements through different alloying elements and heat treatment processes. This customization allows manufacturers to fine-tune the material properties to suit the intended application, leading to improved product performance. For example, by adjusting the alloying elements, special steel can exhibit improved wear resistance, impact resistance, or hardness, depending on the desired application. In summary, special steel contributes to improved product performance by providing exceptional strength, durability, corrosion resistance, heat resistance, and customization options. These properties enhance the product's lifespan, reliability, and performance under challenging conditions, ultimately benefiting the end-users.

Send your message to us

Tool Steel H13/1.2344 Round Steel Bar Alloy Steel Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords